Hi

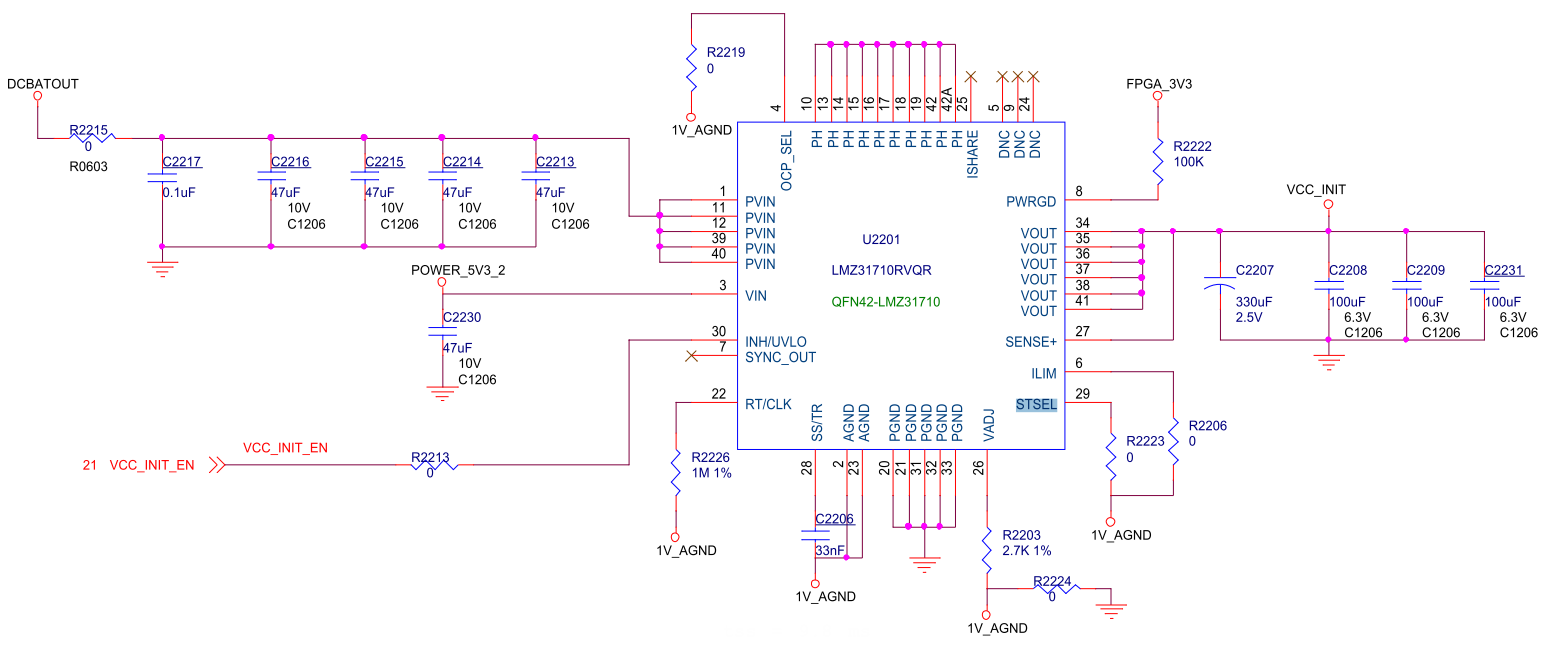

We have 10~20% failure rate after SMT.

Could you help to review schematic as attached? (DCBATOUT:4V, VCC_INIT:1V)

Besides, do you have recommend stencil pattern for this part?

Besides, do you have recommend stencil pattern for this part?

If we bought this chip on the market (not from agent) , could we send it back to you for further failure analysis after cross verification?

BR,

CY