Other Parts Discussed in Thread: , BQSTUDIO, BQMTESTER, BQPRODUCTION, BQ40Z50-R2

We have a battery management solution based on the BQ40Z60, having our own custom hardware. Schematic is very similar to the one of BQ40Z60EVM-578, the PCB has passed EMC and is not going to change. The pack is a 2P4S configuration of ICR18650-26F cells.

The protection, gauging, etc parameters have been set up as needed for our application. We are able to complete learning cycles successfully.

The setup functions, but we have two persistent problems with it.

One is simply that the full charge capacity of the pack is showing up low. We usually get something around 4500mAh displayed in bqStudio although it should be 5200mAh (2x2600mAh). Sadly it’s valid and not just displayed incorrectly, manually integrating passed charge gives the same results. Cell Qmax values are always over 5500mAh. I’ve already been playing around with IT gauging config settings, but it did not help. The only way I was ever able to raise full charge capacity to still a bit below 5000mAh, is by raising charge end voltages to (or even a bit above) 4200mV after doing the learning cycle at a 4100mV setting. It seemed like if the learning cycle is already done at a 4200mV setting, we get the same low capacity. Regarding chemistry, there are 2 different IDs for the ICR18650-26F (0137, 1165). Which one is supposed to be used? Do you have any other idea that can cause a problem like this?

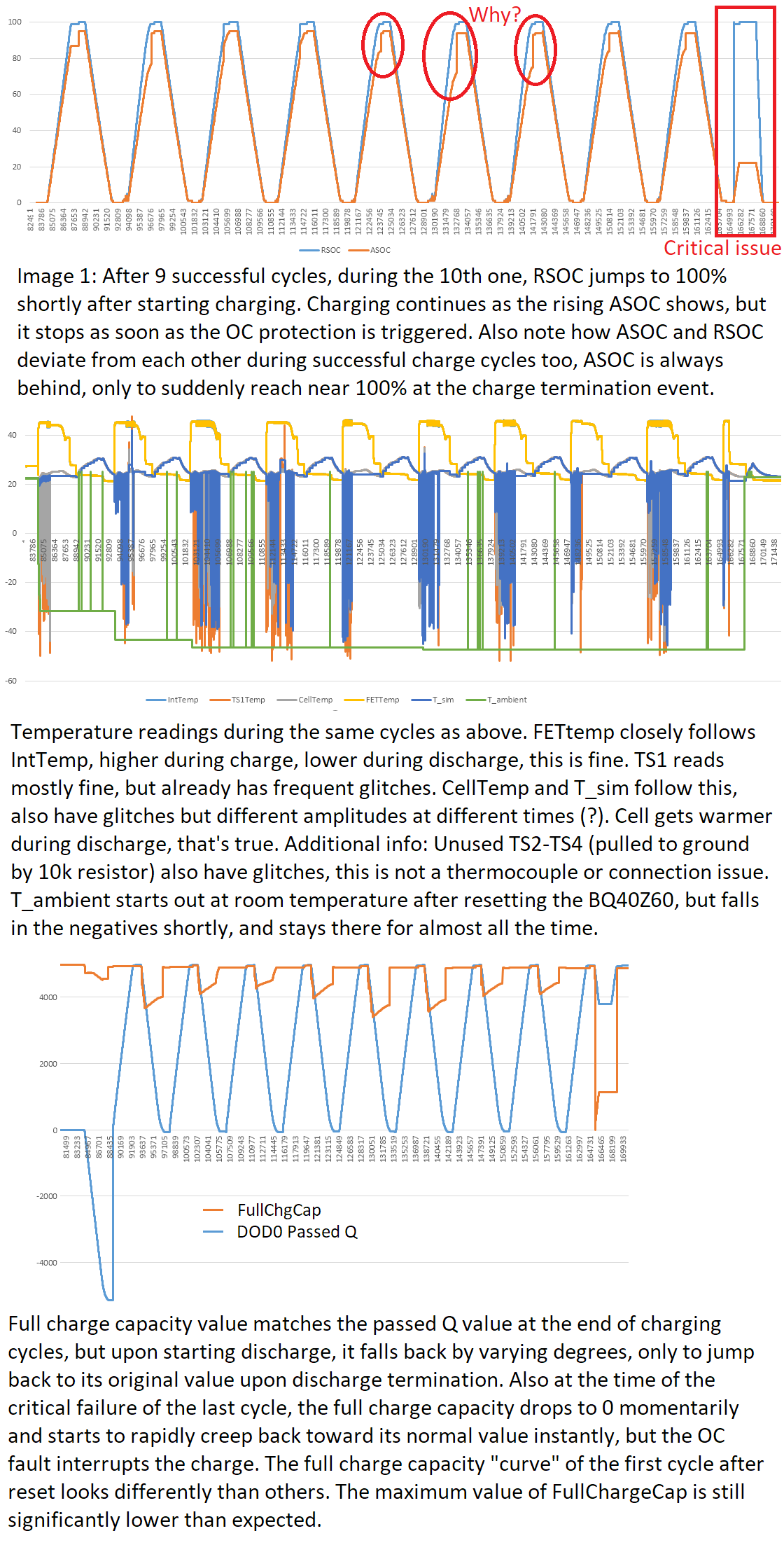

The other issue we’ve observed, is that during charging, RSOC sometimes jumps up a rather large step to 100%. During discharge, gauging is perfect. We could live with the incorrect RSOC display, but this artifact makes the overcharge protection unusable, since charge passed after the RSOC=100% mark is considered overcharge even though ASOC is still lower and climbing. If we set the OC threshold to a reasonably low value, it is going to be triggered and cause a safety status shutdown. Again, playing with IT CFG settings regarding RSOC manipulation solved nothing. Something suspicious I found, is that the T_sim and T_ambient temperature values are often in the deep negatives, -10 to -50°C even though TS1(cell temp) and T_Int reads correctly (around 26°C room temp). And reading through the logged data, the RSOC jump to 100% sometimes coincided with a jump or glitch in some of the temperature values. Any idea for this?

I’m attaching an image to back up what I’m describing. Really looking forward to a suggestion how to solve (or workaround) these issues.

I'm also linking the gg.csv of the setup and a data log sheet if the forum file upload happens to function.

Thanks a lot,

Tamas