Other Parts Discussed in Thread: CSD19536KTT,

The charge pump operation is intermittent. This is related to power-up (connecting battery or bench supply to the BAT side of the circuit). Once connected and functional it appears to run with no problems. The intermittent refers to the initial connection. If I cycle power on the BAT a few time and get it to come up, it works and continues working.

Cap at VDDCP is 2.2uF/25V to provide sufficient capacity for 8ea CSD19536KTT FET's. Filter is 100ohm/.01uF. 75V Zener to protect part.

Battery operates 45-60V, testing at ~52V as described below.

I reproduce the problem as follows:

Connect BAT (with all BQ76200 signals low). Pull CPEN high, monitor VDDCP, leave all other control signals low.

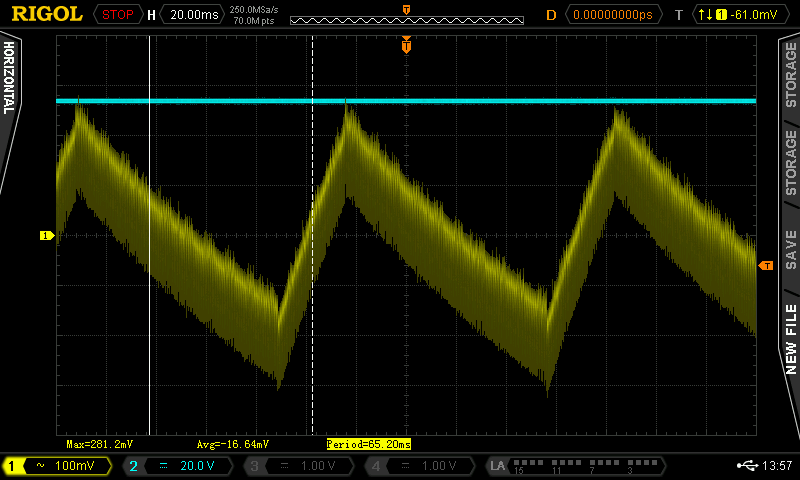

- Sometimes the charge pump generates ~1V (so VBAT + 1V). In this mode it is a steady 1V, no charge pump waveform. Enabling CHG or DCHG makes no difference.

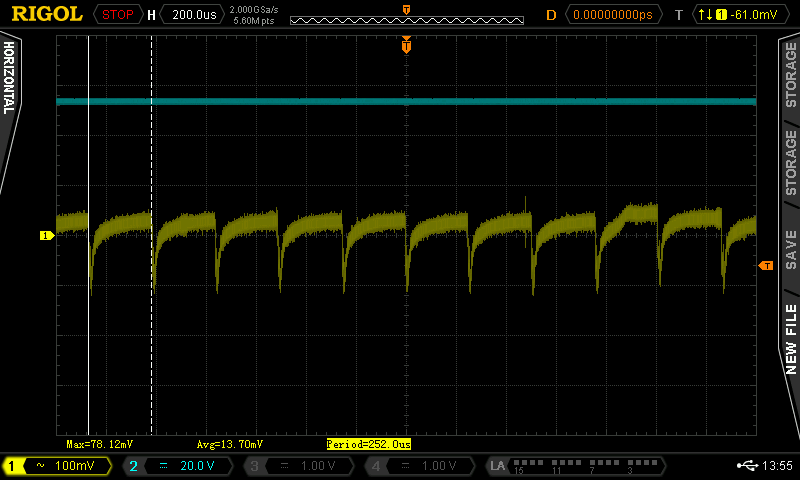

- Sometimes the charge pump generates 10V (so VBAT + 10V). In this mode the charge pump sawtooth waveform rides on top of the 10V. Enabling CHG or DCHG works as expected (FET gates rise ~10V above VBAT).BQ76200 Circuit.docx

I'm attaching a word doc with the schematic snippets (hope it shows).