Other Parts Discussed in Thread: EV2400, BQSTUDIO, BQ34Z100

Tool/software: Code Composer Studio

Hi TexasInstruments- Power-Team,

Our system receives no valid data from the bq34z100-g1 for up to 7 minutes.

For us, 'non valid data' means NAK, I2C bus busy or wrong data (e.g. SOC >100).

Our system is single master. Polling 8 registers every second. Delay between the read operations is >25msec.

At the moment 6 out of 8 new batteries show these anomalies after 4 - 20 days of continuous use (99% of the time only i2c communication. 2 ampere load for 5s per day).

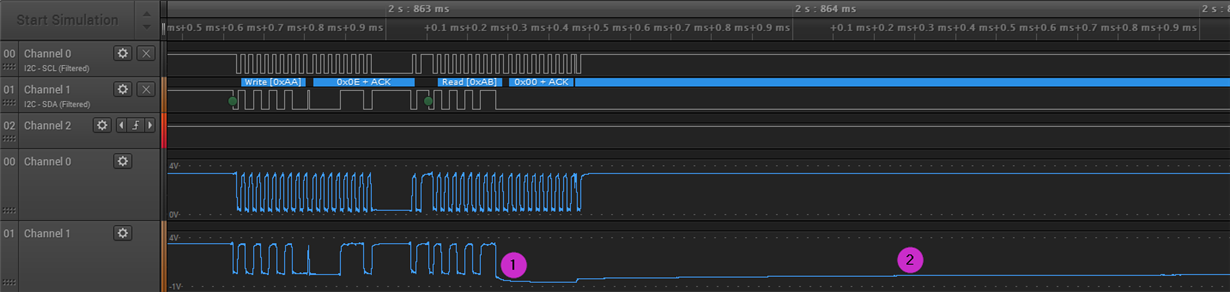

In my lab I managed to capture a bus stall of 0.8 seconds (see picture below). At (1) DATA goes low (2) Our software tries to send STOP to reset the i2c-bus (3) the battery releases the DATA line (4) communication reestablished.

- Is there a state in which the bq34z100-g1 keeps the i2c data/clock low for longer than 20ms? If so, what is the maximum time for this?

- I read in the datasheet that an autocalibration is performed when going into SLEEP mode. [ DATASHEET: http://www.ti.com/lit/ds/symlink/bq34z100-g1.pdf

- How long does it take?

- What is the value of BUS LOW TIME (Datasheet p.36)

I am fully aware that our software also plays a part in this. But in our software, there's no reason for a 7 minute break - I hope there's something for that in the bq34z100-g1.