Hi,

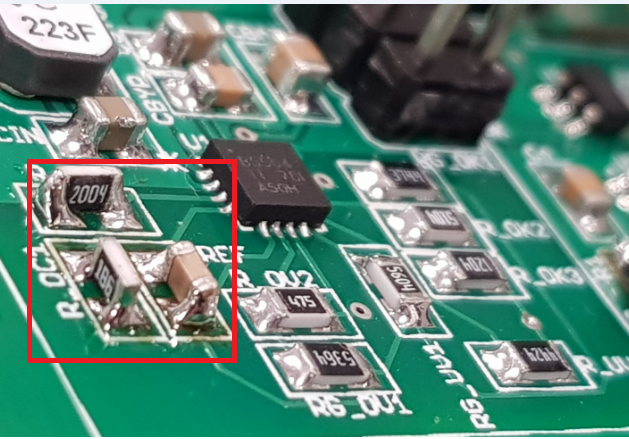

I had made custom PCB for BQ25504 and asked fabrication vendor to fabricate PCB for me.

I also make sure i followed all guidelines from the datasheet PCB layout recommendation.

BQ25504 chip i bought are from element14 "https://sg.element14.com/texas-instruments/bq25504rgtt/battery-charger-li-ion-qfn-16/dp/2144306?scope=partnumberlookahead&ost=2144306&searchref=searchlookahead&exaMfpn=true&ddkey=https%3Aen-SG%2FElement14_Singapore%2Fw%2Fsearch"

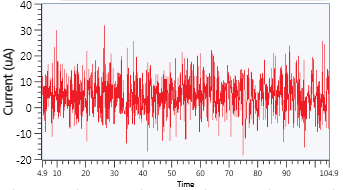

I tested my 2 PCB boards with same harvesting source and both of my boards have all same components.

My issues are as follows:

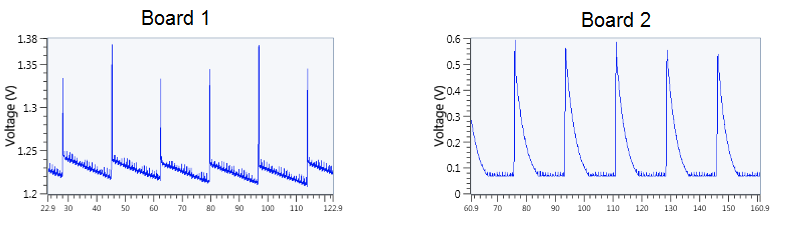

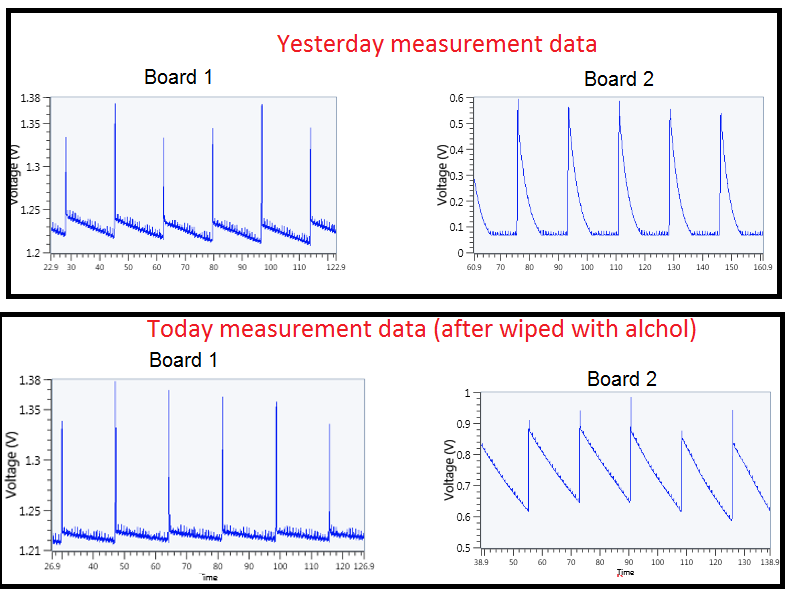

Board 1:

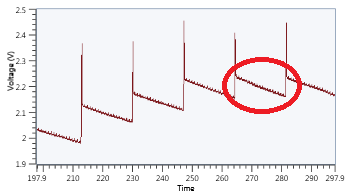

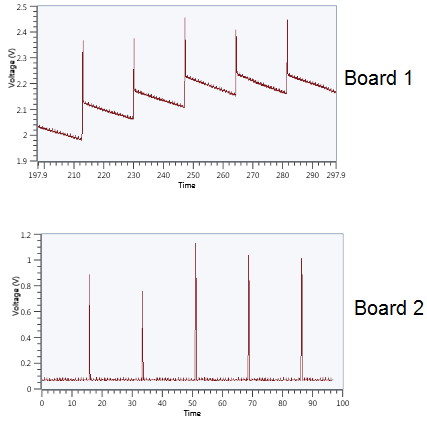

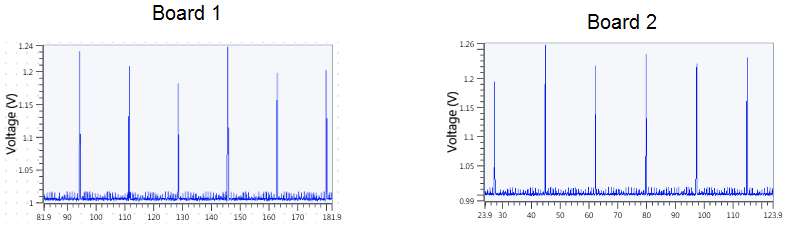

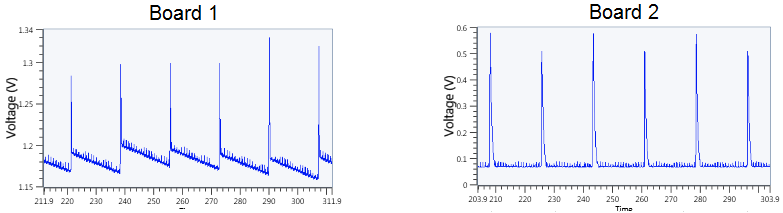

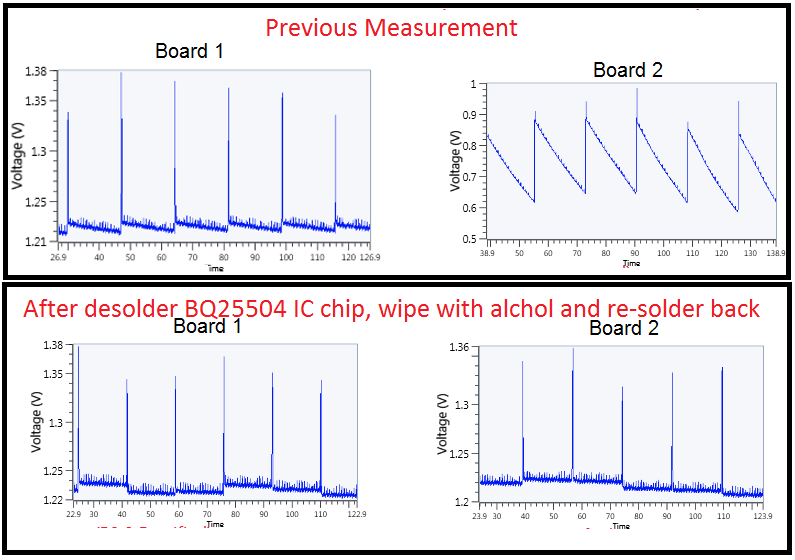

- When i measure input voltage to PM, i found out that OCV and MPPT 90% seems ok. However, after OCV sampling, input voltage keep dropping and creating saw tooth pattern. I have tested BQ25504 evaluation boards before and if i recall correctly, after OCV sampling the voltage should remain that level until next OCV sampling, right?

- So going down like that, is it a problem? What could be the possible issue?

Board 2:

- Then i test my board 2, which has the exact same components as well as same input source with board 1.

- I noticed board 2, OCV doesn't even close to 2V, whereas, board 1 OCV is ~2.4V.

- Besides OCV difference, board 2, MPPT seems to be way off too. I set it to be 90%, as like i did for board 1.

For both of the board, I make sure that during both testing, VBAT voltage is pre-charged to abotu 2.4V to avoid cold start state.

I will really appreciate if you can suggest me regarding with above mentioned issues i encounter. Thank you.

Regards,

LB