Hi everbody,

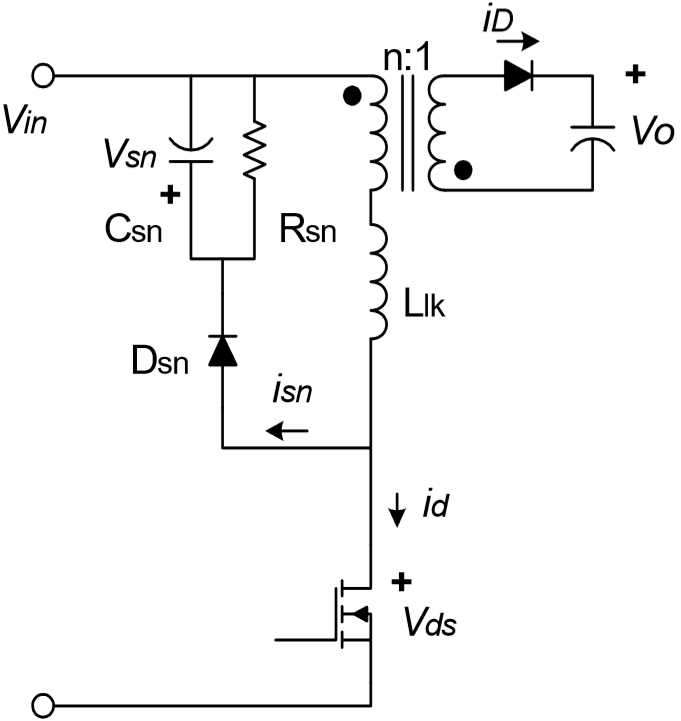

I'm designing an RCD clamp snubber circuit for a flyback converter to absorb the current in the leakage inductance when the drain voltage exceeds the clamp capacitor voltage. Finally, this will prevent switch overvoltage.

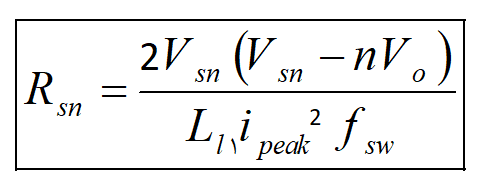

OK, the most important matter is to measure the leakage in order to be able to calculate the snubber resistor value from the equation below.

schematic of the converter+snubber circuit

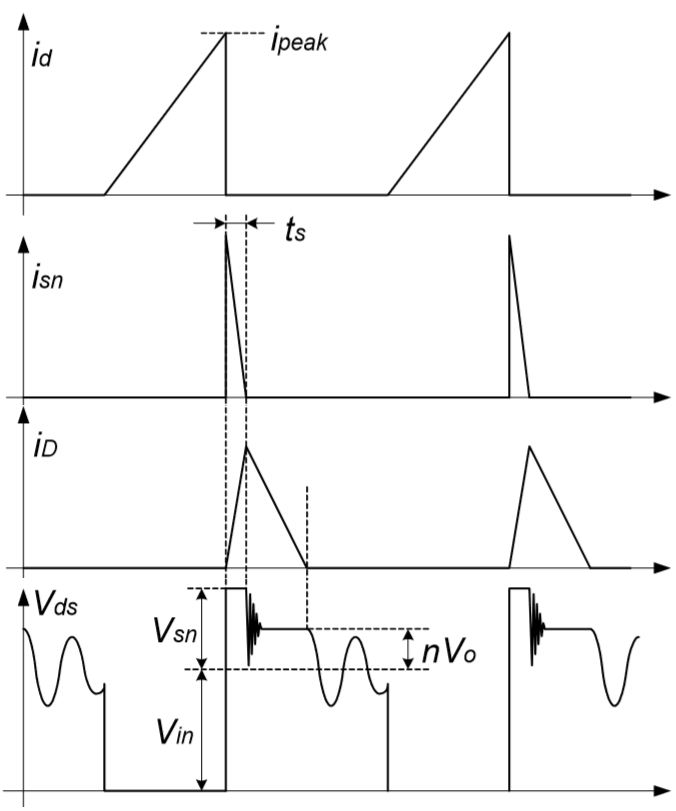

and the waveforms are shown below

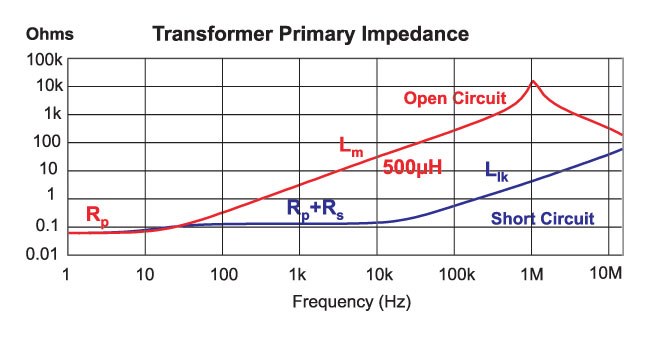

There are different techniques to find and measure the leakage inductance. One is to use two-stage measurement:

- Open circuit test (the secondary winding is open circuit, and the LRC meter measures the {primary inductance (Lp)+primary leakage inductance(L1l)} )

- Shorted-circuit test (the secondary winding is shorted, so the LRC meter only measures the primary leakage inductance (L1l)

But, the technical problem is that the wire we use to short circuit the secondary winding has its own impedance (resistance+inductance). Therefore the inductance which is measured in test2 (short circuit test) consists of the primary leakage inductance+N^2*short circuit wire's inductance. For more details, please take a look at this link.

Considering this issue (the wire used to short circuit the secondary winding is not ideal and has inductance which affects on the value of inductance measured in the short circuit test as mentioned above), does anybody have any practical technique to measure the primary leakage inductance?

I myself want to use a frequency response analyzer to solve this issue. Because I think the inductance of the short circuit wire changes less in comparison with leakage inductance in different frequencies and this leads to calculating only the leakage inductance as shown in the image below (linear region of the blue curve)

I would appreciate if anyone has had a similar issue and has tried a similar technique (using a frequency analyzer to measure the leakage inductance) to solve it.

Regards

Hossein