Other Parts Discussed in Thread: INA302, LM5050-2, BQ76925, BQ76930

Hi,

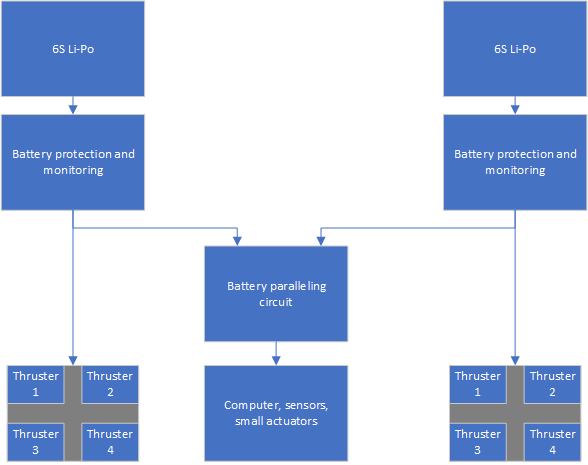

I'm from the University of Florida. I have a robot that has 8 thrusters, a computer, and several sensors, cameras, and other small actuators. We have been running with a 48V rail comprised of two 6S LiPos in series. We're changing thrusters so we're switching to a 24V rail and taking the two batteries we're running in series and running them in parallel. We're taking this opportunity to finally add in battery protection. This is an area I do not have much experience with so I am looking for advice.

The overall topology I'm imagining something like this:

The biggest thing I want to protect against is over-discharging, or under-volting, the batteries. For at least this initial version, we will continue to remove the batteries and put them on a dedicated charger. This circuit only needs to protect against discharging events. OT and OC protection would be nice. We'd also like to be able to monitor the battery voltage and current.

This is what I'm thinking based on what I've found poking around TI's website:

Battery protection:

The BQ77915 looks like a chip that would meet and exceed our needs, but we'd have to use two because our batteries are 6S and put multiple FETs in parallel because our maximum power draw at nominal 24V is 1200W per battery.

Alternatively, I was thinking we might have to implement a solution where we monitor the battery voltage with a uC and then cut power if the batteries get too low. We have a relay on each thruster that we used for our "kill" functionality and we could add a relay to the computer/sensor power. The benefit here would be that we don't have to do FET paralleling but the disadvantage would be the time to design and test the circuit.

Battery monitoring:

We have a separate circuit that does this that we've used on other vehicles in our lab. It is based on the INA302

Battery paralleling:

We've used the LM5050-2 to do this before, we plan on continuing to use the chip on this vehicle as well.