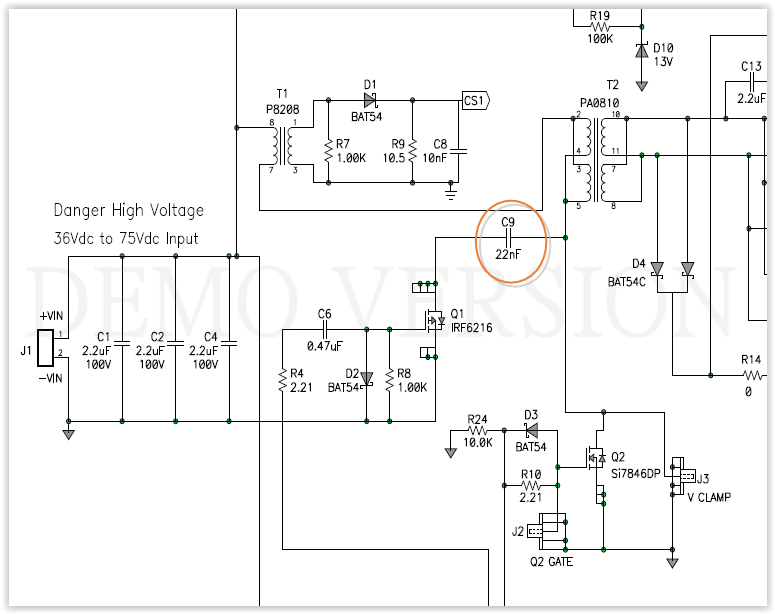

I know that the design tool has calculated C9 (CCL in the design tool), but I am worried that if we design Dmax=0.8, according to the Dmax deviation of the datasheet, the maximum duty may be as high as 0.88, press f=250KHz, toff=0.12*4us= 0.48us, plus delay time 0.1us, Q1 turn-on time and turn-off time are 0.05us each, the reset time is only 0.28us, in such a short time, how can the voltage on C9 be enough to make the transformer magnetic reset.

What I want to know is the design related to the magnetic reset of the transformer, not only the transformer design, but also the selection of the clamp capacitor C9.