Other Parts Discussed in Thread: TPS62808, TPS62801, TPS62743

Hi,

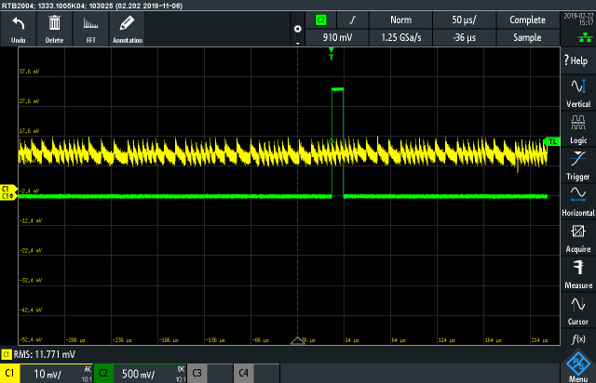

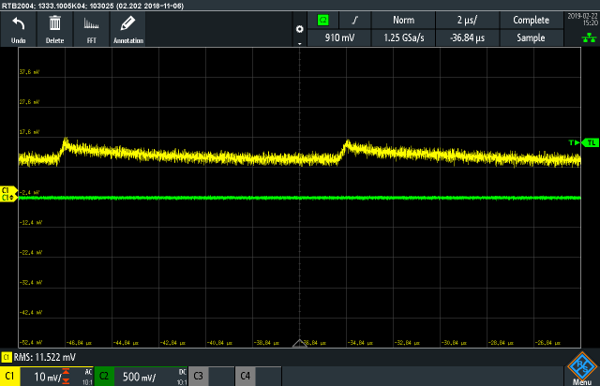

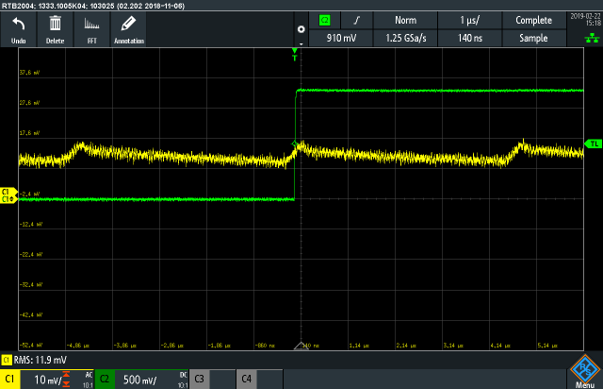

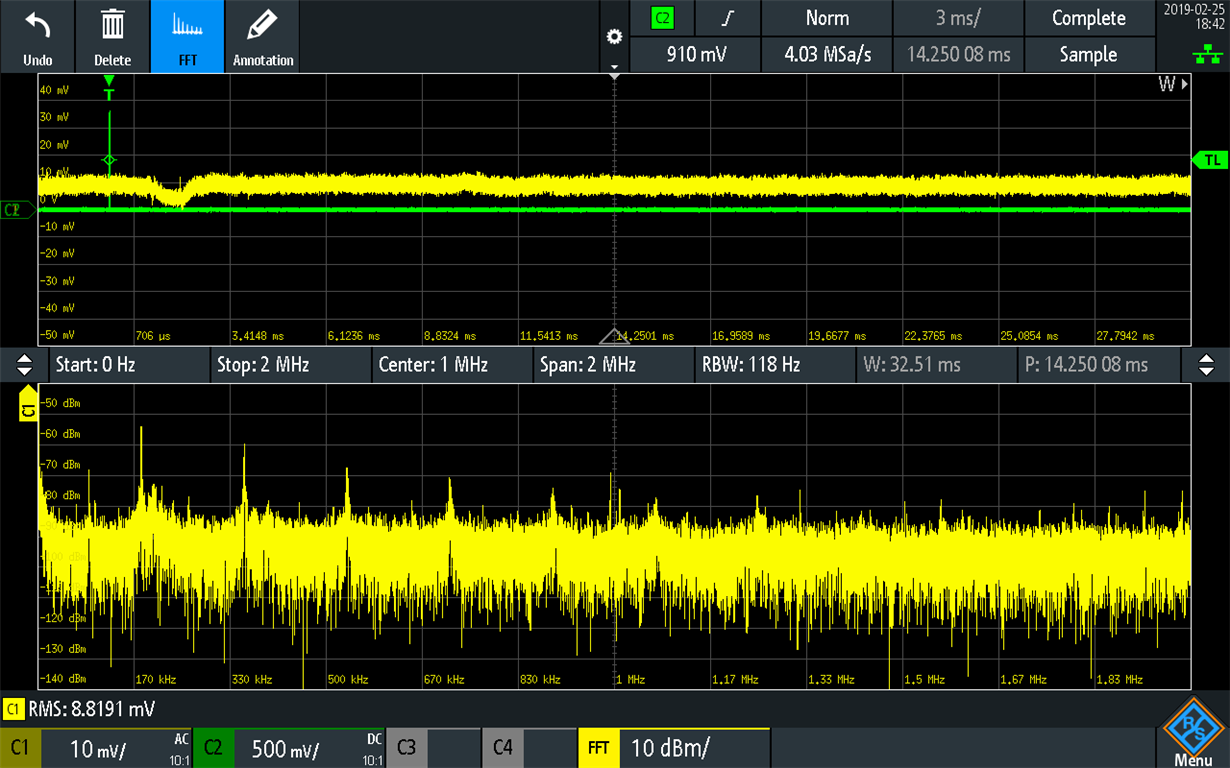

I am using the TPS62748 as a power supply in one of my designs. I am using an MCU that draws 4 mA so starting the MCU is no problem. However, from time to time I activate another component in the design which is also connected to the buck converter. This component momentarily consumes 70mA. I then see that the buck converter can't switch from PFM to PWM mode, so this component never starts.

Obviously I have done something wrong.

The output capacitor of the buck is 10uF (same as input capacitor). Total load capacitance on buck (including output capacitor): 18.7uF. I don't have a good estimation of the PCB capacitance. I have used the following inductor:

1285AS-H-2R2M=P2 from Murata.

Could you please tell me where to find more information about what parameters affects the switching from PFM to PWM mode so that I get a starting point when searching for the root cause in my design?

Thank you!