Hi ,

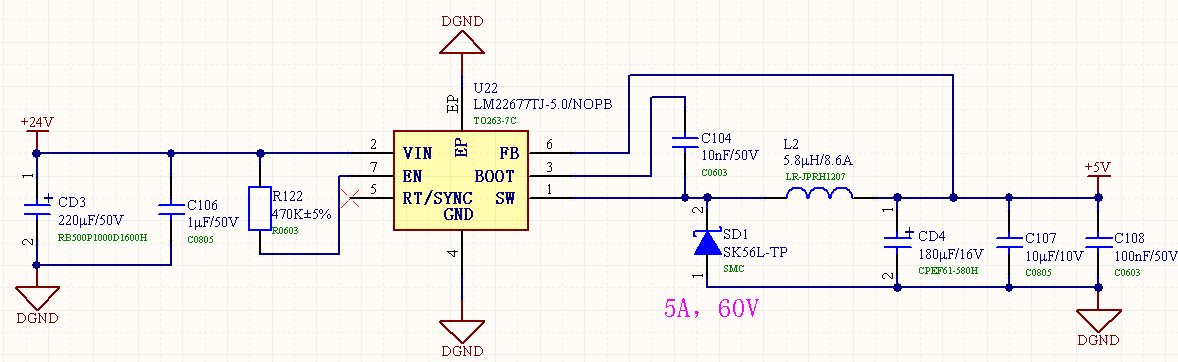

Picture 1 is customer's last generation product and they had produced 10 kilo units without problem. Because they want to change brown-in voltage in new product,

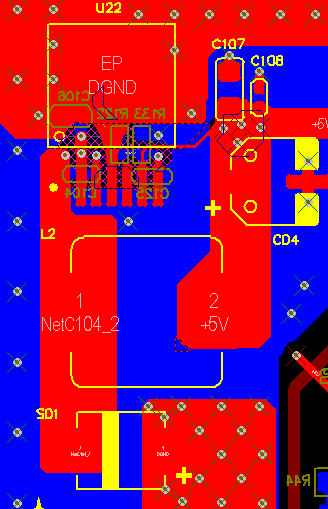

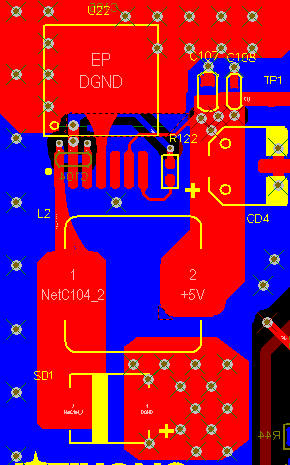

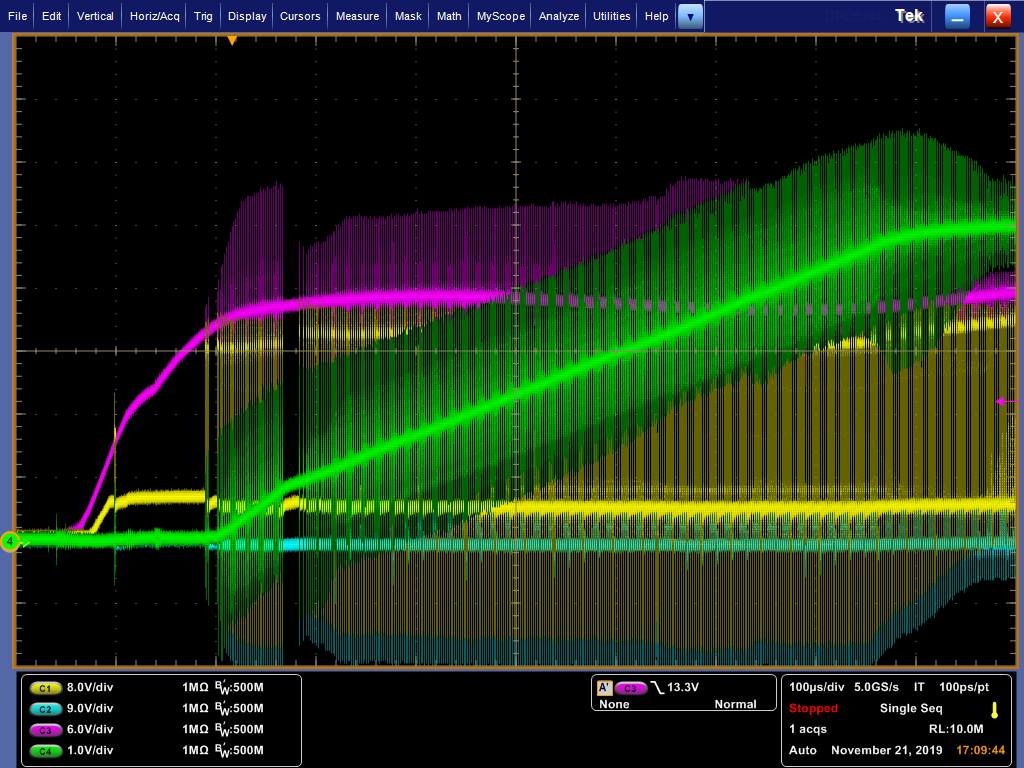

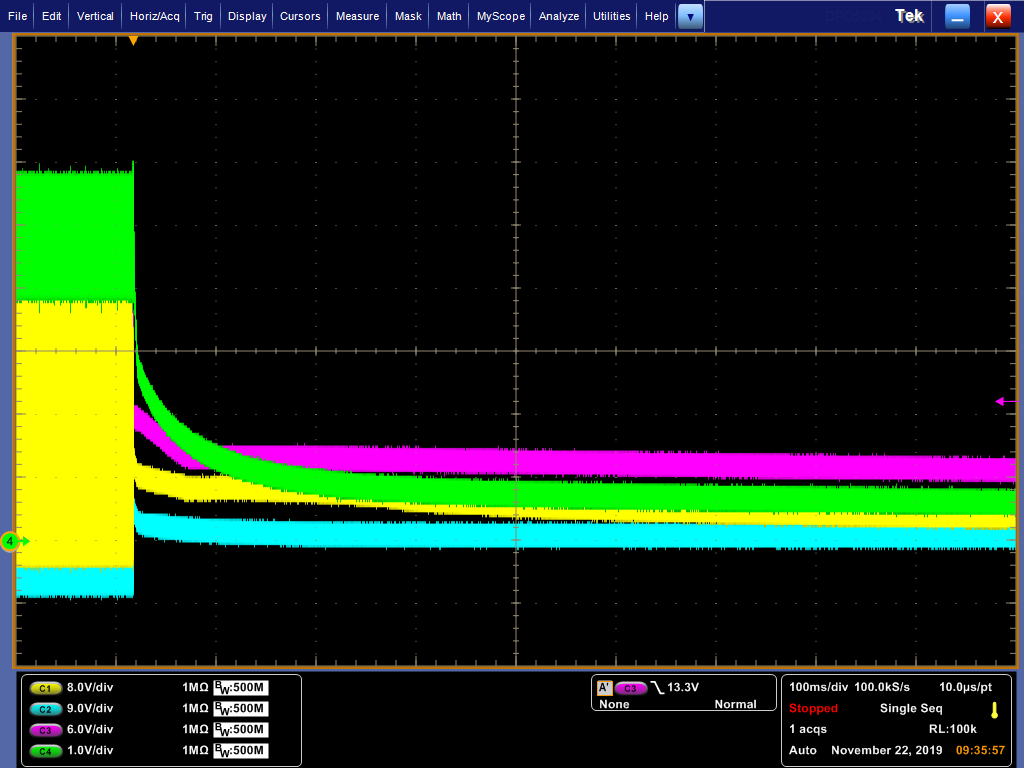

as picture 2 they modify the EN pin from a 470kohm pull-up to a voltage divider, and the other circuit is same as picture 1. Before they had faced voltage oscillation on

EN pin,it is solved by remove the cap connect on EN pin. Now voltage on EN pin is good ,but the chip still damage and the failure rate is 32pcs/192pcs.

Because customer using the same real of chips on mass product and new design so we don't think it is quality issue. Please help me to figure out what will cause this.

Thanks