Hi,

I need to work on AC-DC power supply Design for an industrial Tool. it would be complete ANALOG Power Supply.

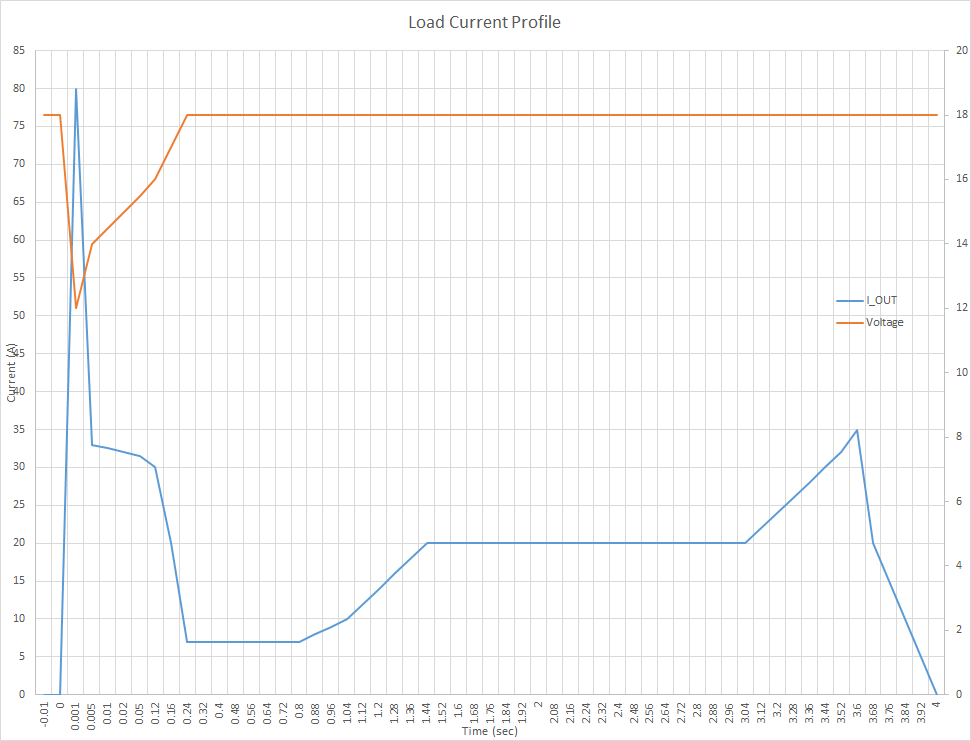

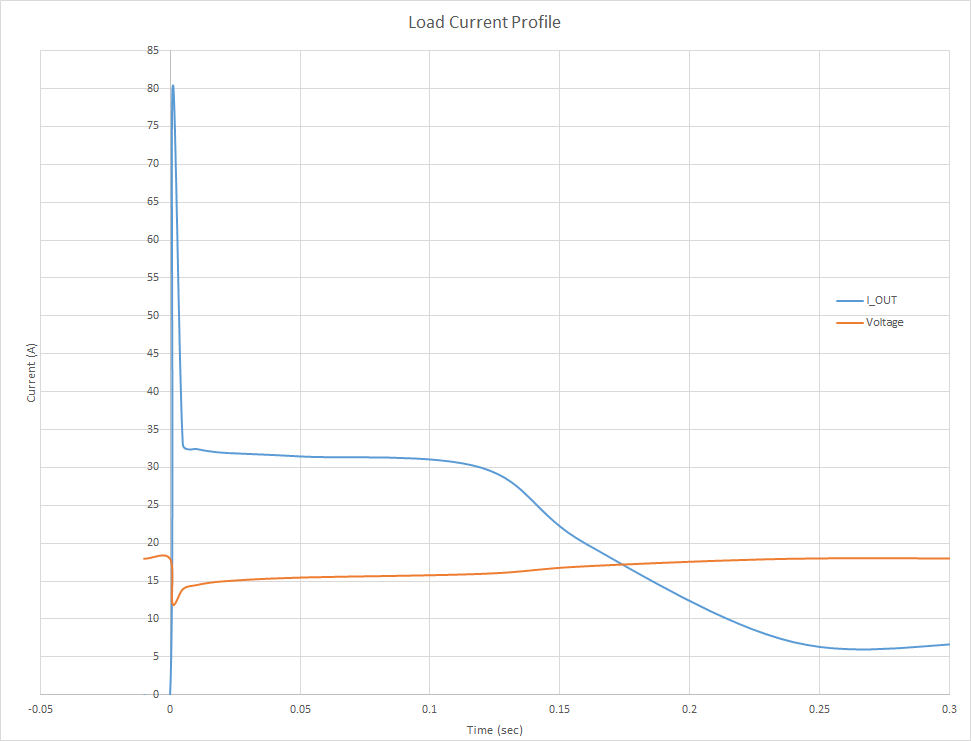

Attached is the load profile that Power supply must support.

Requirements:

1. Need to have Compact Design , No FAN or any ventilation. Heat generated has to be distributed inside only

2. NO Front End PFC, due to size limitations.

3. 205 VAC - 265 VAC (50Hz +/- 3Hz) input Range.

if load profile is observed, it is not a constant power output, but it requires peak power and required power level varies at every time.

I had though of using Half Bridge LLC topology(due to reduced switching losses), but this constant change in power level will vary the Switching frequency continuously, might not result into good efficiency. (need more information)

Load is going to be Motor, so i do not want to use synchronous rectification and since need to strive for Compact and cost effective design hence i am not going for PSFB as well. (more semiconductors, extra inductor, Costly Controller IC)

My first though considering all above points is to use 2 Switch Forward Converter as it requires minimum hardware for implementation, but i am not certain for LLC as well.

Need suggestions/ opinions regarding the topology that can give better efficiency while driving this type of load.

Thanks