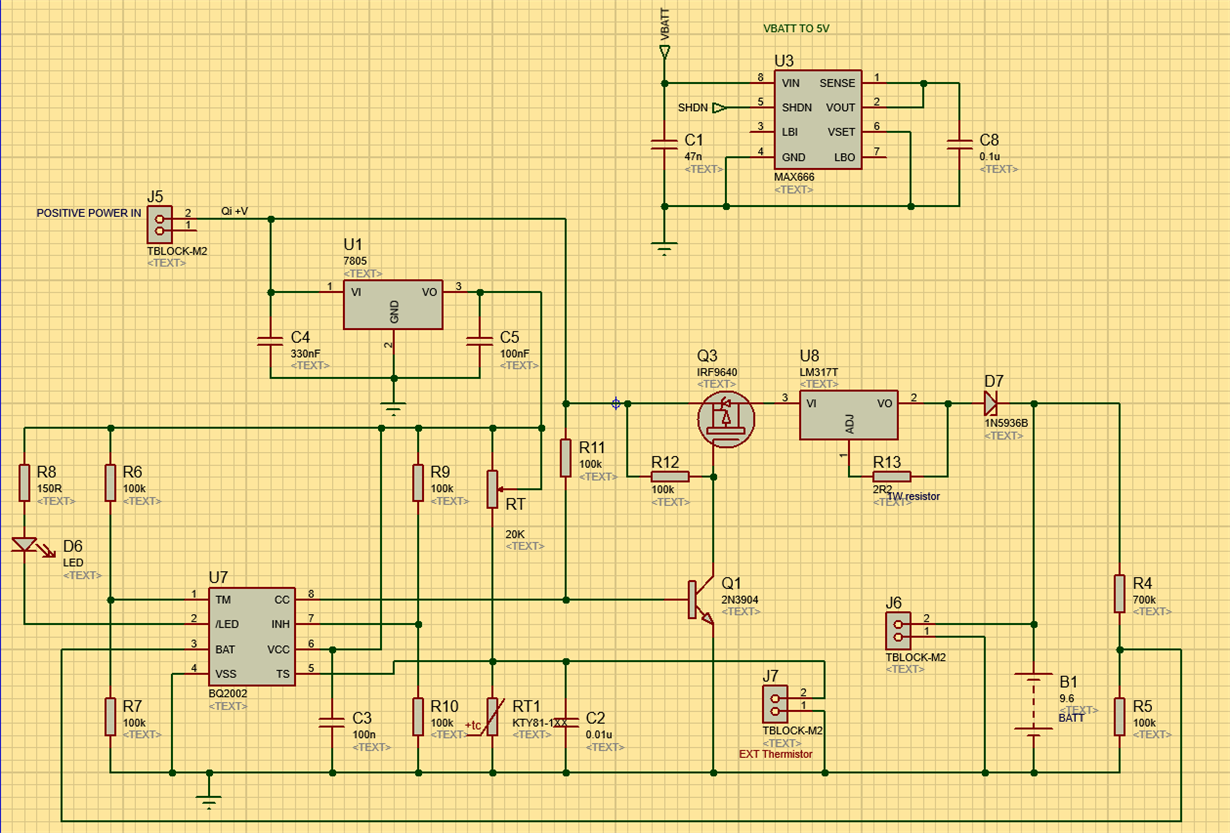

Other Parts Discussed in Thread: BQ2002

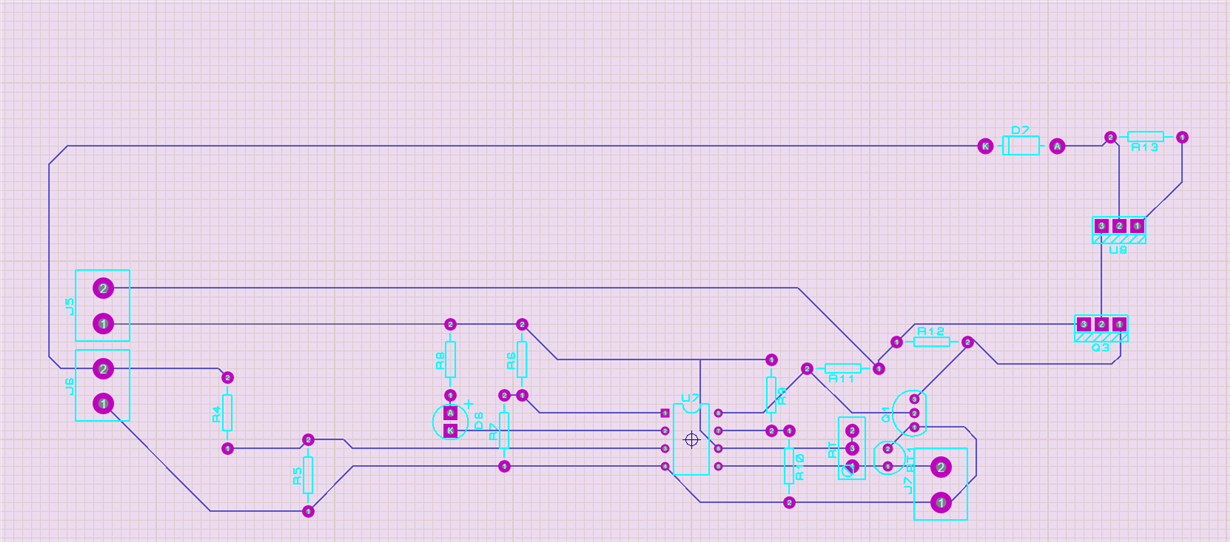

Having replicated the DV2002L2 design ( http://www.ti.com/lit/ug/sluu007b/sluu007b.pdfand verifying against the potential divider equations in the BQ2002T datasheet I find there are still issues.

It appears the LED logic and potential divider do not conform to what I expected on the datasheet.

1) /LED status seems to be reversed, high when fast charging monitoring the CC output as a reference.

2) I want to charge 8 NiMH cells so Rb1= 7Rb2; Rb1 = 100k and Rb2 = 700k.

To switch over from fast charge the voltage at pin 3 (BATT) the measured voltage was 3.6V, not 2V as per the flow diagram.

With the current configuration the battery voltage required was about 29V, not the expected region of 9.6V

The input voltage is set to 12V regulated by a 7805 for VDD. Increasing the supply voltage doesn't change this behaviour.

BATT inputs and TS are set by a 22k pot for evaluation before disconnecting and feeding battery voltage to BATT for testing.

Thanks in advance.