Dear TI:

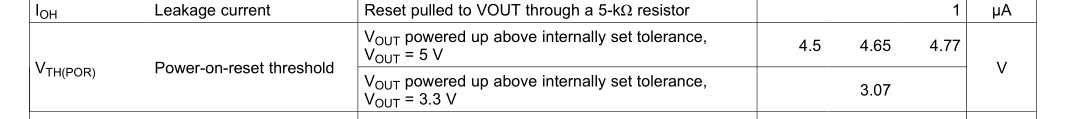

Custom use tps7a6350-q1 for ESD Test, But it fauiled ----nReset pin output low voltage.and external light blink one time.

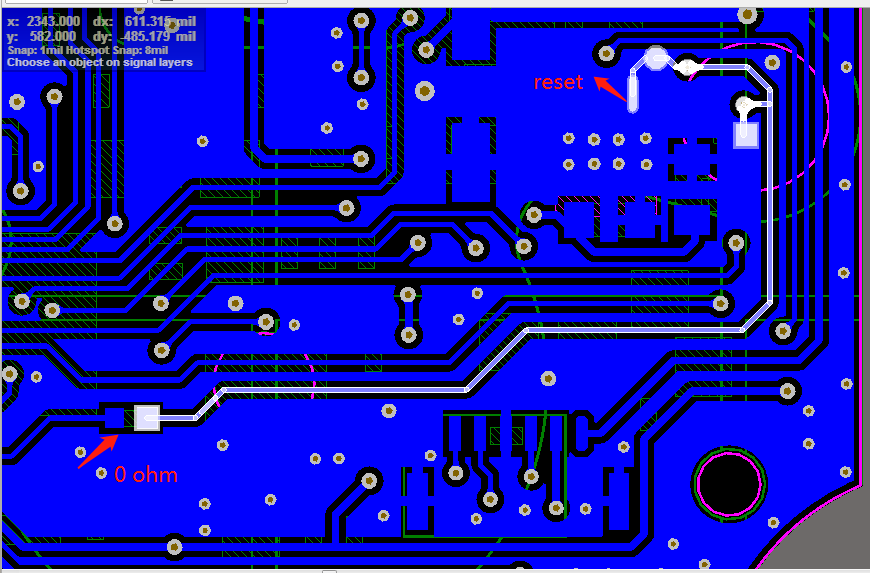

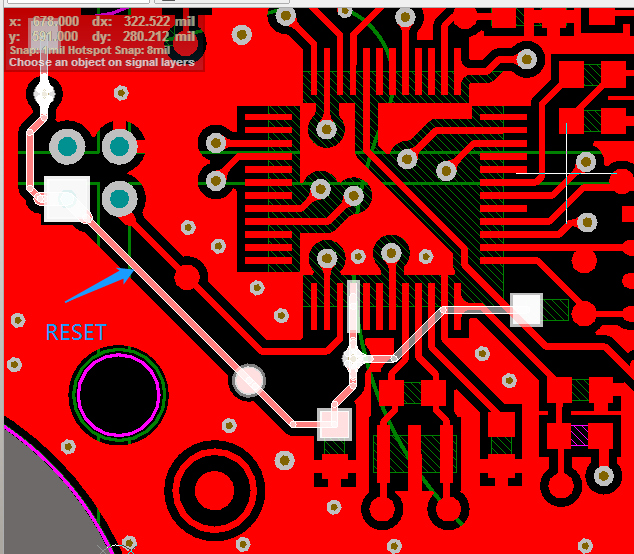

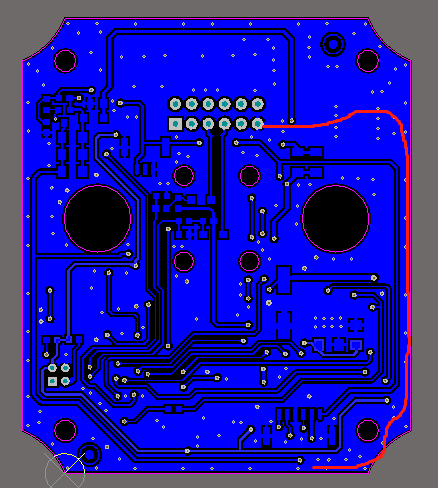

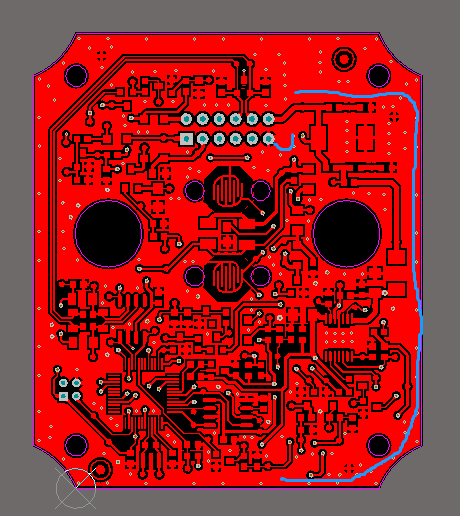

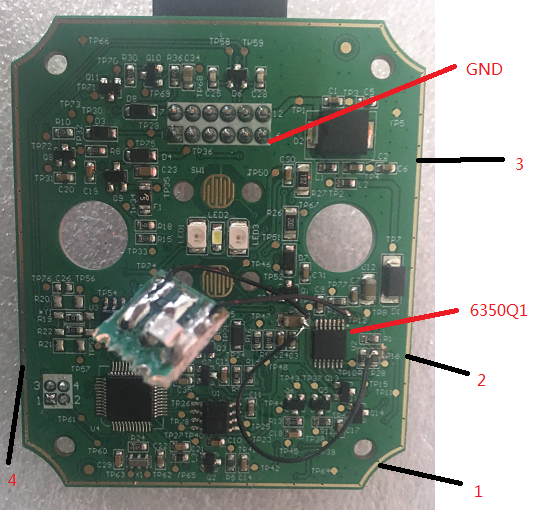

the output cap is 10uf*3=30uf. I Double may the bad PCB layout cause the problem.

the test condition:

ESD Voltage : 2kv /4kv ...

I Double the interruption from the nReset net. Cause the 5v output voltage (white led) has no blink.