Tool/software: WEBENCH® Design Tools

I have designed a regulator which provides 12V @ 3A with an input of 12.5V to 24V. When I calculate the values for the minimum ripple configuration using the LM25085 data sheet description (8.2.2.6 R3, C1, C2) or the LM(2)5085 Quick Start spreadsheet I get R3=12.7k, C1=3300pf and C2=0.1uF . This results in terrible Line regulation, with the output varying from 11.7V to 12.7V as the input voltage is changed from 13V to 24V.

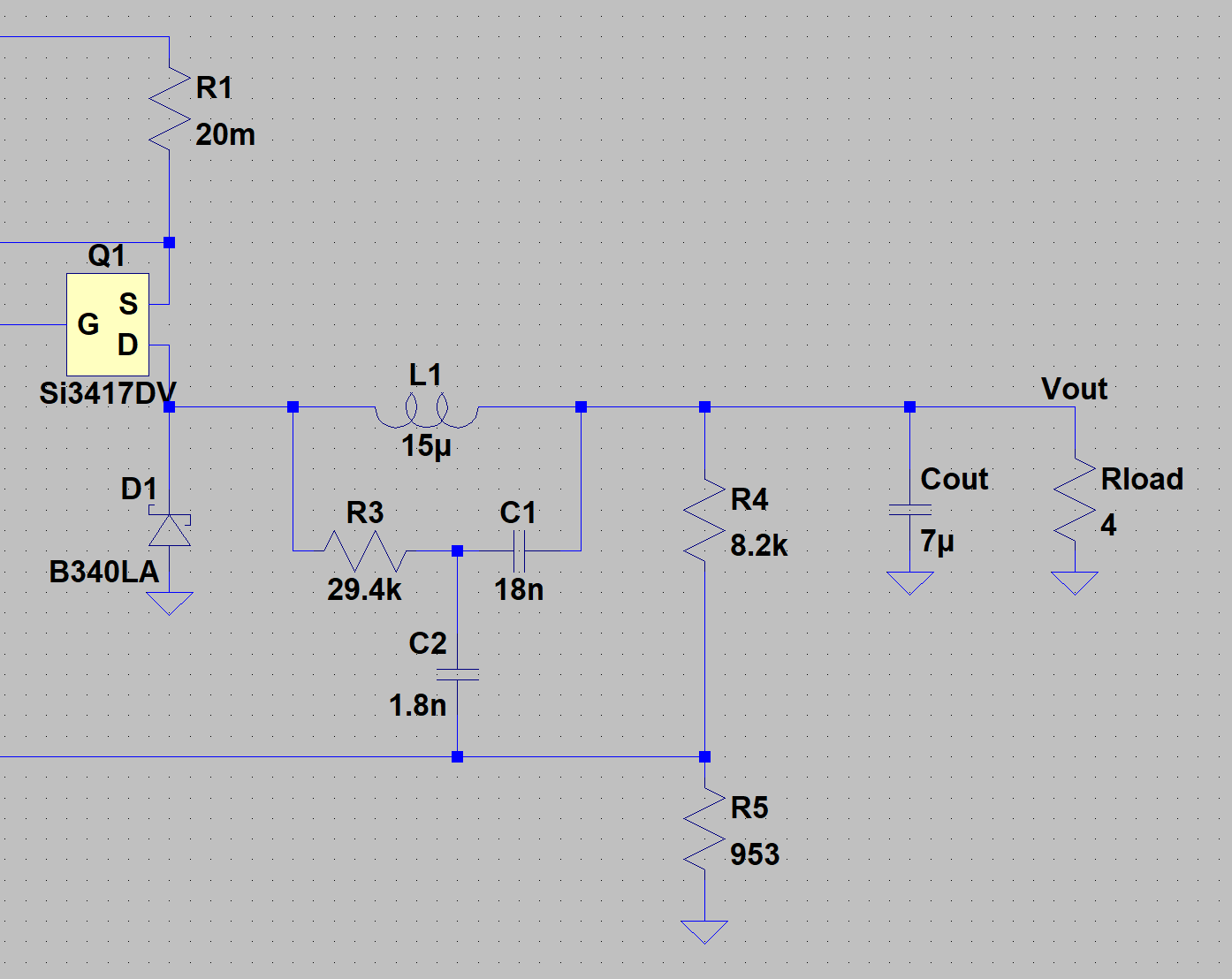

When I used WEBENCH it configured those components differently, with R3=29.4k, C1 = 18nF, and C2 = 1.8nF. These values gave much better results with the simulated output varying from 11.96V to 12.14V as the input was varied from 13V to 24V. Is there any application note, spreadsheet or other guideline for selecting these components in the way that WEBENCH chose them, rather than the approach described in the data sheet? It seems that having a small value for C2, rather than an arbitrary large value like 0.1uF, is very important, but I'd like to know how to optimize the values to match my circuit.