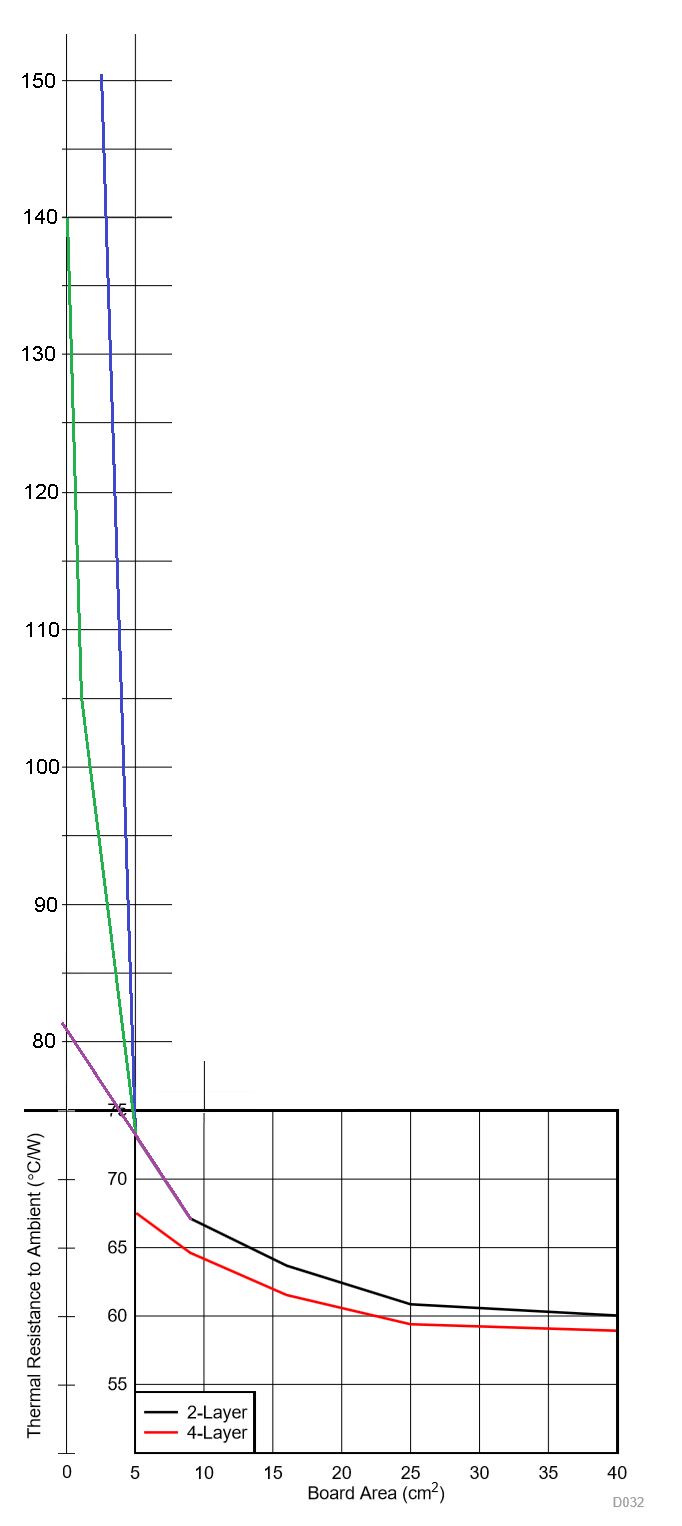

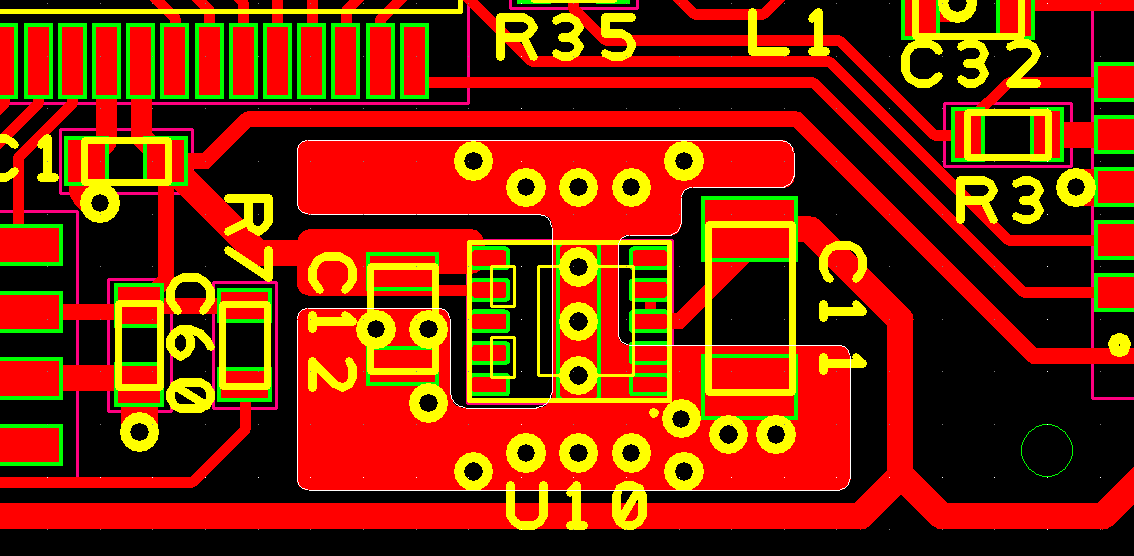

In the datasheet, Figure 7 and Figure 69. Package Thermal Resistance vs Board Copper Area, No Air Flow both express the Board Copper Area in square CENTImetres.

Could you please confirm if this is correct or that this should be square millimeters (which makes way more sense)?