Hello,

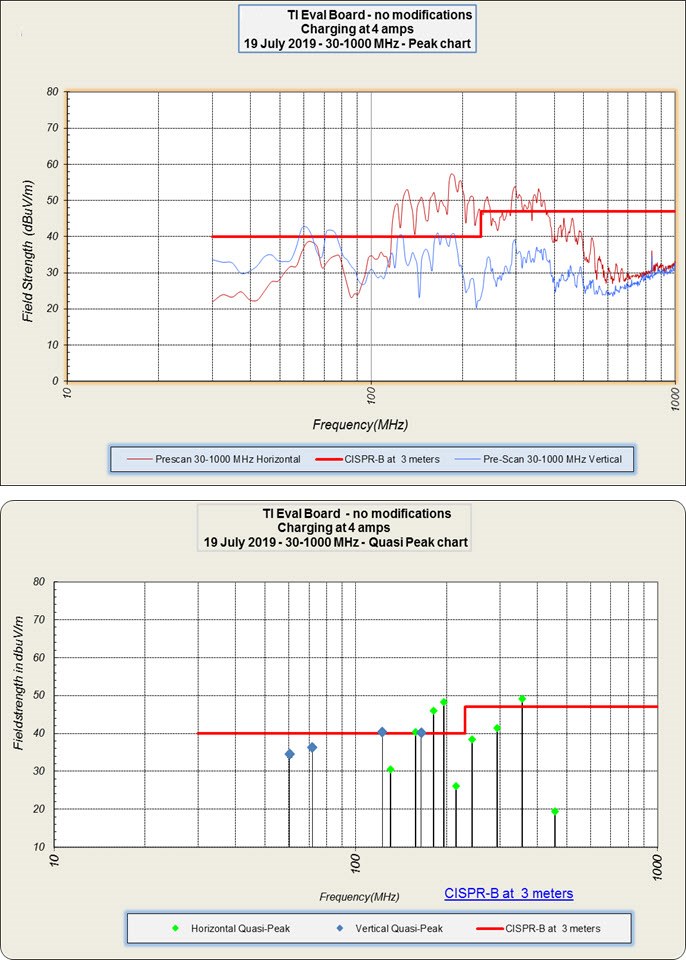

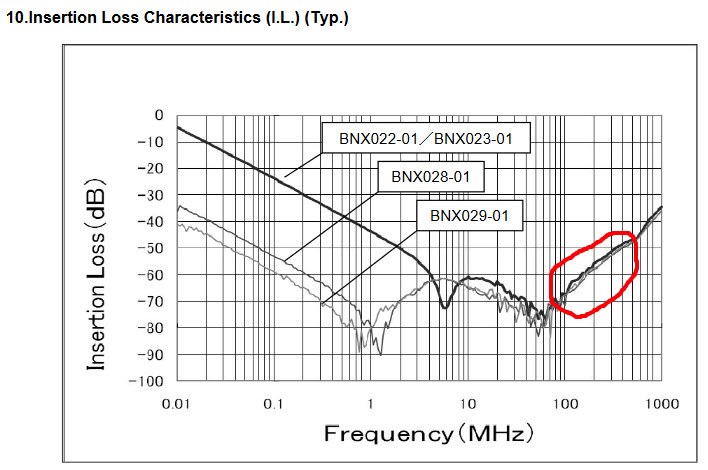

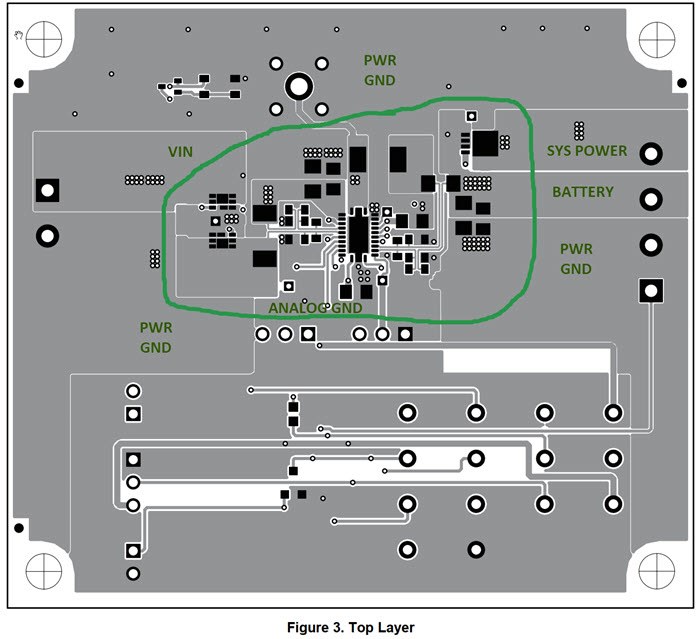

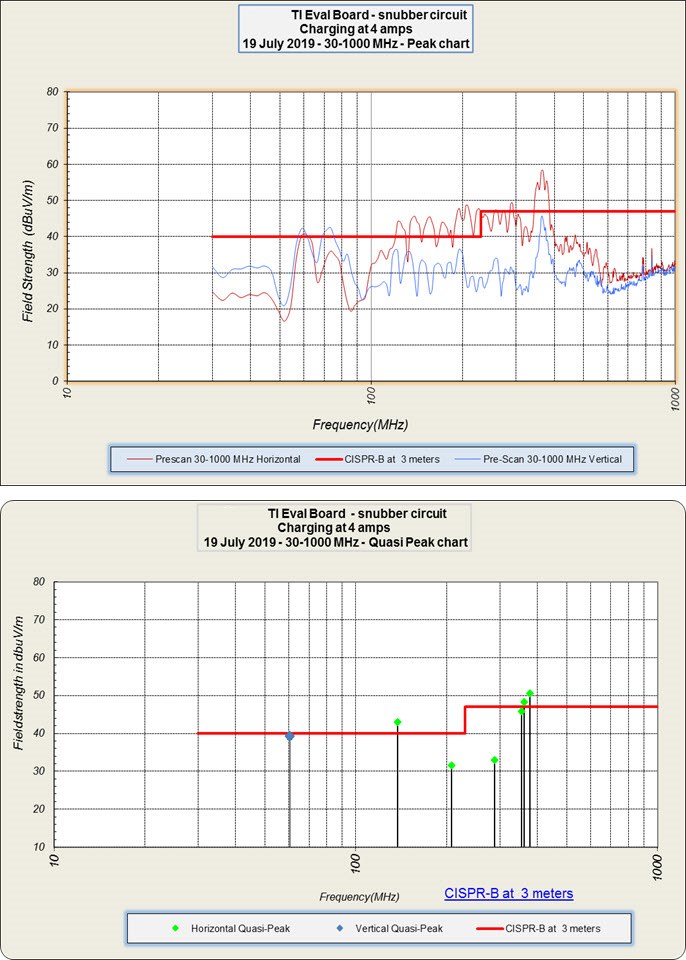

I have a customer whose design uses the BQ24170 and when enabled is caused EMC issues. When comparing the EMC test resuts to those of the EVM by itself you can see they both fail in the same frequencies with the dominate fail at the Fsw ~1.6MHz. The EVM has places for BTST and snubber but we are looking for guidance on what values to use in TI EVM to reduce the radiation so that a similar solution can be used on the customer design. Please advise.

Tony