Other Parts Discussed in Thread: LMR14030,

Hi Ti team,

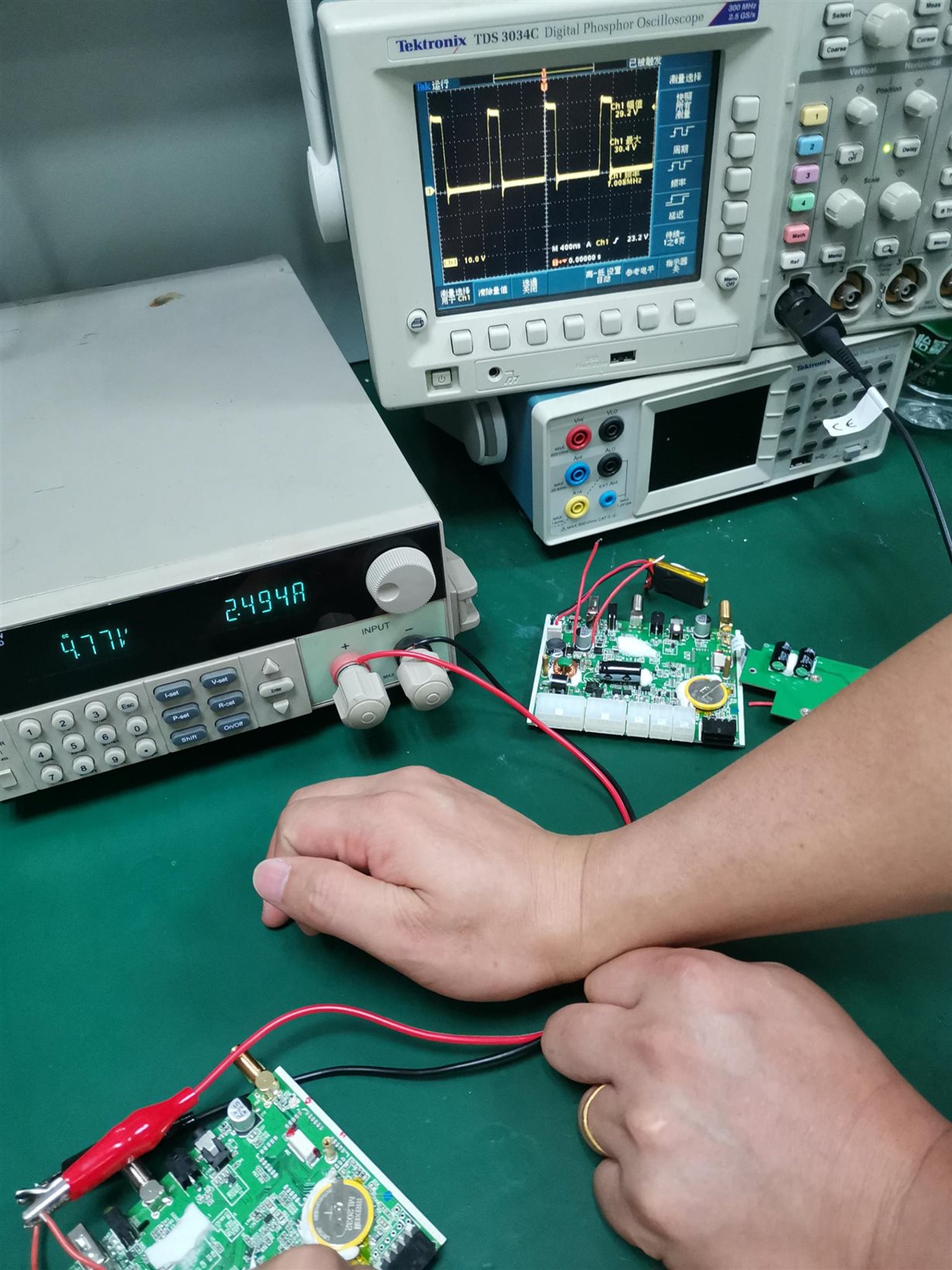

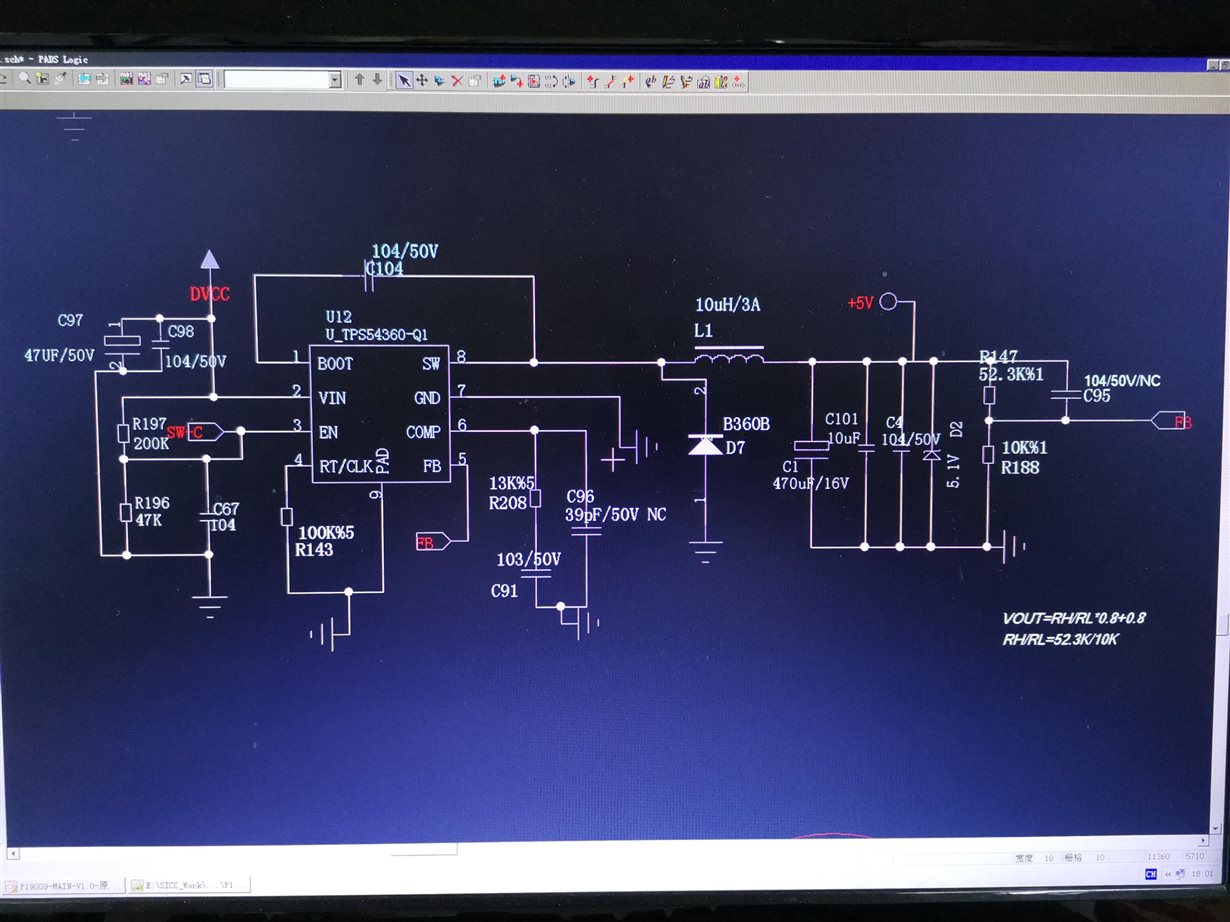

1. Phenomenon: TPS54360 is burnt out in the aging process(Vin=30V,Vout=5V/0.2A-2A) and abnormal impedance was found in Vin, Sw or EN pin

The Vin pin in particular has burned off. About 5pcs out of 100pcs were burnt out

2. Check and test found two problems:

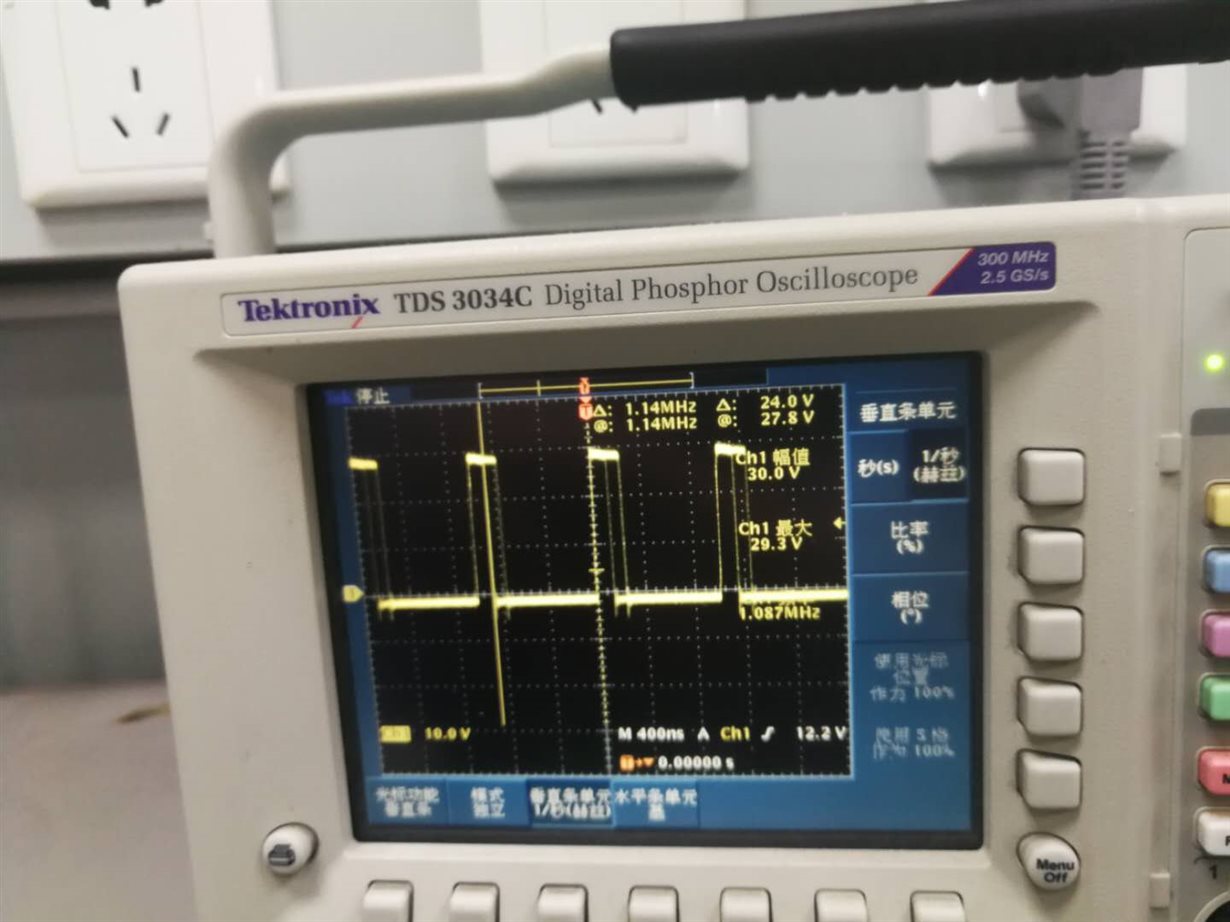

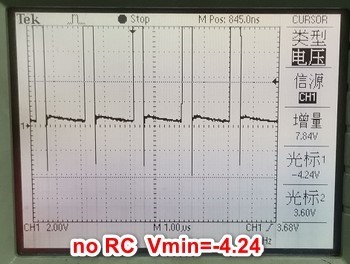

A, IC BucK circuit is not stable, and the waveform of Sw foot is different in size (as shown below)

B. Input 30V start up, Vout 5V/ 1.5a or above current test start up waveform, Vout overshoot up to 8.3v

3. Rectification results:

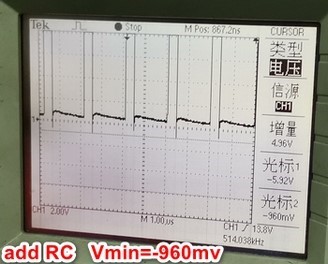

A, FB feedback the capacitance in parallel on the pull-up resistor, C95 0.1uf is removed, and the problem of abnormal waveform of SW foot is improved( test waveform as below)

B. The working frequency of the switch is changed from 1Mhz to about 700K, which improves the overshooting problem of output voltage

4, After modification, Producted 100PCS for aging experiments(Vin=30V,Vout=5V/0.2A-2A), and now another one is found burnt out, the phenomenon is the same as before

5,Please help to confirm whether there may be other problems causing such burning?

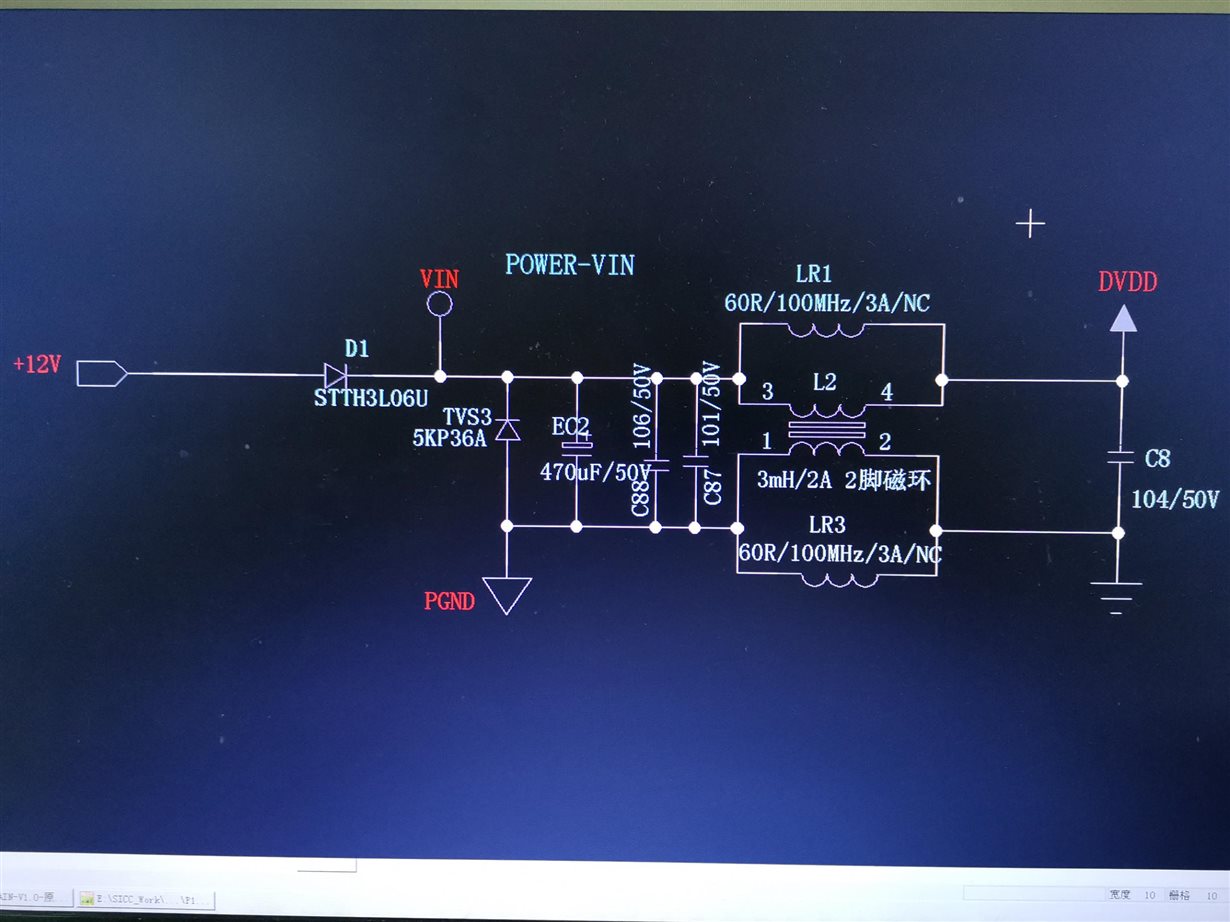

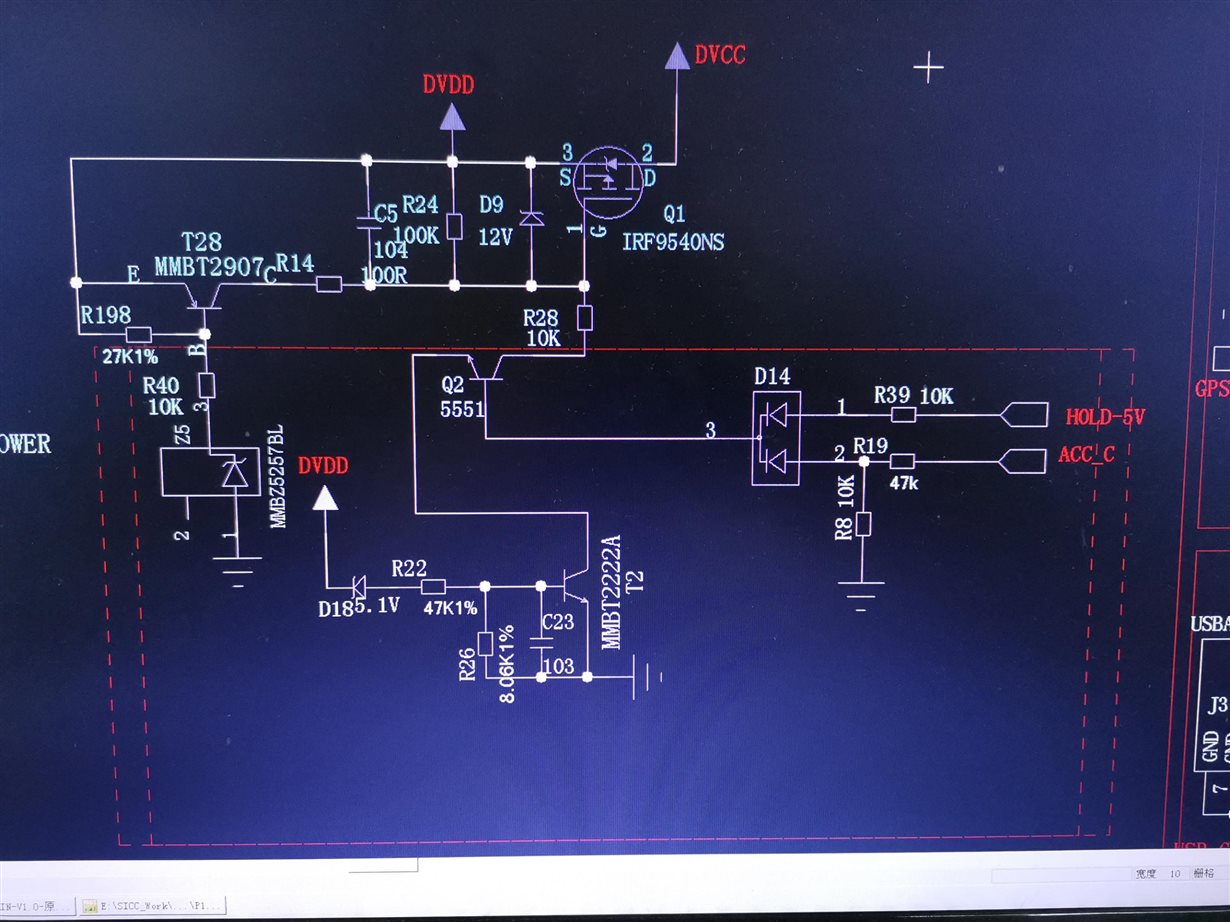

6, SCH as below