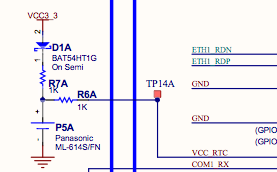

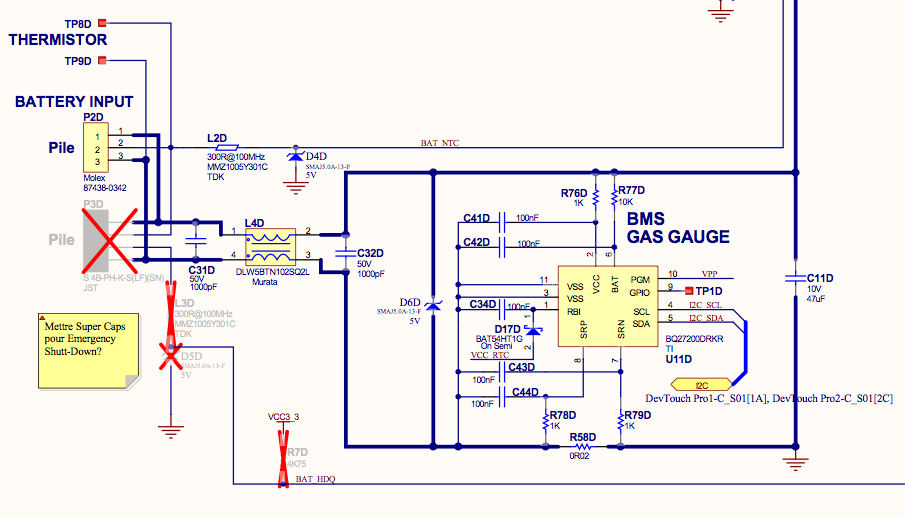

I am using the BQ27200DRKR (SINGLE CELL Li-Ion AND Li-Pol BATTERY GAS GAUGE IC FOR PORTABLE APPLICATIONS) in my design. For technical reasons, we could not put this device into our main Li-Pol battery cell. When the main battery is too low, it cuts-off thus removing power to this device which then loses its Coulomb counter value. When we recharge the main battery, the device is powered again but it has lost the main battery remaining capacity ! Is there a way I could use the 3V backup battery I have in this design to allow us to maintain the Coulomb counter value when the main battery cuts-off ?

Thanks in advance.

Pierre Richard