Other Parts Discussed in Thread: BQ24040, BQ51221, BQ51021, BQ51020, BQ51013B, BQ51010B

Dear Support

I am working on a design that requires Qi & NFC

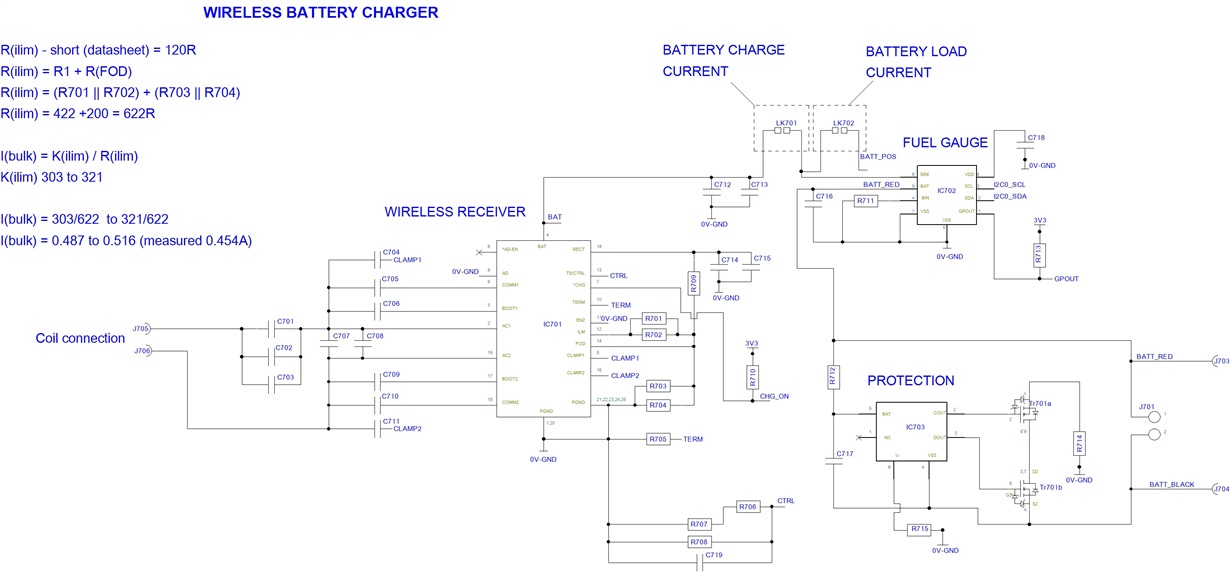

I have used BQ51050B IC to implement Qi Receiver circuit.

I have used the dual coil from Wurth:

https://katalog.we-online.com/pbs/datasheet/760308103307.pdf

One of this coils is used for Qi Rx

2nd Coil is used as NFC antenna

I measured the Ls & Ls' of coil and calculated the respective Capacitor values

So far,

the Qi receiver side works "fine" as in the Battery (1200mAh) gets charged BUT as long as the the Coil sits flat and flush with the surface of Qi charger (Although the fast current measured (as measured by Fuel Gauge IC BQ27421 = 0.454A instead of expected 0.487A to 0.516A)

If I add a 2mm thick plastic (I used a sleeve from Mobile phone cover) in between the Charger surface & my Receiver coil then the Charging does not start. ( In actual application the circuitry would need sitting inside a mechanical enclosure but as it is 3D printed at the moment and I was not sure about the precise thickness of material so I used a plastic sleeve from Mobile phone protection cover)

** Coil sits flat on the plastic sleeve as well (so it is not sitting at any inclined angle)

(I measured Ls' with that 2mm gap)

My 1st question:

How do I fix this distance problem as I was expecting Qi Rx to work even when coil is 2mm to 3mm away from the Charging Base surface?

So far, the whole design is based on theoretical calculations (formulae form datasheet) for the two Resonant caps values that I have fitted. I have not used any other calibration methods

I understand (from one of the videos on TI training section) that in order to work our Qi Rx with any Qi transmitter, it needs to be FOD calibrated. and the method involves purchasing

AVID Technologies QI FOD transmitter & use it with FOD calibration tool from TI

& searching it online it seems to be out of stock with lead-time of 8 months.

My 2nd Question:

Are there any other recommended cost effective methods available to perform the FOD calibration? As AVID module is on 8 months lead time. Do Qi Rx designers using TI's BQ51050B have any other option to do this calibration?

Now, regarding the Dual coil,

The NFC coil (metal) would always be exposed to Qi Transmitter (Charger). We would be using either NFC or Qi at a given time. But,

My 3rd question:

Could Qi Charger Transmission (energy) be picked by NFC coil & consequently could it damage the NFC related circuitry on my board?

I am happy to share the Full schematics & layout of the product and more details about the product if you could share the technical support team's email here.

Looking forward to hearing from you,

Kind Regards

NS