Other Parts Discussed in Thread: , LMZM33603

Hello,

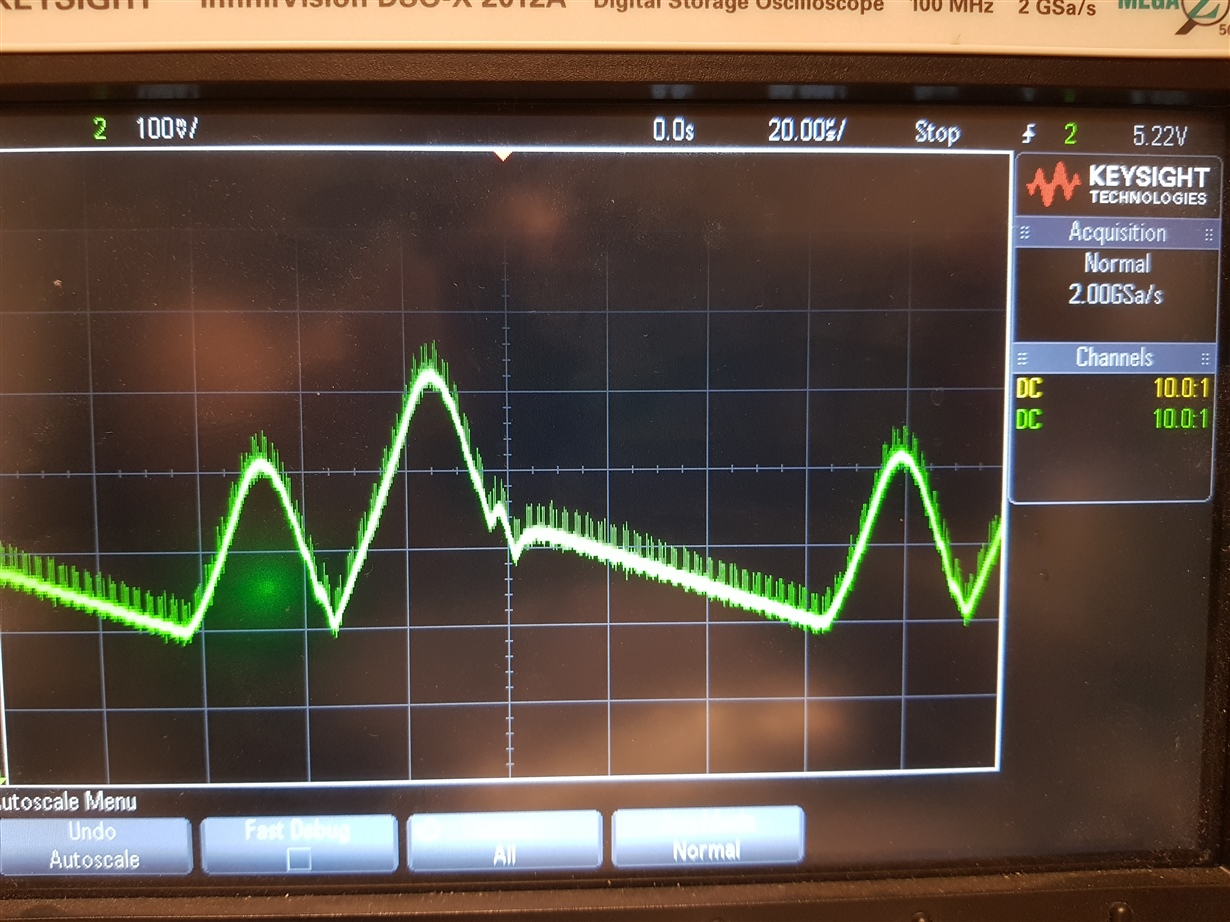

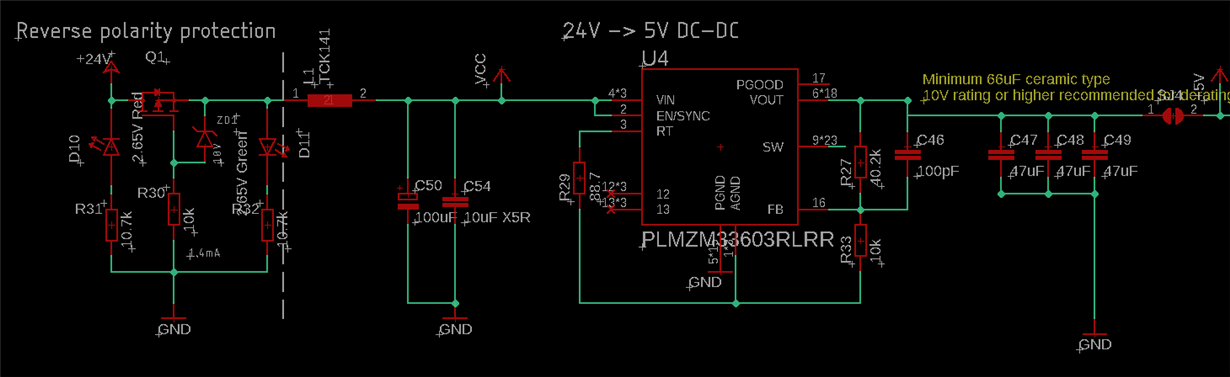

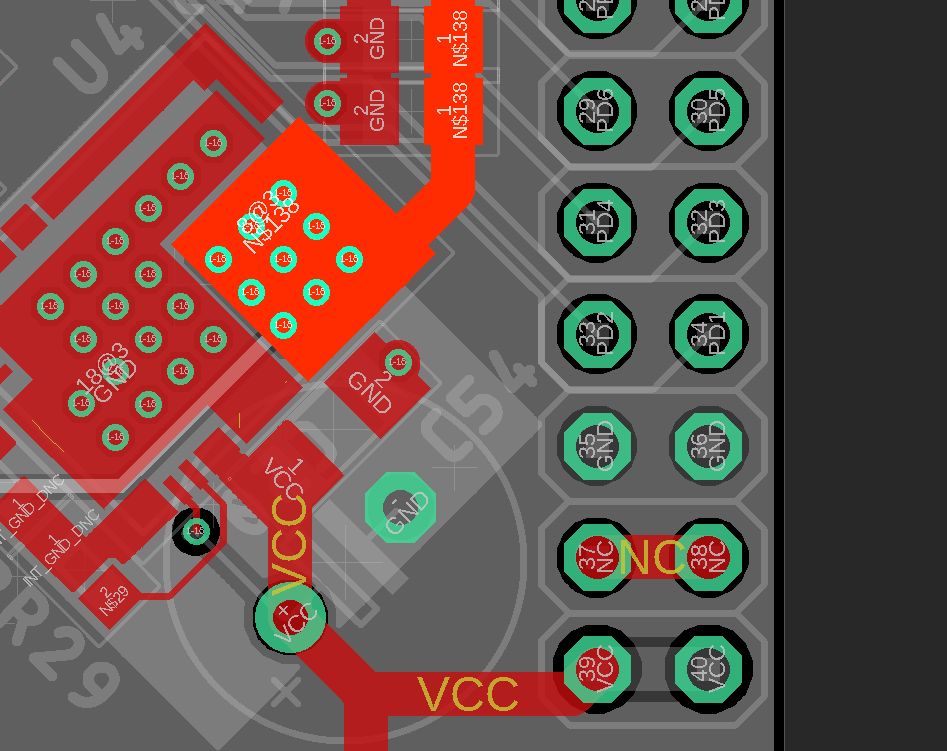

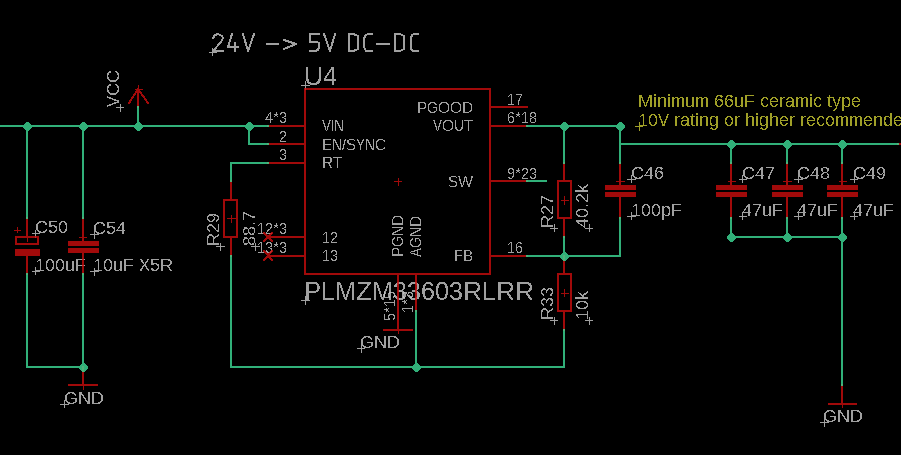

I have integrated the mentioned DC-DC power supply into a board. However upon booting it up I've noticed it gets fairly hot to the touch while the load is barely 500mA @ 5V. Is this normal for this particular chip or is there something wrong in the design?

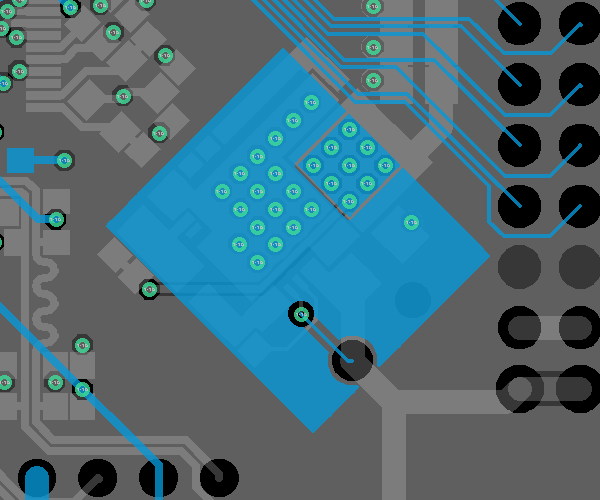

I've attached the schematic used. The chip that is being used is the 2A version, not the 3A like the schematic suggests.

Frank