Hello,

I am using UCC2803 for a dual-output active-clamp flyback converter switching at 1MHz. The input range is 7 V to 28 V and the output is 24 V. Everything was fine except for the startup performance.

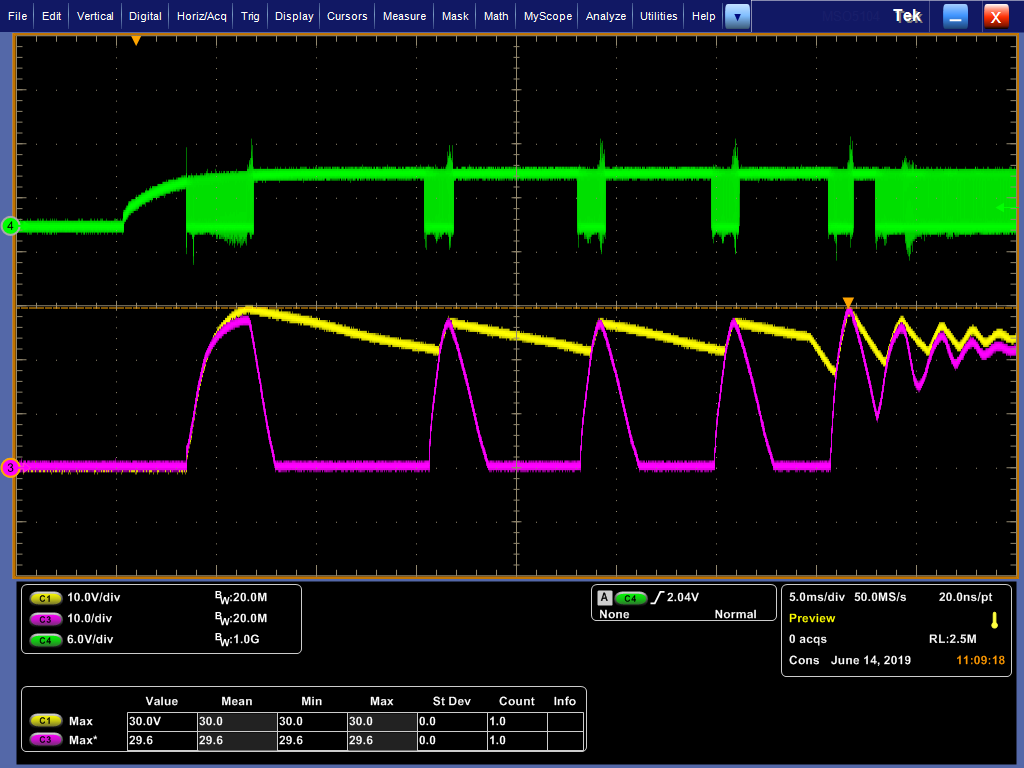

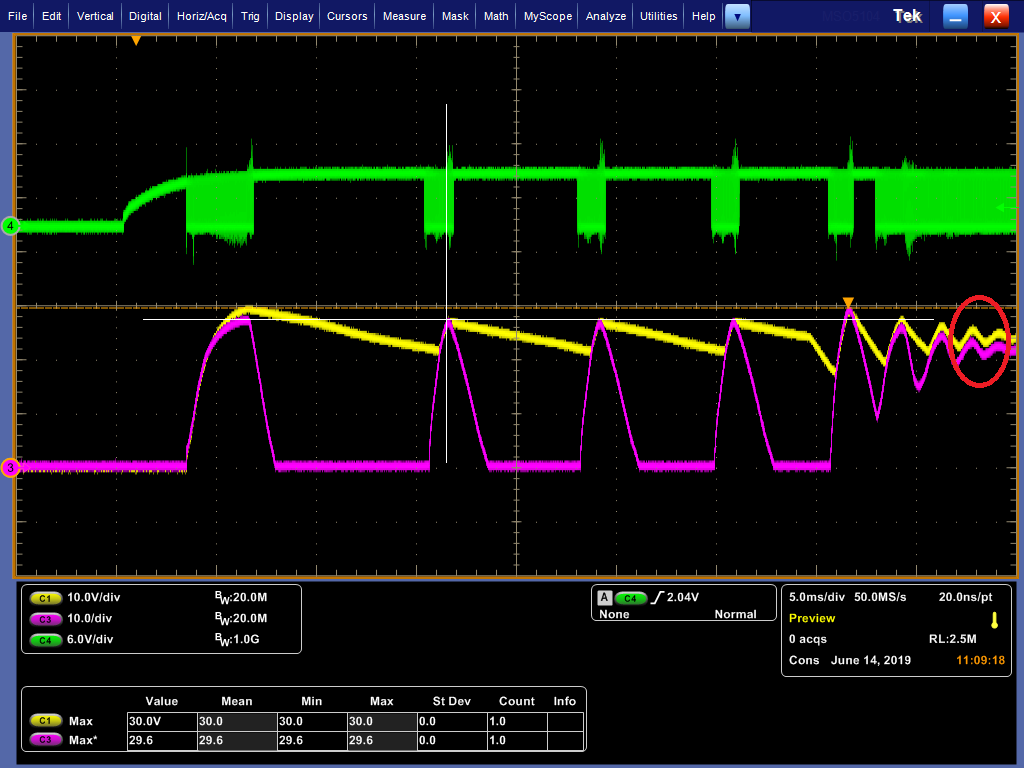

Please see the experimental waveforms during the startup as following. The green waveform is the inverted PWM output while the yellow and pink waveforms are the two outputs of the active-clamp flyback converter. You can tell from the waveforms that the converter successfully entered the steady state in the beginning, however, the PWM output was turned off and turned as the over-current protection was triggered. It repeated several times and this happened randomly. To solve this problem, I reduced the sensing resistor significantly so that the sensed current will be much smaller. It did improve this performance but it could not solve this issue.

It doesn't make sense to me as it happened after the converter has entered the steady state. Normally the current spike should be smaller than that during the start up and why the faults were only triggered in this period instead of the start up. So I am wondering if TI engineers know what happened and what cause this problem. What can I do to control this.

Thanks,

Jiewen