Other Parts Discussed in Thread: TPS61253A, TPS61022, BQ24073

Hello,

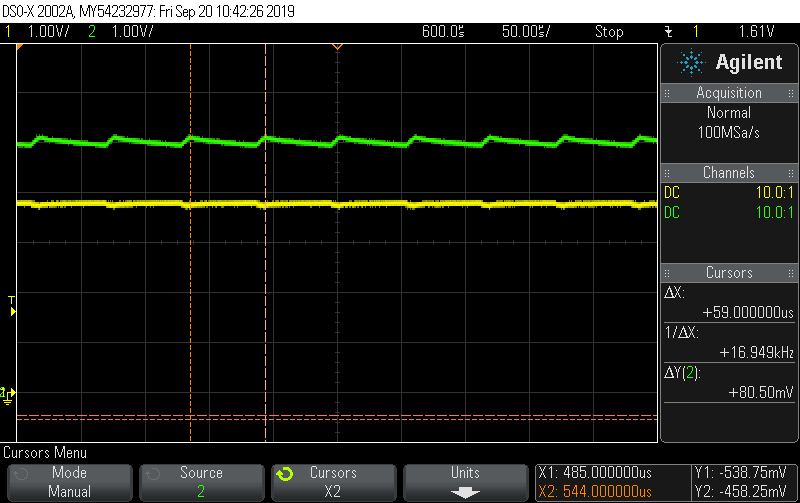

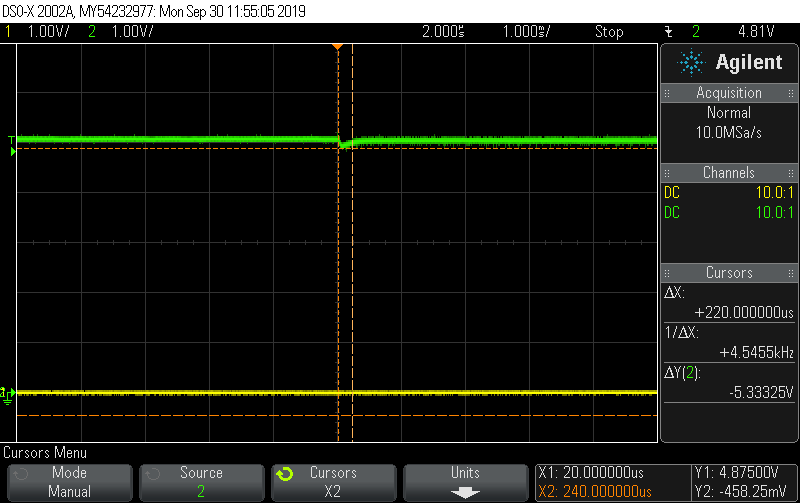

I read the related post https://e2e.ti.com/support/power-management/f/196/t/757404 and I too have this issue with audible noise. I measured the voltage at the input and the output of the boost and saw ripple at around 16-19 KHz under light loads (approximately 30-60mA). Below graph yellow is Vin and green is Vout. Vin and Vout are with respect to the TPS61236P labels.

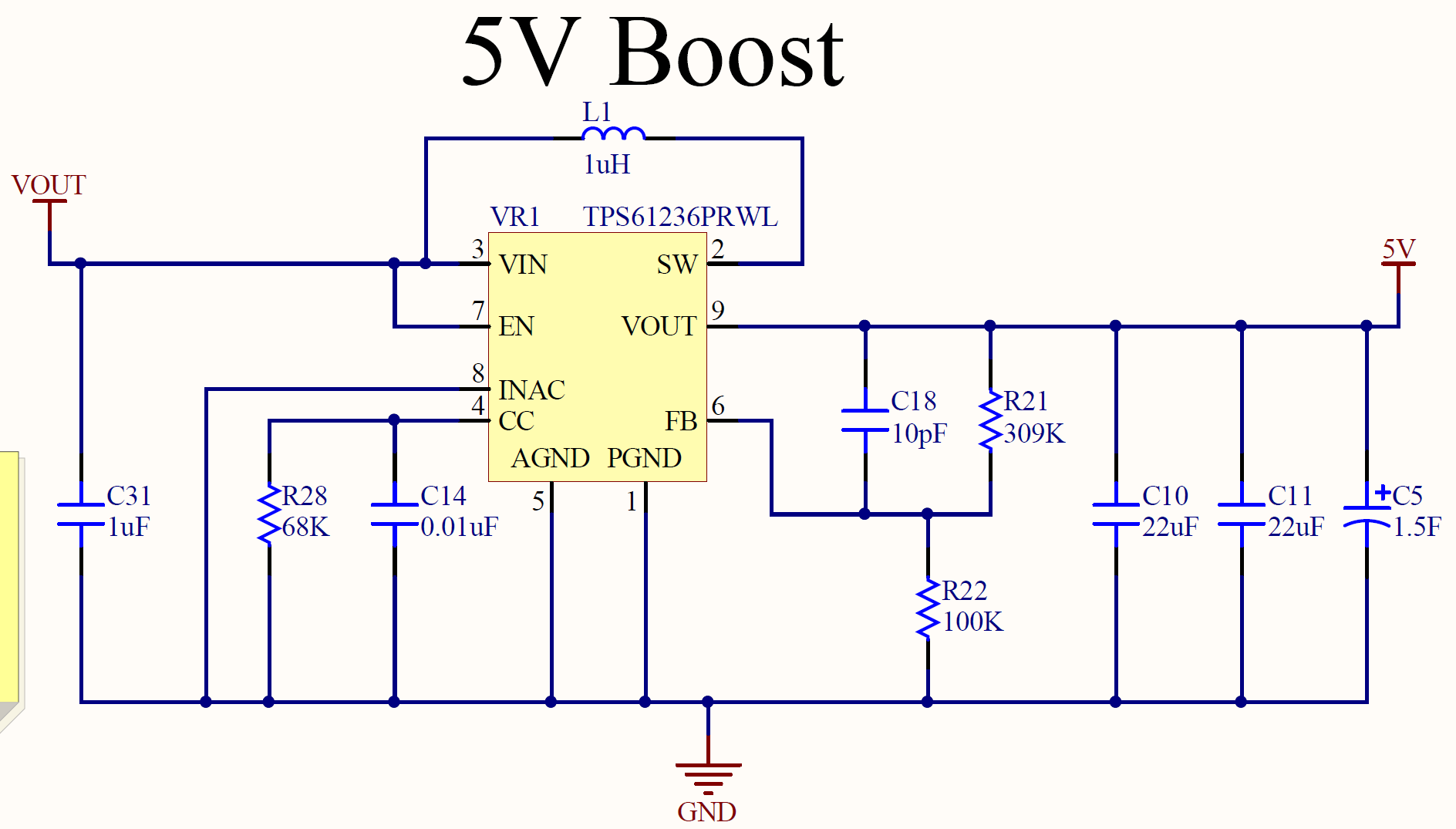

Here is my schematic as well.

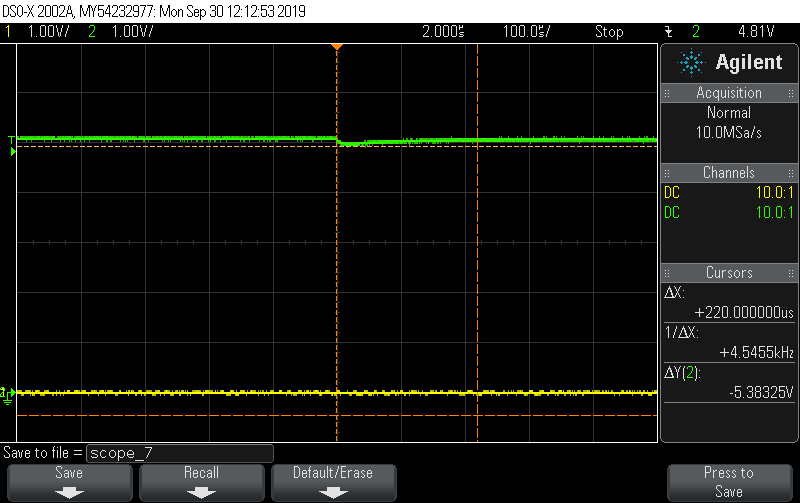

I know under light loads, the boost should enter the PFM mode. The waveform on Vout matches that given in Figure 20 of the datasheet (i cannot make out the time division info on the plot). Is it normal for this boost to operate in the audible frequency range (20Hz to 20KHz)? Are there modifications I can make to avoid this range or to at least reduce the noise?

Notes:

1. I have tested with the 1.5F capacitor off and on the board.

2. I have added extra capacity (150uF) MLCC on the input.

3. The tantalum on the evaluation board does not change the audible noises.

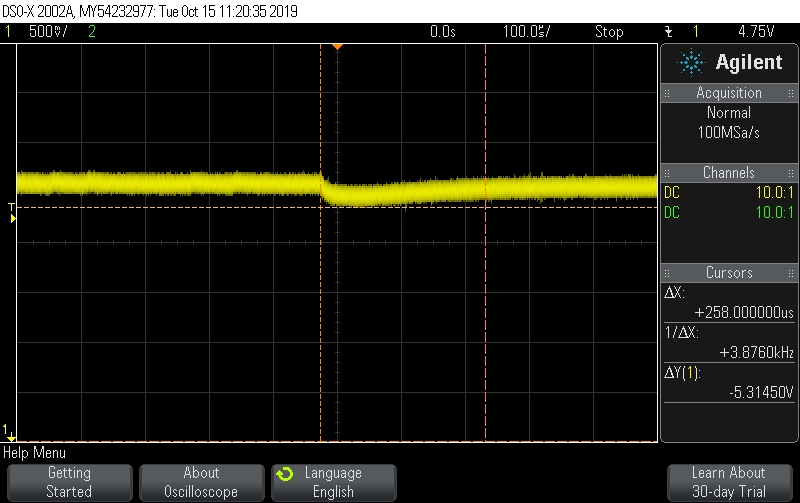

4. The board makes a much louder noise during initial boot up with the 1.5F capacitor. (In this state, the super capacitor pulls Vout lower than Vin which turns off the boost. When Vin is lower than Vout it starts again. This continues until the capacitor is charged)

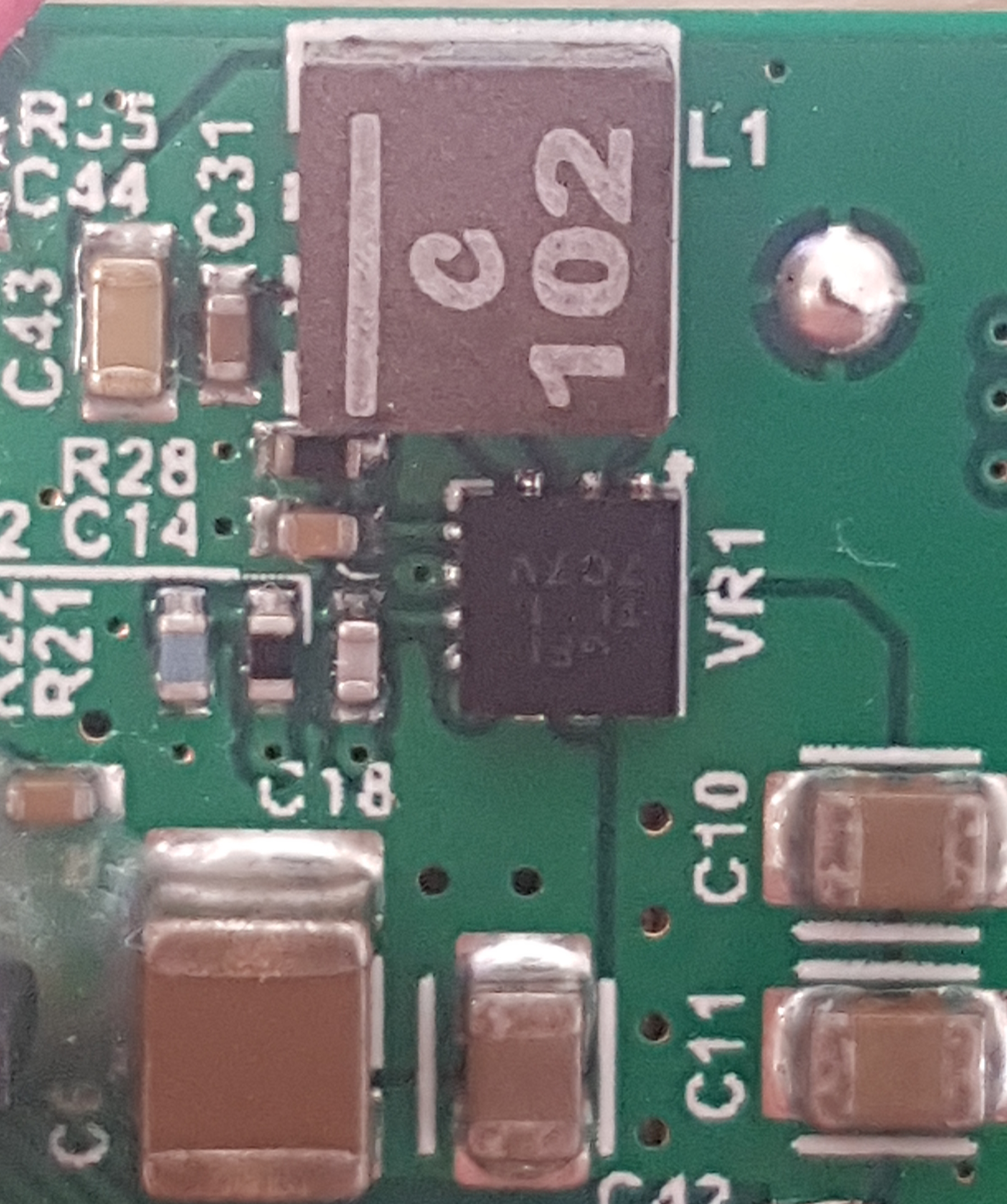

Here is a picture of the board layout