Hi,

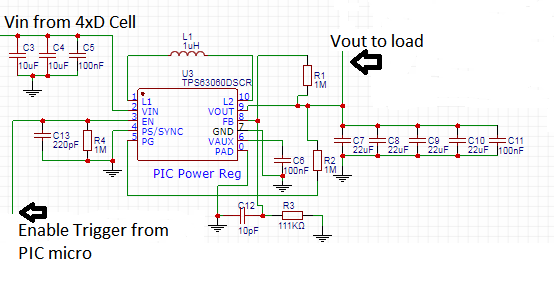

We are using TPS63060 to maintain a switched power supply of 5.0VDC for our embedded modem that is on the main board.

Source of power for TPS63060 and main board: 4 x D cell ( alkaline)=6.1 VDC

Power requirement for modem when powered ON: averages about 175mA @ 5VDC and peaks to 300mA at transmit, we need the modem ON for 10 seconds or so to transmit and is turned OFF totally after , via the EN enable/disable on TPS6360.

We have about 10 PCB that we have fabricated per the layout and schematics shown below ( with 4 fingers on each side on the belly/thermal pad). Each board is exhibiting a different Vout characteristics for the TPS63060. For initial testing we have EN for TPS63060 always high/enables and not toggling EN to create switched output from TPS63060 ( EN of TPS63060 is set high by the PIC18F4620 micro controller on the main board).

a. Some boards have initial Vout of 5.1VDC (with minimal load of 1-3 MOhm resistor), but with the modem as load, Vout does a nose dive and Vout drops to about 2VDC, the modem powers off at around 3.5 VDC and hence no load but Vout never rebounds back.

b. On some of the other boards from the same lot Vout maintains 5.1VDC with the modem present as load, but only on the second power cycle, in other words: power on main boards from D cells, main board working but Vout of TPS=0 to 0.2VDC. Reboot the power and it works the second time and maintains 5.0VDC. After the second power cycle EN on/off consistently gives desired Vout. But why the need for second power cycle?? Its almost like some of the caps needs to get some charge built up, so with the charge built up present on the second power cycle it works. If I power off the board for a few minutes and retry same problem ....needs a power cycle. But if I retry within few seconds it does not need the second power cycle

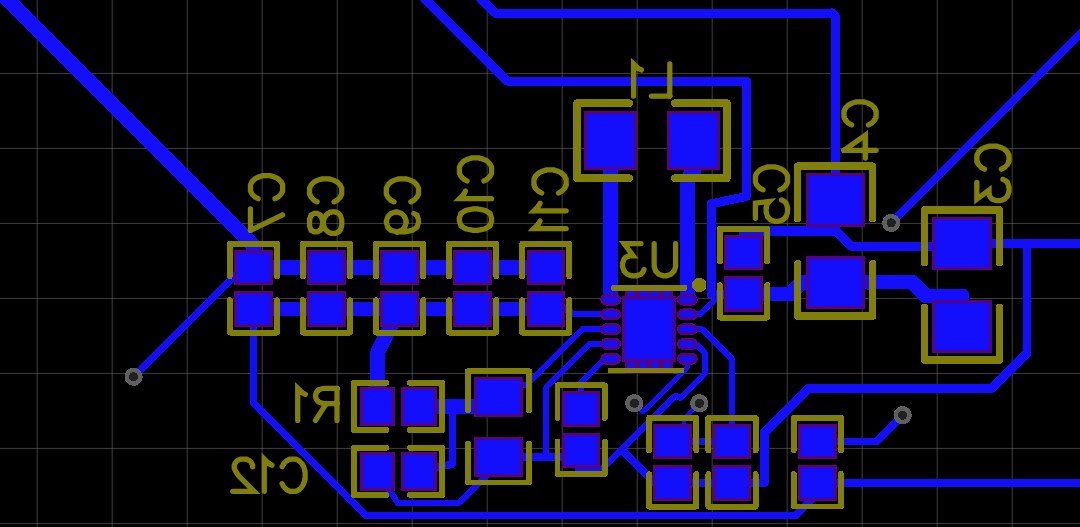

Figure 1: Schematics

Figure 2: Partial PCB layout of the TPS63060 components only.

Please advise!