Hi team,

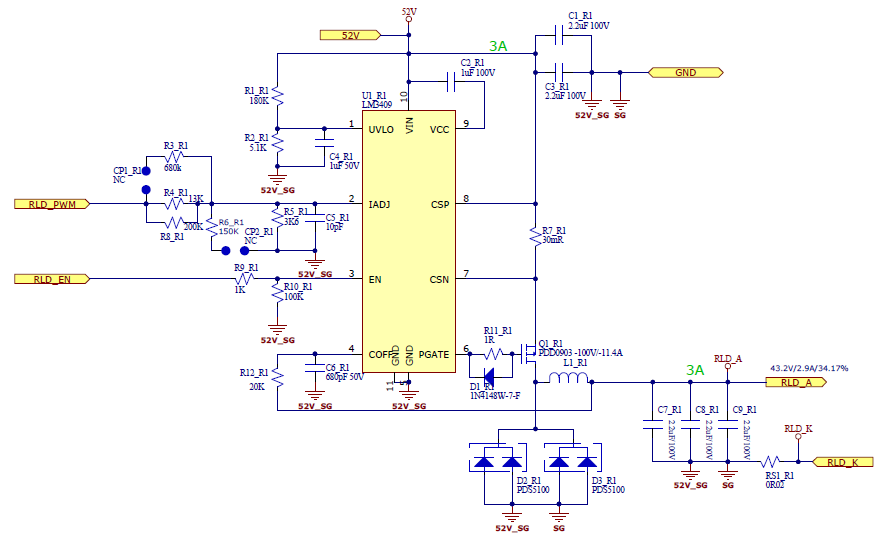

My customer is using our LM3409 for LED driver at their system.

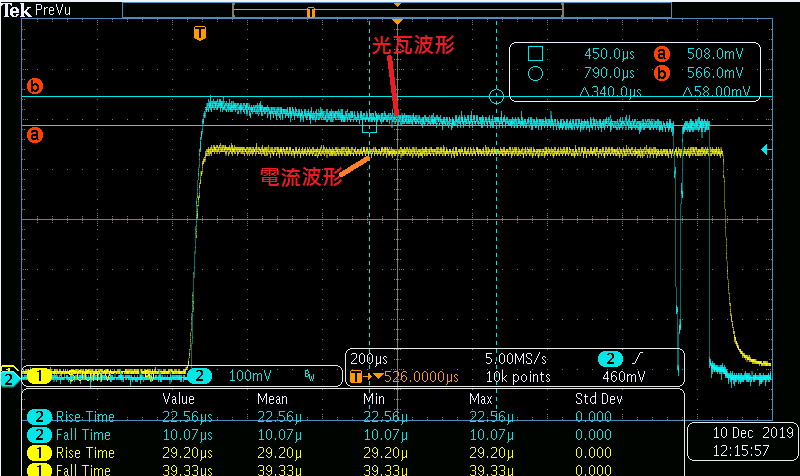

They have measured the light power and current waveform at load current transient as below figure.

They would like to improve the performance of overshoot behavior.

The schematic is as below. Could you kindly provide some suggestion? They also mention whether we can implement a step current load system to prevent the overshoot behavior as below figure. Could you guide us how to implement it in our system? Thanks.

CH1: current, CH2: light power

Step Current waveform