Hi,

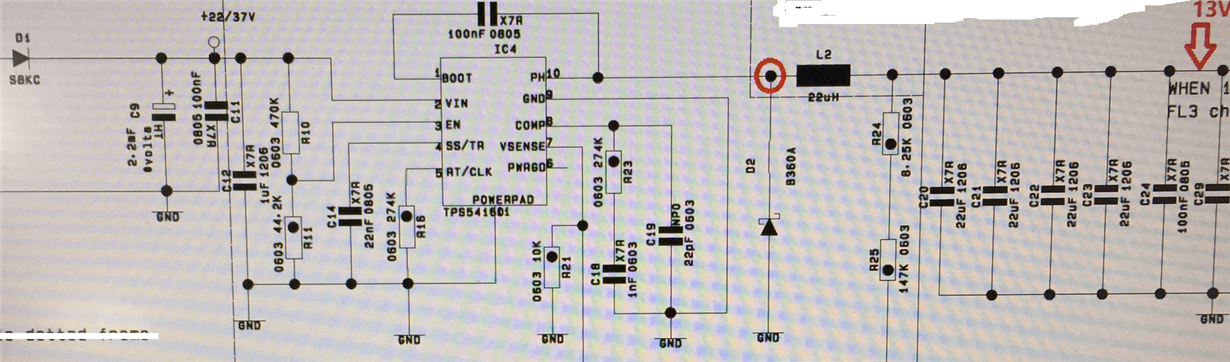

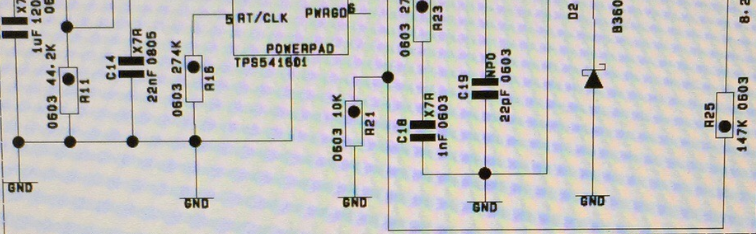

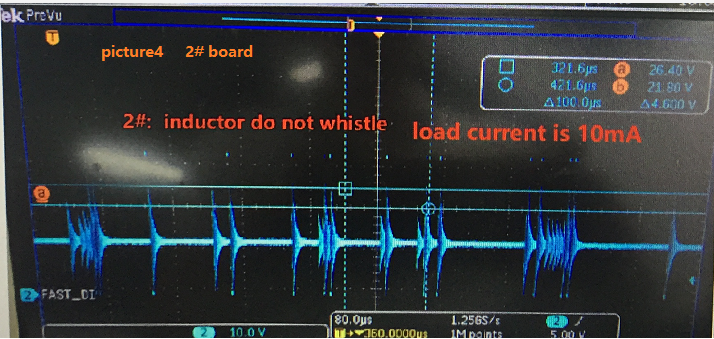

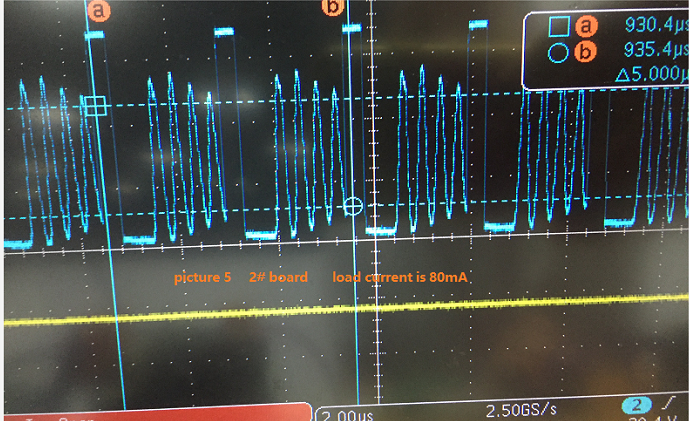

I used TPS54160A for 24VDC to 13VDC buck circuit(2# board). as the picture1 shows.load current is very small,about 1--10mA

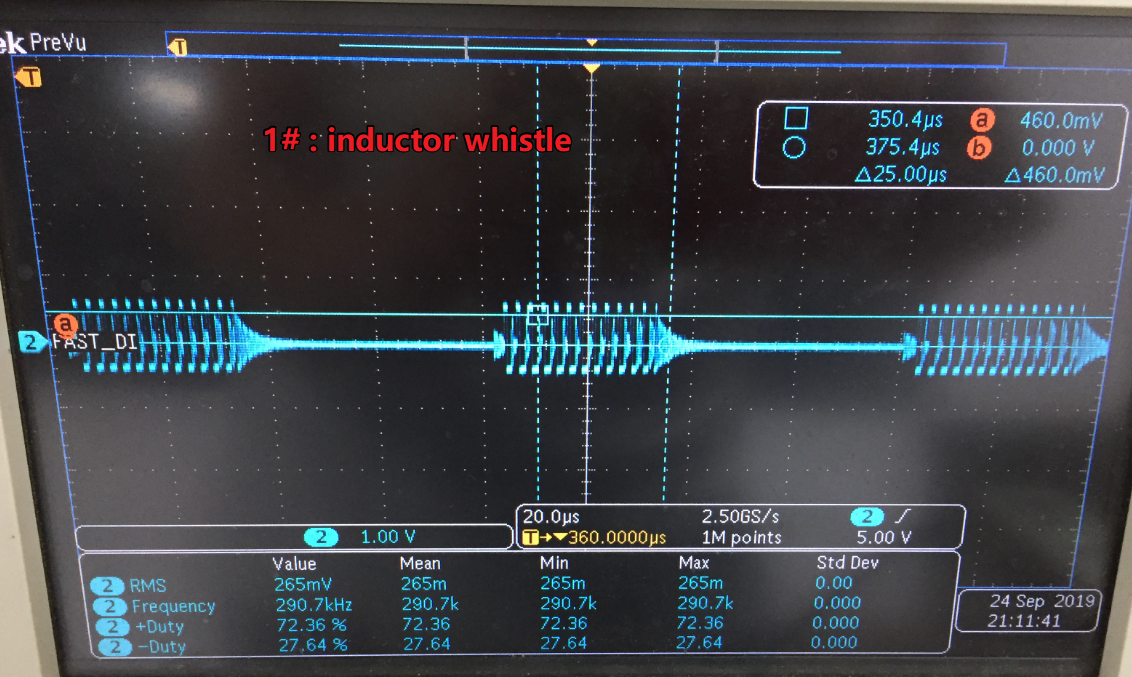

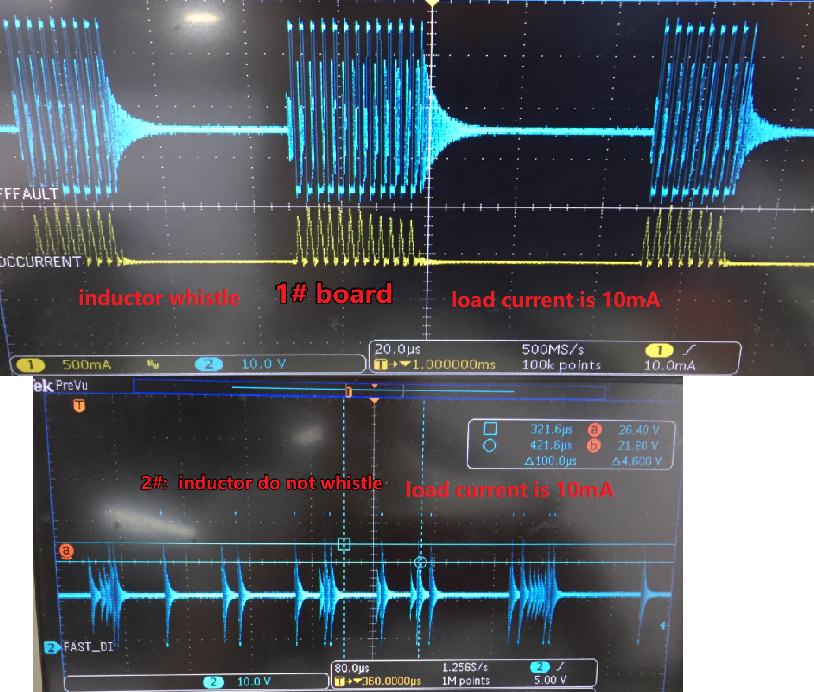

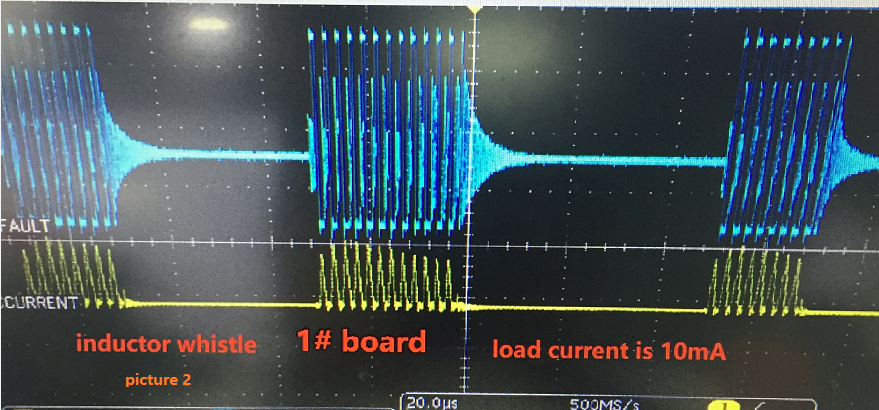

Now inductor is very whistle,but i do not know why inductor whistle and how to solve issue

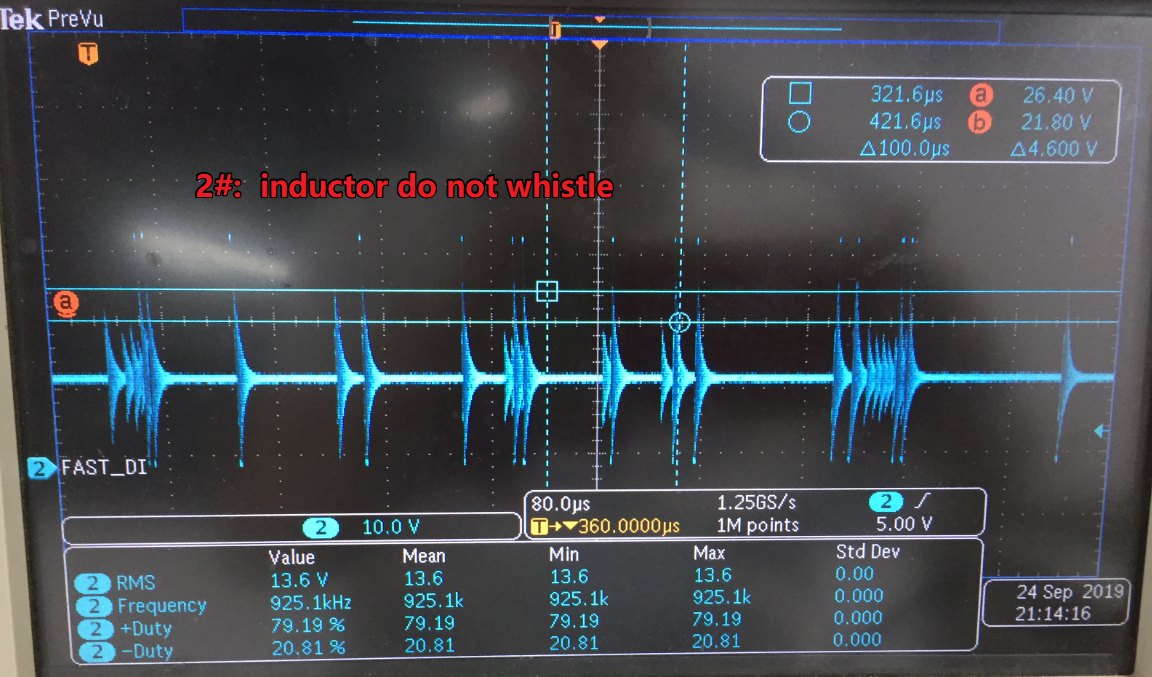

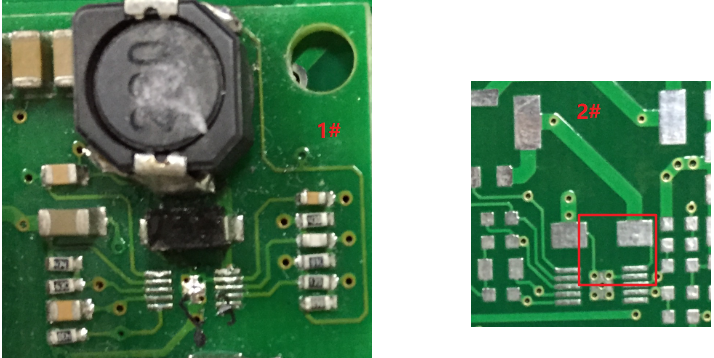

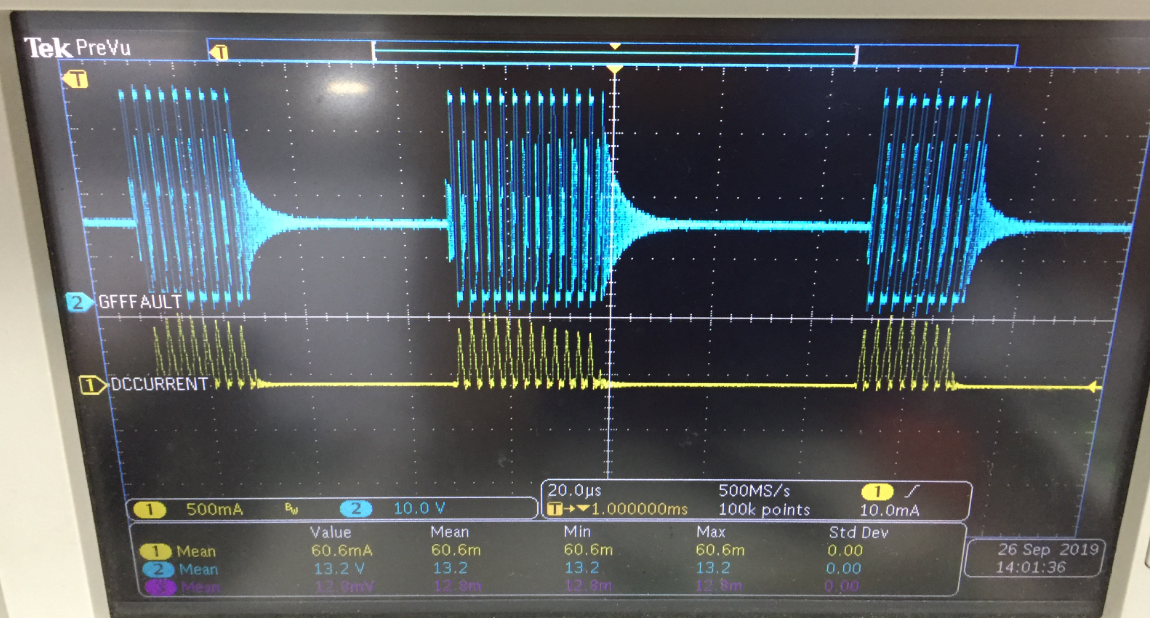

We used TPS54160A to do the same buck circuit(24VDC to 13VDC), see picture4(1# board)but inductor is not whistle,it is very good,

I really want to know why inductor whistle on 2# board,and inductor is not whistle on 1# board?

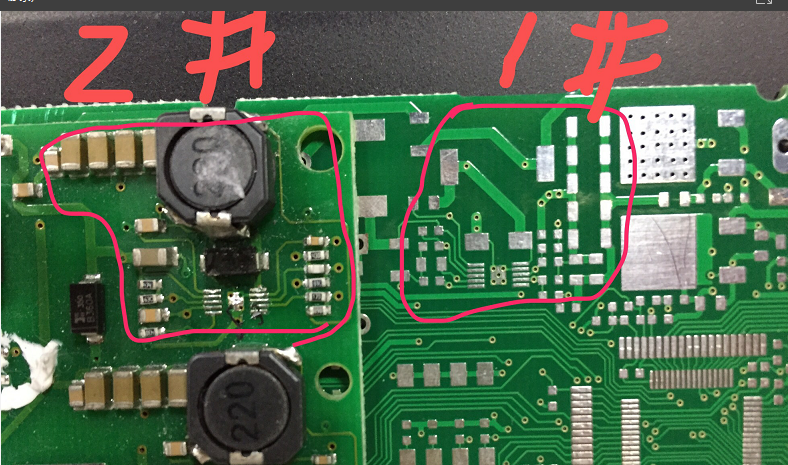

What I don’t understand is that buck circuit on 2# board is as the same as buck circuit on 1# board,and all components are the same

I only found two different points.

one point:regarding to the test waveform on red circle,the difference between 1# board and 2# board is very big. I believe that you can find the answer from this point.

other point:pcb layout have a little different,trace width in red box of 2# board is too small.

Thanks a lot!