Hi

I am using TPS40210 for a 5V->12V non-isolated converter, when I doing the dynamic load test (1KHz, load_high: 1.3A, load_low: 0.01A, 50% duty), audiable noise can be heard, may be from inductor. Can some one help me to remove this noise?

The design requirements are:

VIN: 4.75V~5.25V

VOUT: 12V

IOUT(MIN): 0.01A

IOUT(MAX): 1.3A

Following is the schematic:

Switching frequency is about 330KHz, Paramter of the components are:

Inductor: 10uH, 7.5A(max); CHF: 47pF; CFB: 0.1uF; RFB: 100Kohm; RIFLT: 1K; CIFLT: 220pF; Output capacitors: 10uF ceramic + 200uF OS capacitor (16SVPC100M, SANYO) ;

Input capacitor: 10uF ceramic + 220uF OS capacitor.

When adding static load (0A to 1.3A, any value), everything are OK: no noise, ripple voltage is very low (less than 200mV);

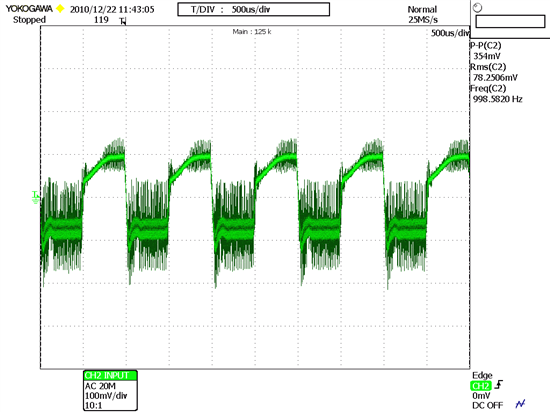

But when adding dynamic load, noise came out; ripple voltage increase a little, about 360mV. Picture of ripple voltage is attached below:

Thanks in advance.