Other Parts Discussed in Thread: CSD18534Q5A

Dear sir/madame,

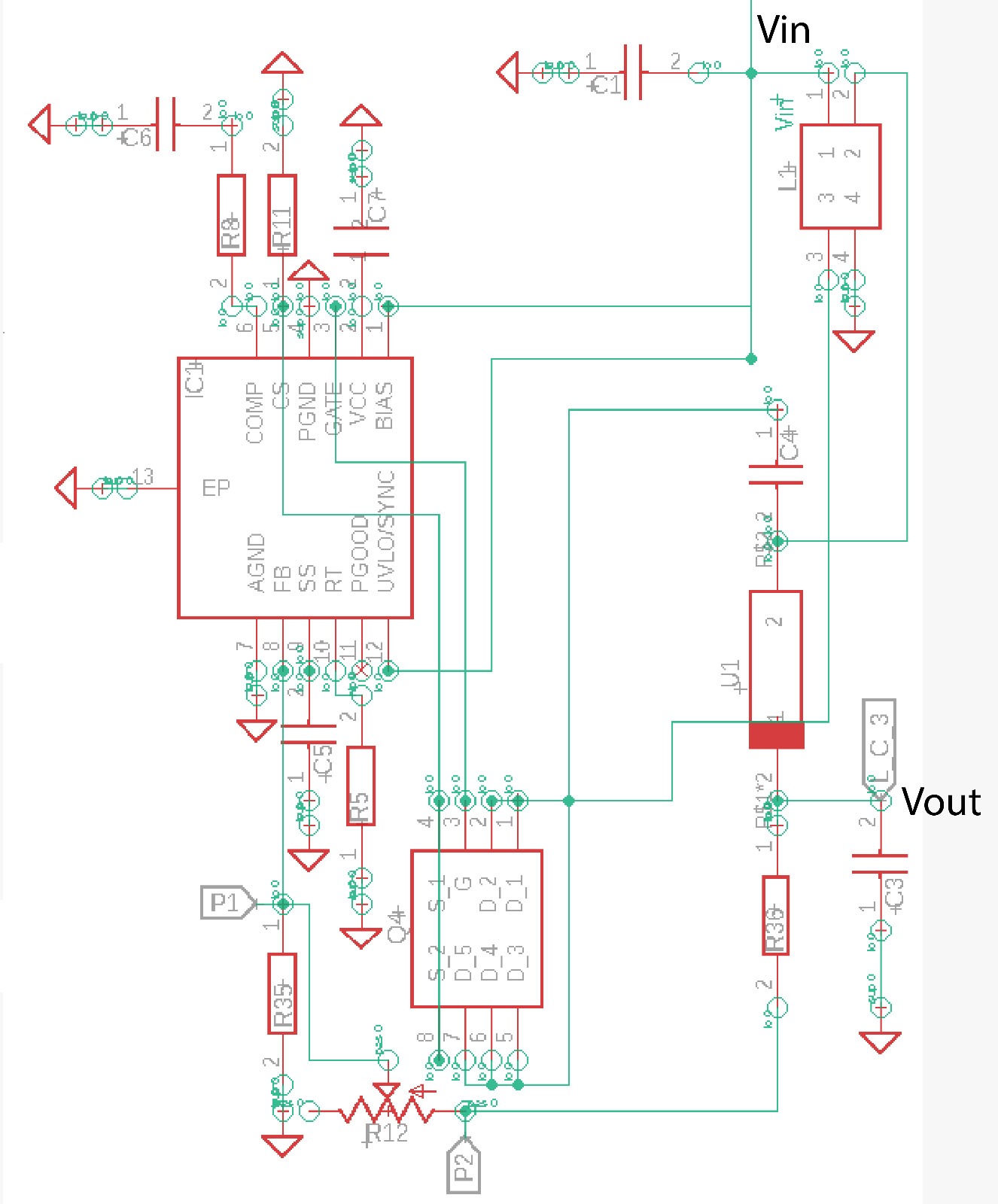

We have some problems with using the LM5155 chip as a SEPIC converter on our PCB. With this converter we'd like to variate the rpm of a DC motor using a 10k potentiometer connected externally to P1 and P2 (see figure). The converter is part of a new product of our company, however the MOSFET used is getting too hot within a minute and during usage the circuit draws more current that the output motor is pulling (in unloaded state). We expect that there is a design flaw, but we do not see the reason behind failure. The requirements of the buck boost is: input voltage: 24v, output voltage, 2-32v, unloaded output current: 0.05A loaded output current 1.1A. De switching frequency chosen is 440kHz. A figure of the circuit is inserted in this message, as is the Bill of Materials for the components used. Did we design something wrong?

Kind regards,

Robin