Part Number: BQ20Z95

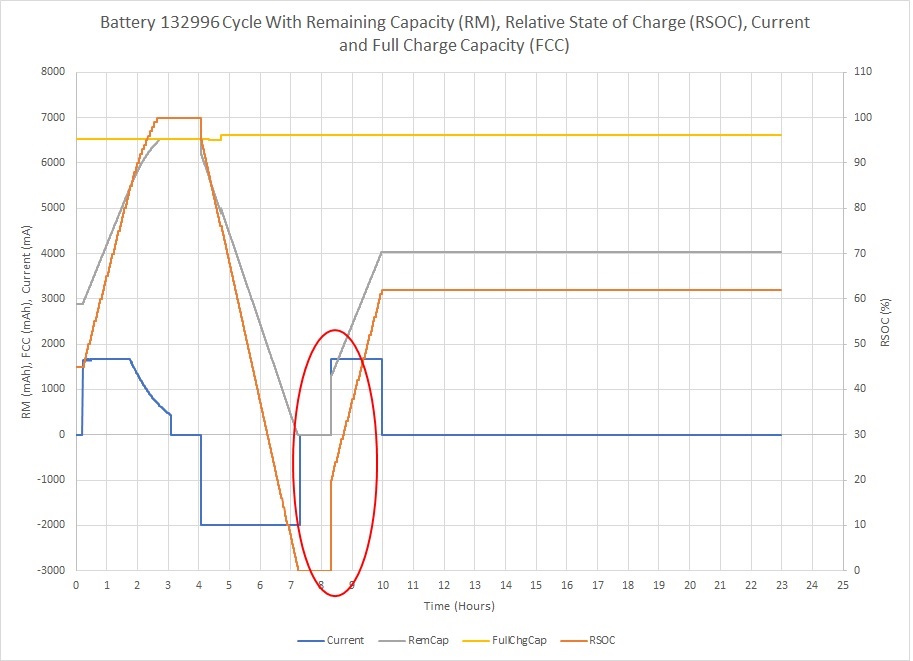

On one of our product lines, we are experiencing occasional fallout for inaccurate RSOC when the battery has been cycled. We cycle the battery through a full charge/discharge cycle, then charge it to 30% state of charge based on added capacity. In one of the failure modes for RSOC failure, when 30% of battery capacity is added, the battery comes back reporting RSOC at 60%.

When the battery was cycled with SMBUS being captured, it was found that when the battery is charging from RM = 0mAh, RM jumps to 1300mAh as soon as charge current is supplied. The protection PCBA is based on the reference design for this gas gauge. Can you provide any insight on why this might be occurring on the particular battery? I have attached the SMBUS log along with flash readings for every five minutest that the battery was runnining and a senc file pulled when the cycle test was completed.