Other Parts Discussed in Thread: TPS63802, TPS61089, TPS61022, TPS61088

Here are my design parameters using a TPS63070:

Vin = 2.0V - 3.2V

Vout = 6.2V

Iout = 1000mA

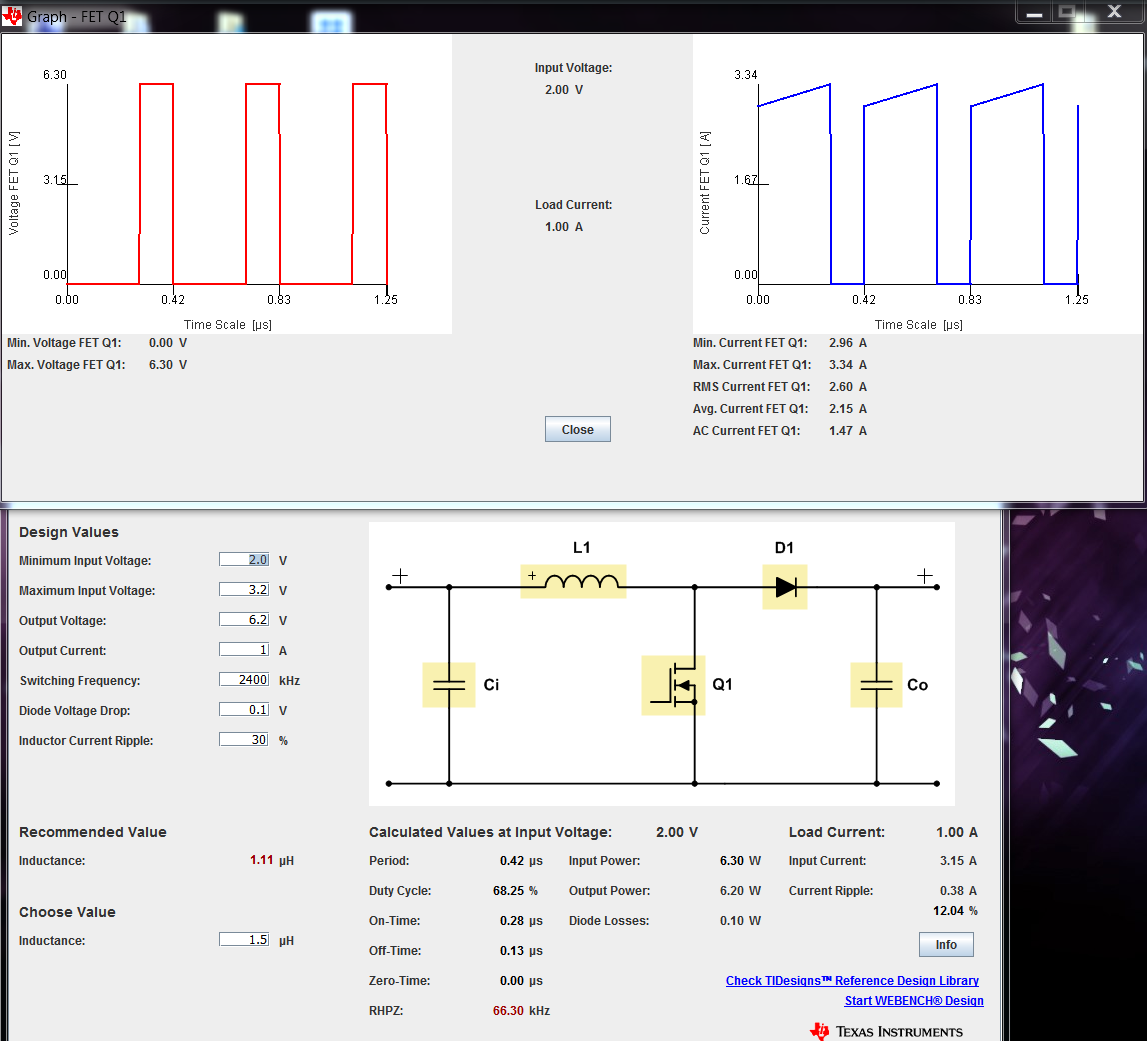

Assuming 80% efficiency in boost mode, duty cycle D = 1 - [Vin,min x efficiency]/Vout = 1 - [2.0x0.8]/6.2 = 74.2%

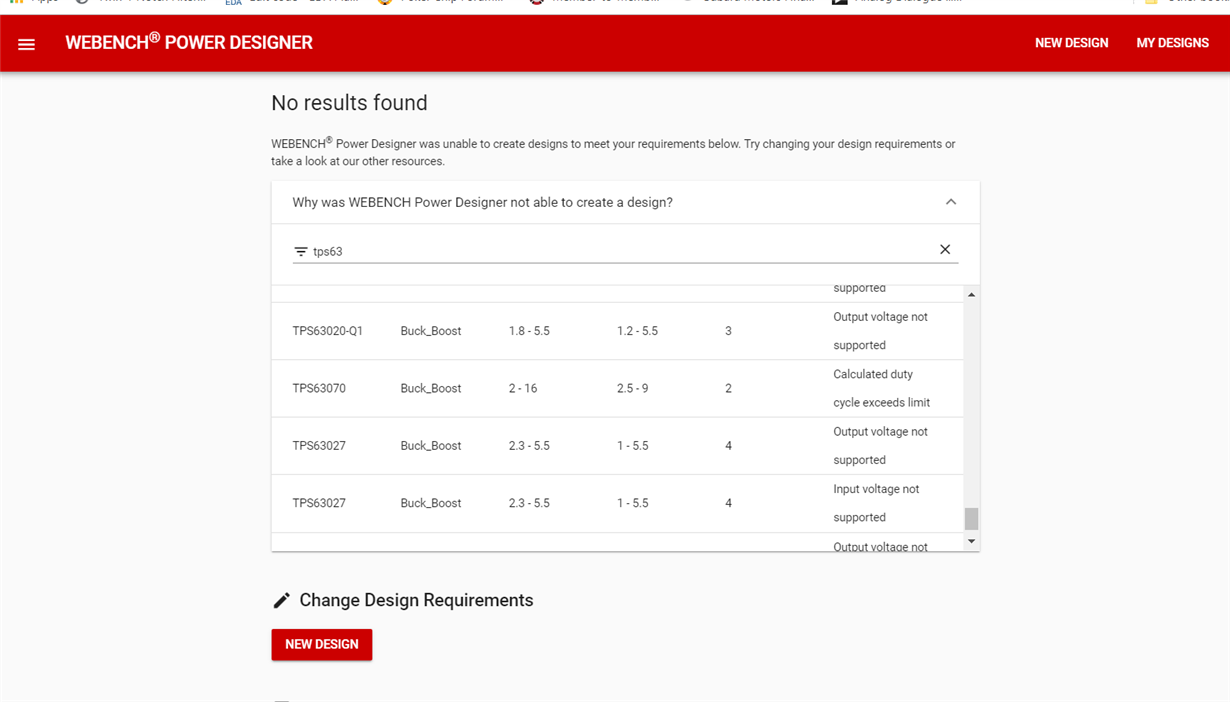

When I plug in the above numbers into WEBench, the online tool reports back that a design cannot be made due to "max duty cycle". However, the TPS63070 does not have a max duty cycle specified in the data sheet; so, this leaves me to wonder (a) Why is no max duty cycle specified in the data sheet? (b) Is it really the max duty cycle that is limiting this design?

Also, when I run the numbers for switch current inside TI Power Stage Designer, I find that the switch current stays below the 3.6A limit:

Hand calculations more or less match the above results +/- a few percent.

I'm confused. It feels like I am missing something here because one set of tools and hand calculations are saying the design is possible with this PMIC, but WE Bench tells another story. What is the true reason the TPS63070 cannot handle the above conditions?