Hello,

I just powered on my new 230Vac board that uses TPS92075.

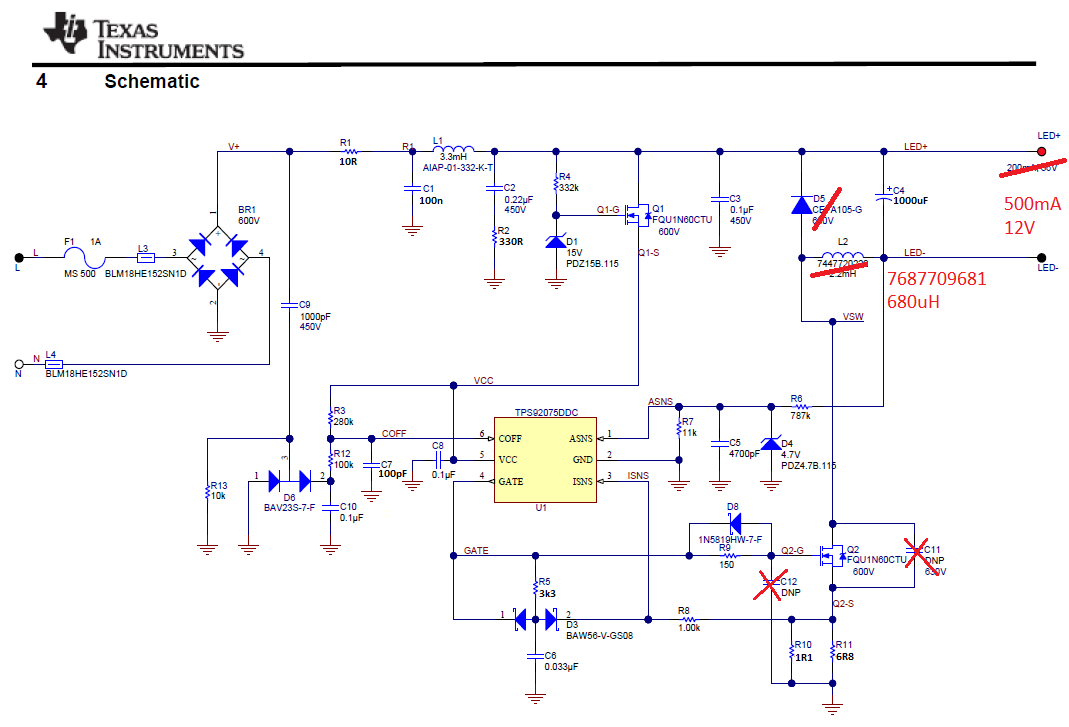

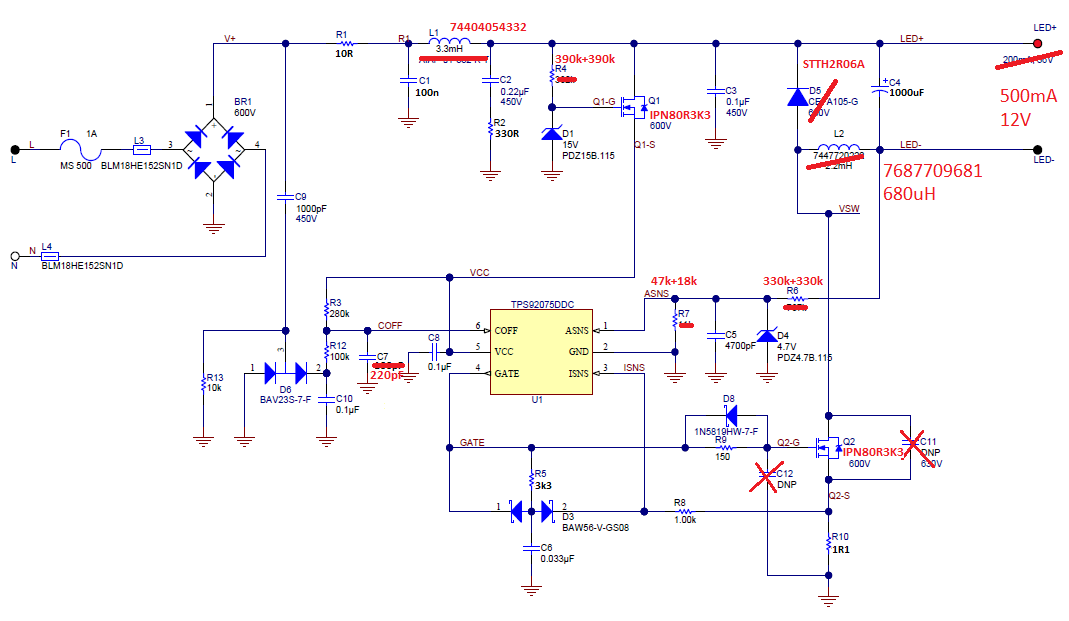

This is schematic:

On output there are 4 LED (series, 3Vx4 = 12V), Rsense is 0.95ohm to reach ~500mA

Main problem is that LED current is ~3mA (Voltage on Rsense is ~4mV)

Minor issue is that LED are turning on after 2-3 seconds

What can I check?

I don't need to dimmer it, there are some component that are controlling triac dimmer? Can I remove them?

Thank you a lot