Other Parts Discussed in Thread: TPS54424

Hi Team,

My customer are using the TPS54824RNV DC-DC Switching power supply on their new Power Board which includes few DC-DC power supplies (Switching P.S and LDOs) .

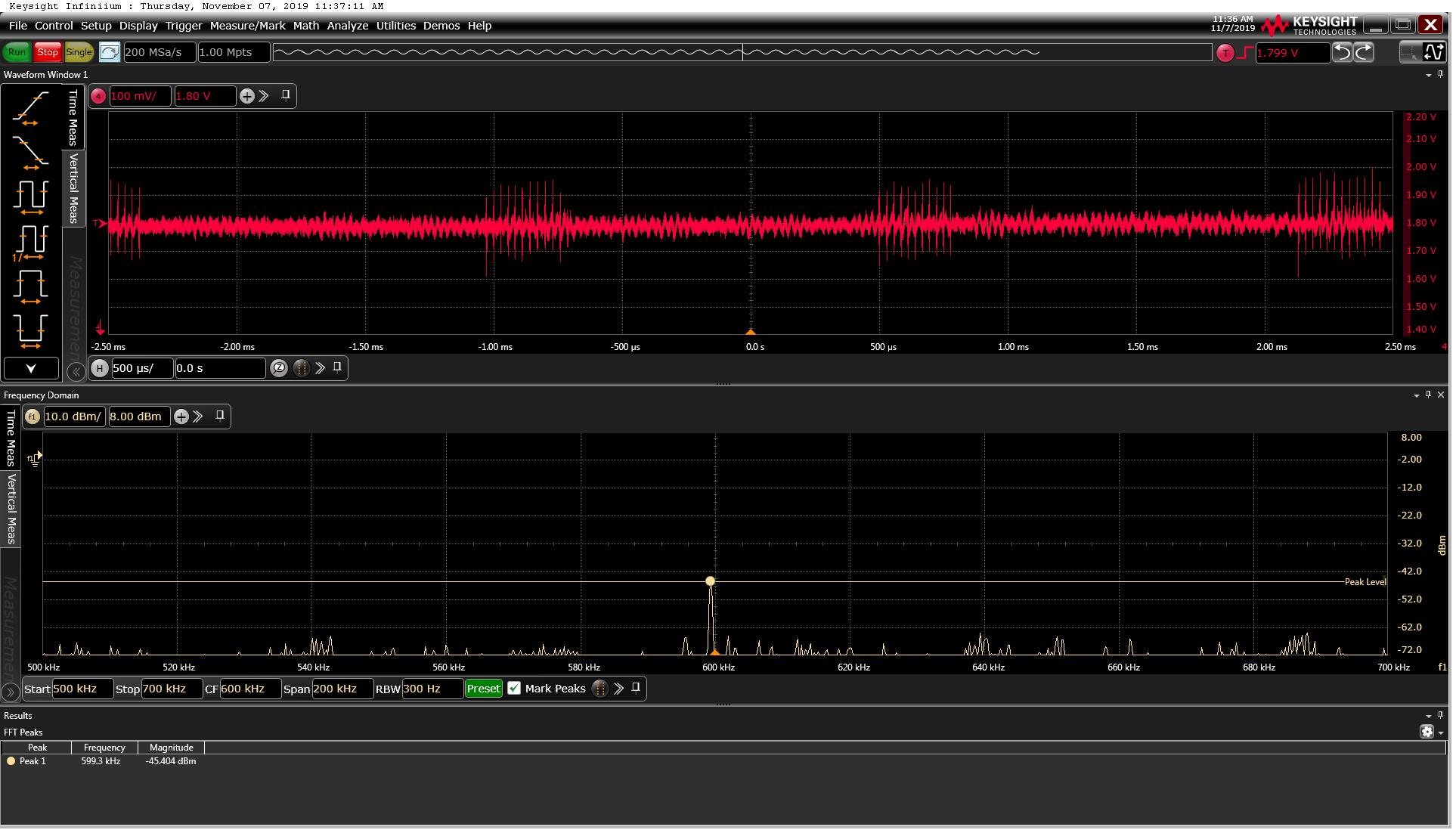

The problem (in one of the Power supplies) that there is noise with DC-DC Switching Frequency (600 KHz) on the Load card which is sensitive to noise.

When they drive the 1.8V to the load using LDO instead od the Switching Power Supply everything is ok.

Please review the below schematic picture and see if everything is ok or suggest them what can be done in order to eliminate/reduce the noise.

Note: The current consumption of the Load is very small and is about 0.5 Amp

Thanks,

Shlomi