Other Parts Discussed in Thread: TPS63070, TPS63050

Hi,

20% of my boards do not properly start. I use a PS (3.67V) with serial resistance to simulate a battery.

80% of my boards starts even if the serial resistance is 20ohms (10ohm is my requirement), but 20% of the boards require less than 2ohms to start.

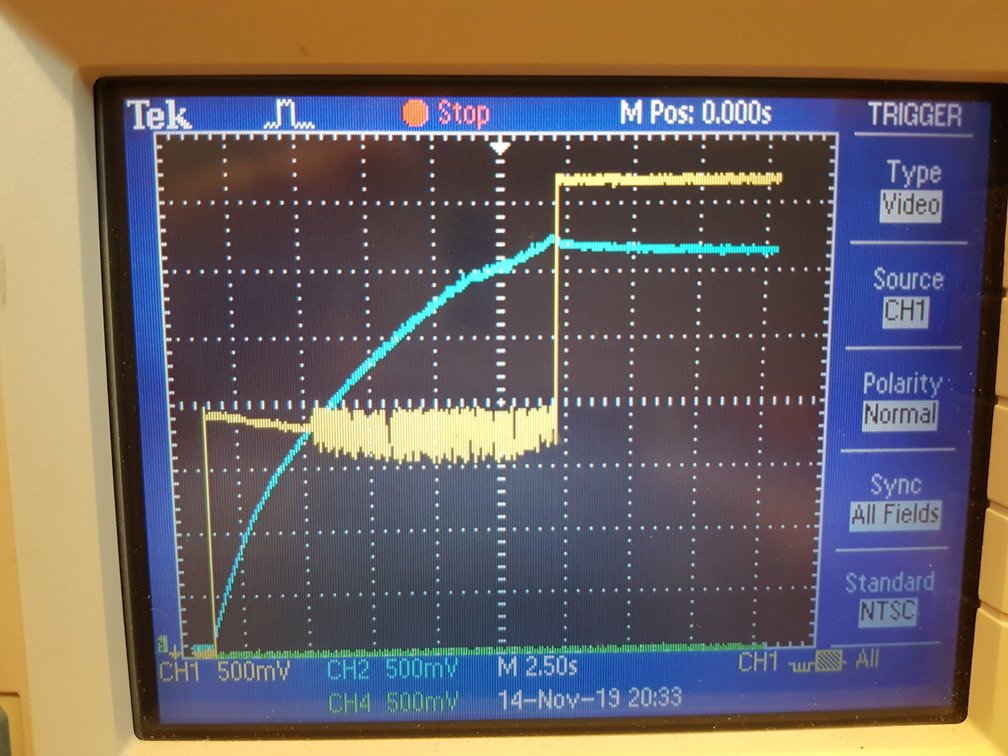

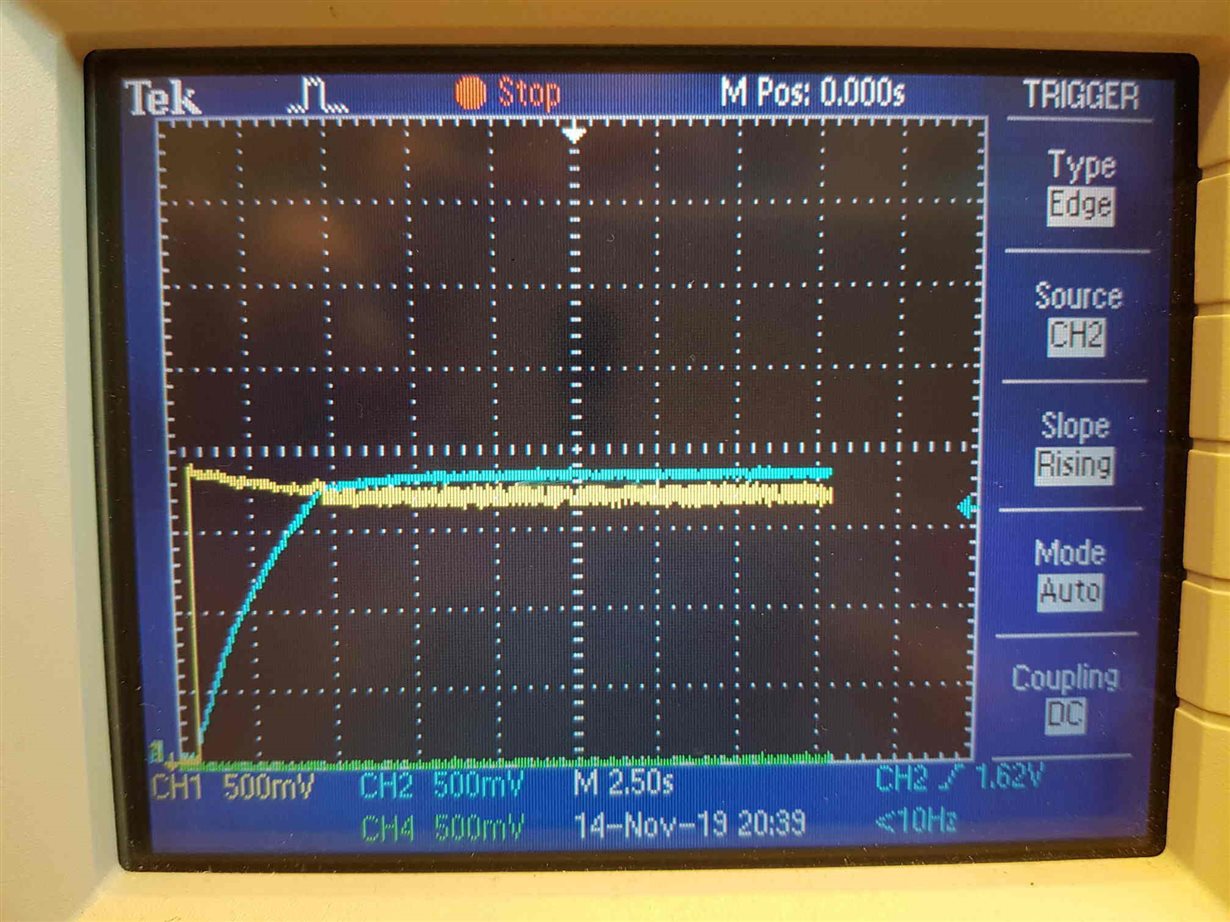

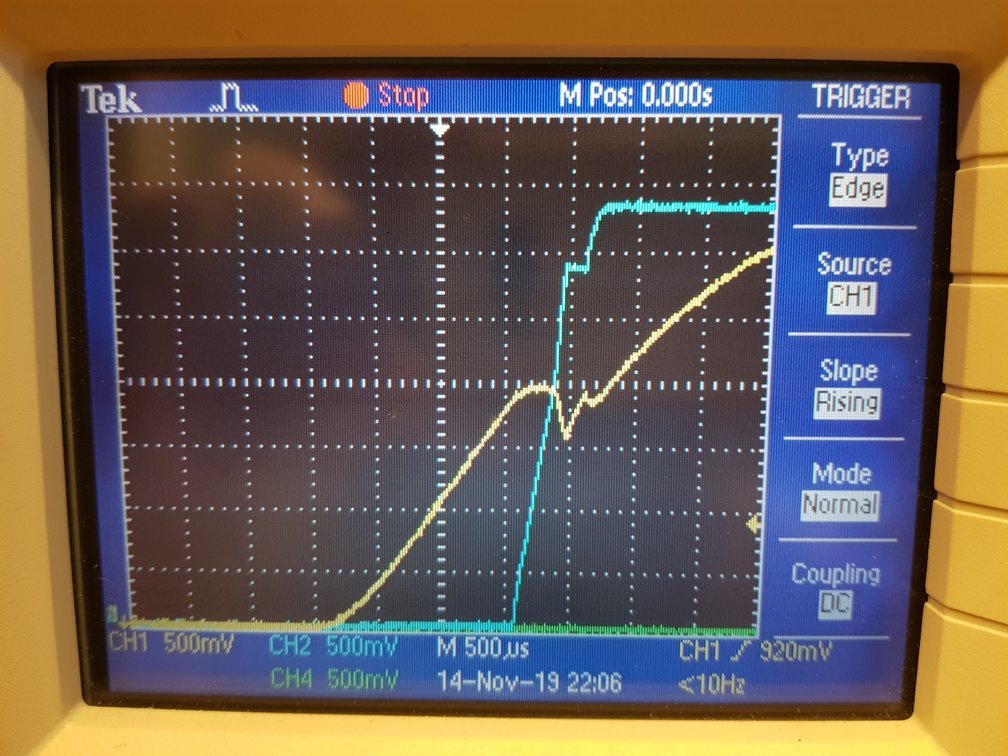

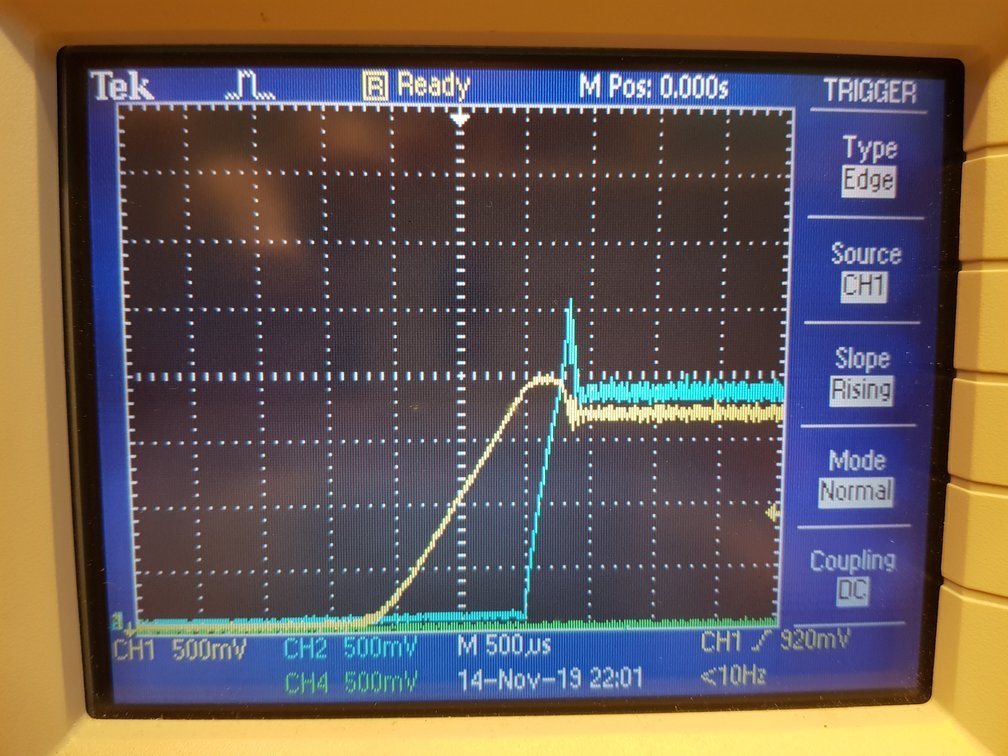

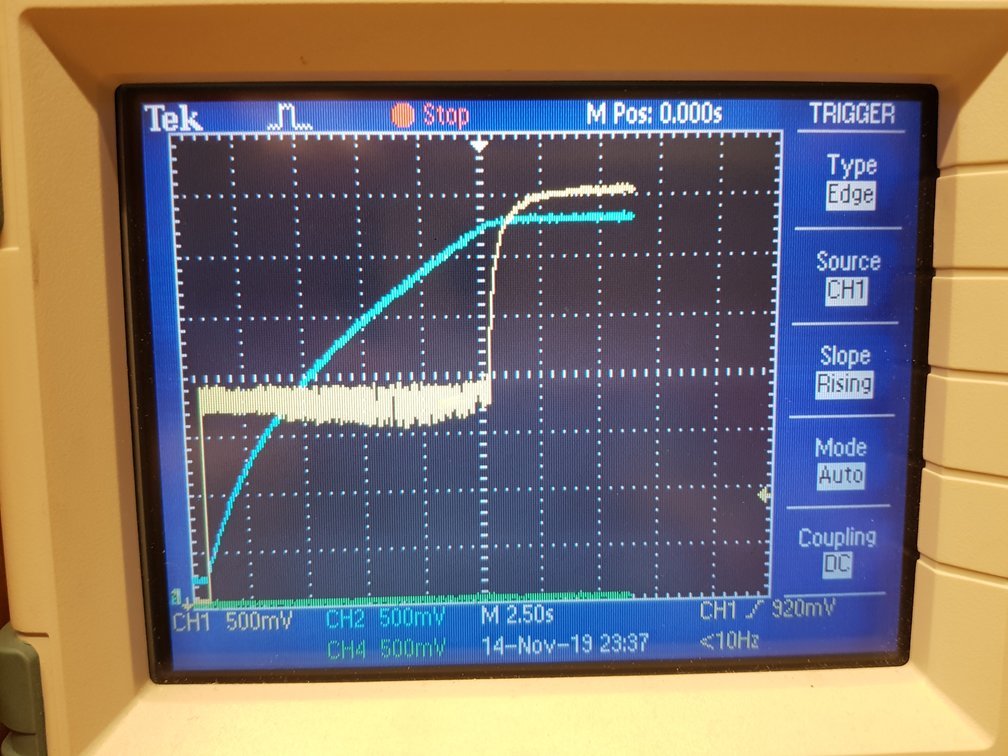

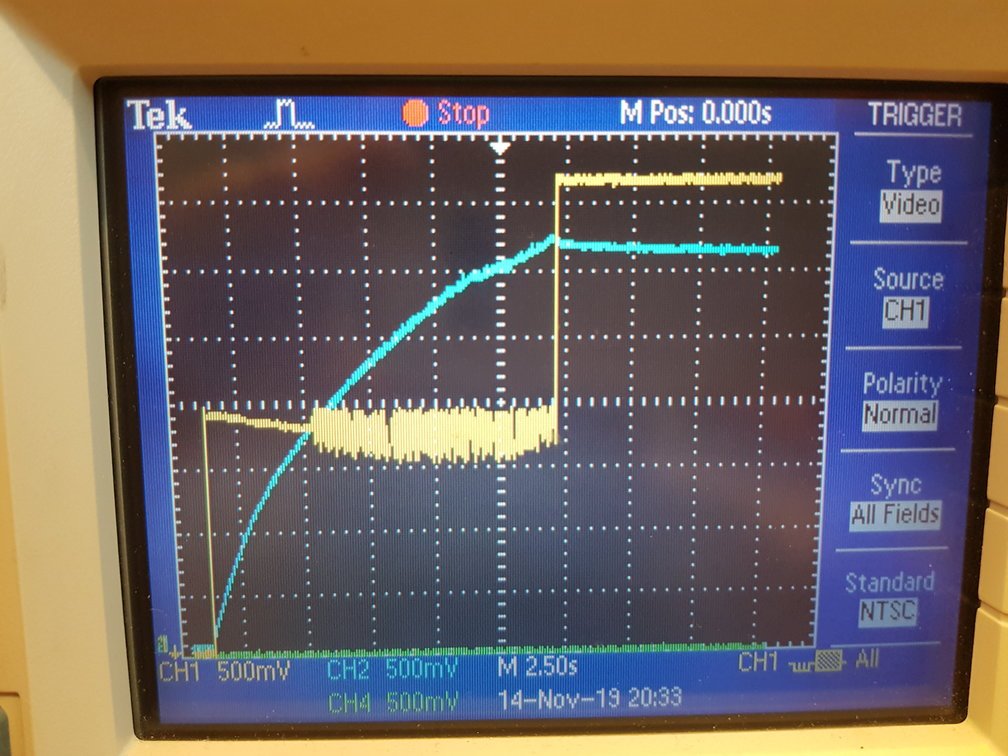

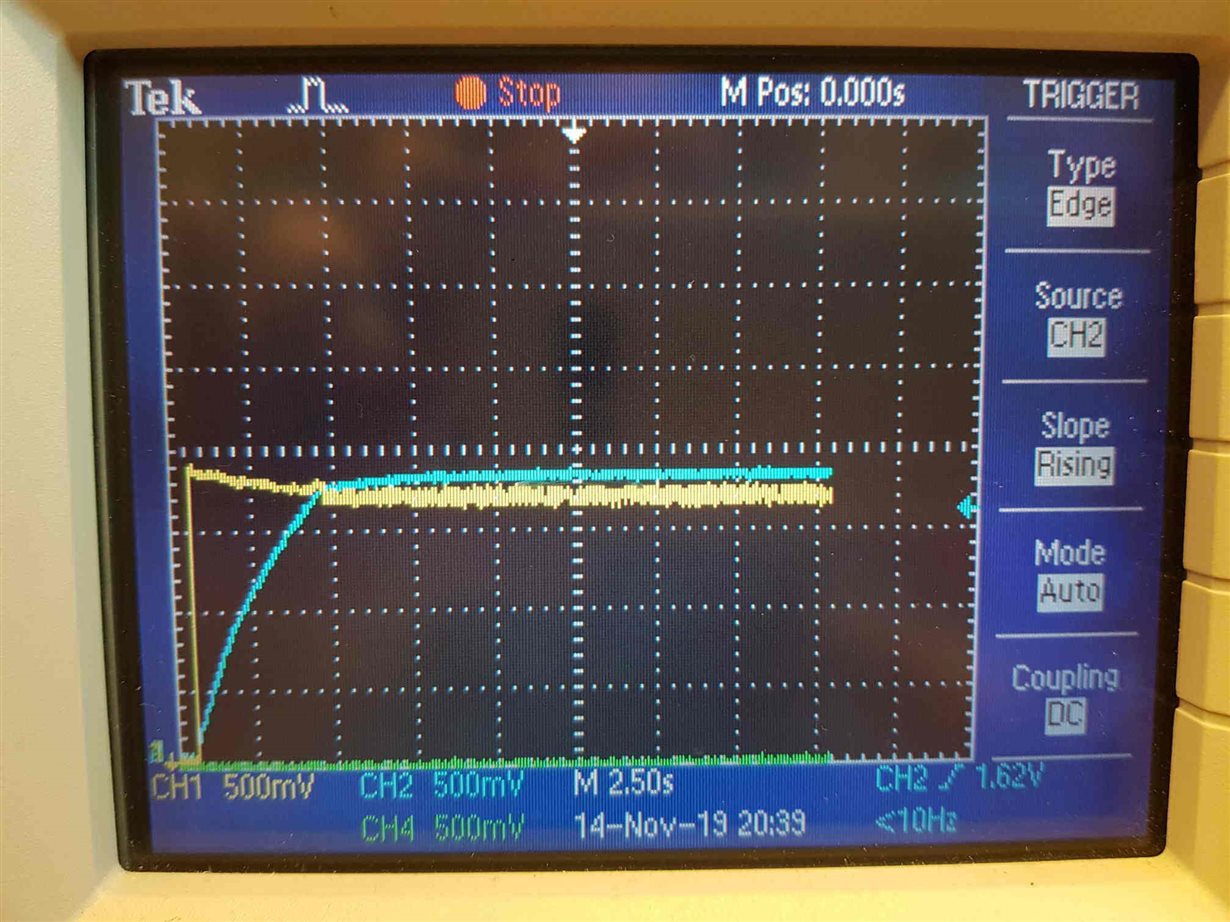

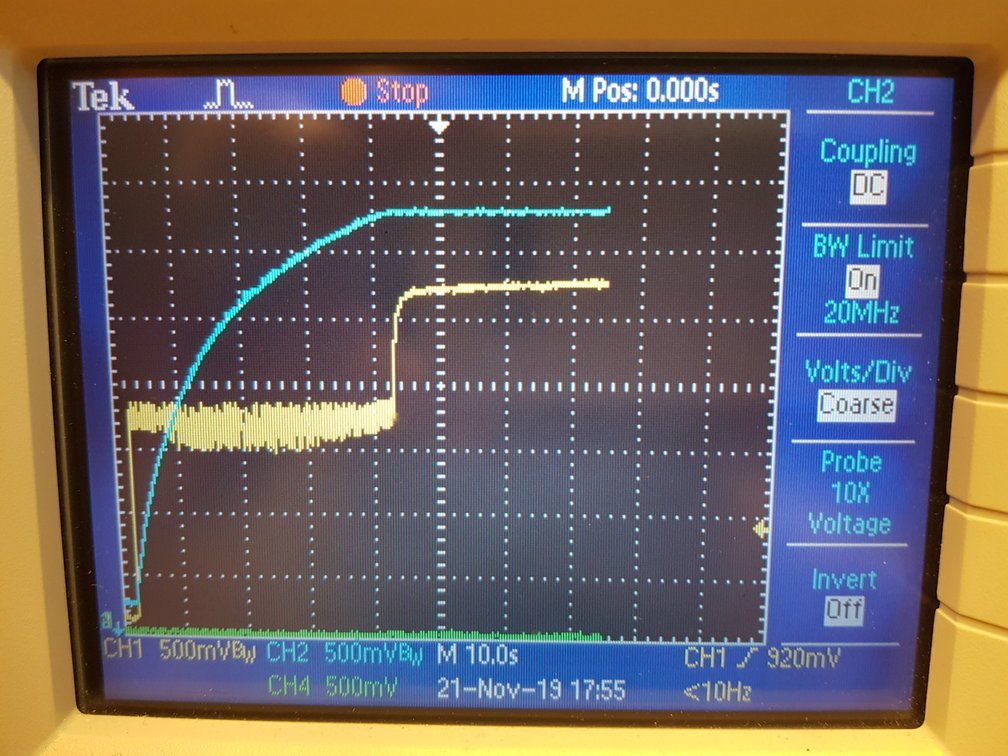

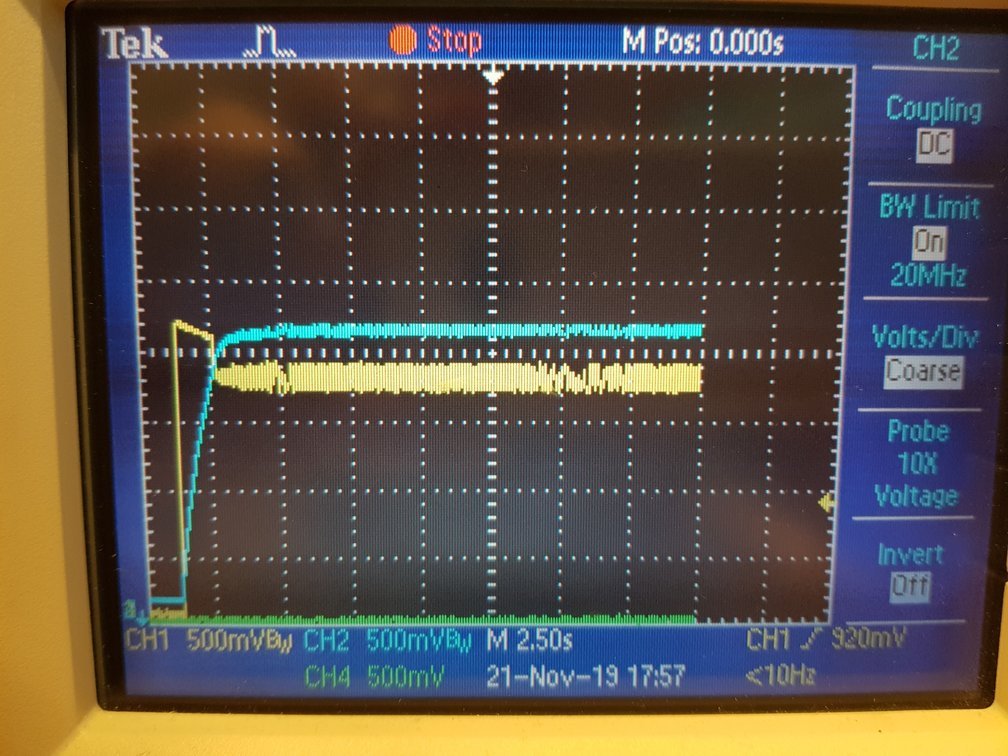

Below shows problem at 10ohms, YEL=Vin, BLU=Vout

Starting

NOT Starting

Regards

CHA