Tool/software: WEBENCH® Design Tools

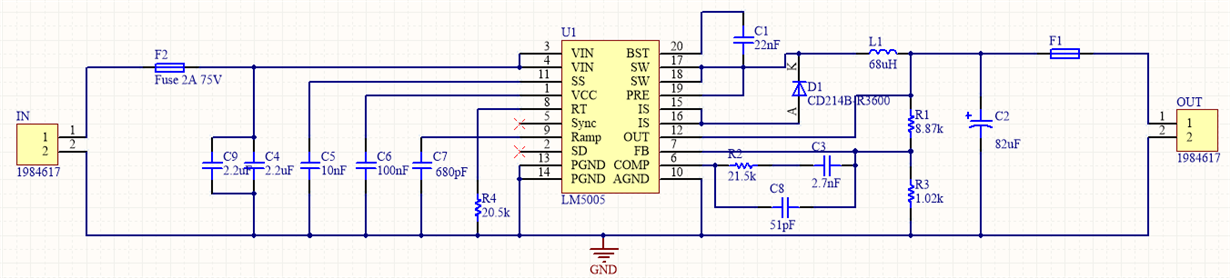

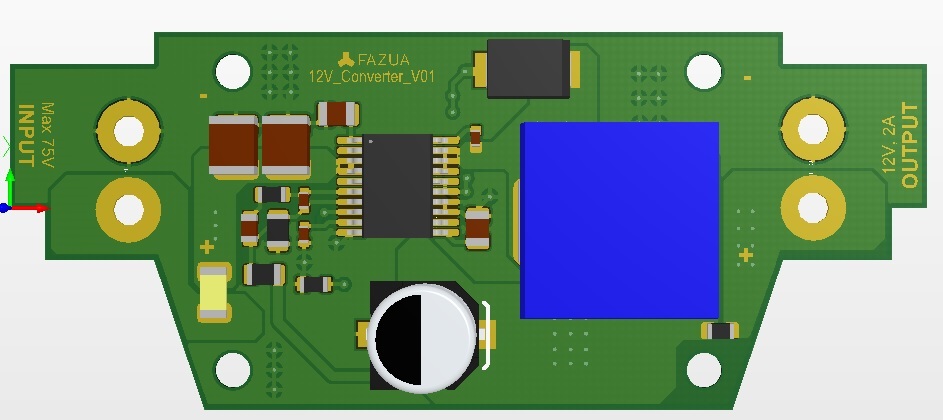

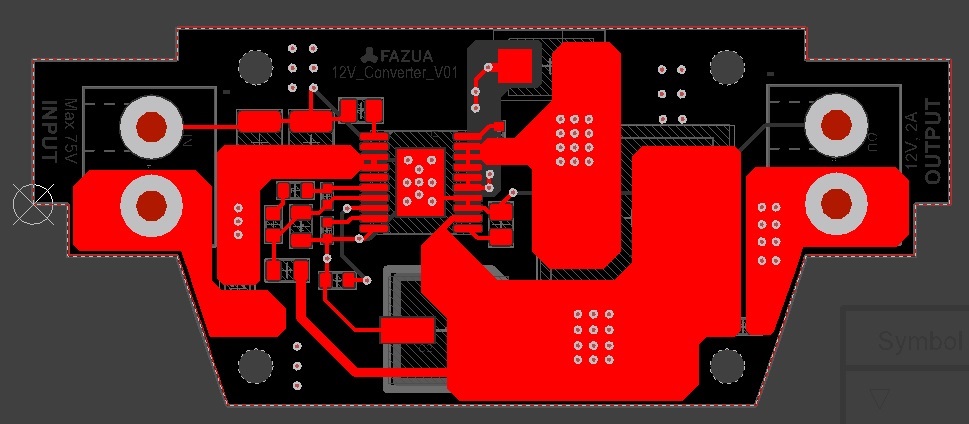

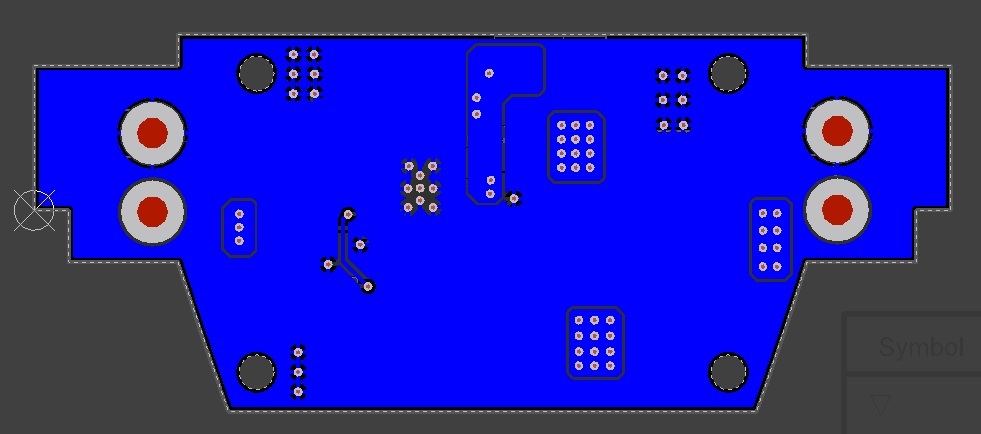

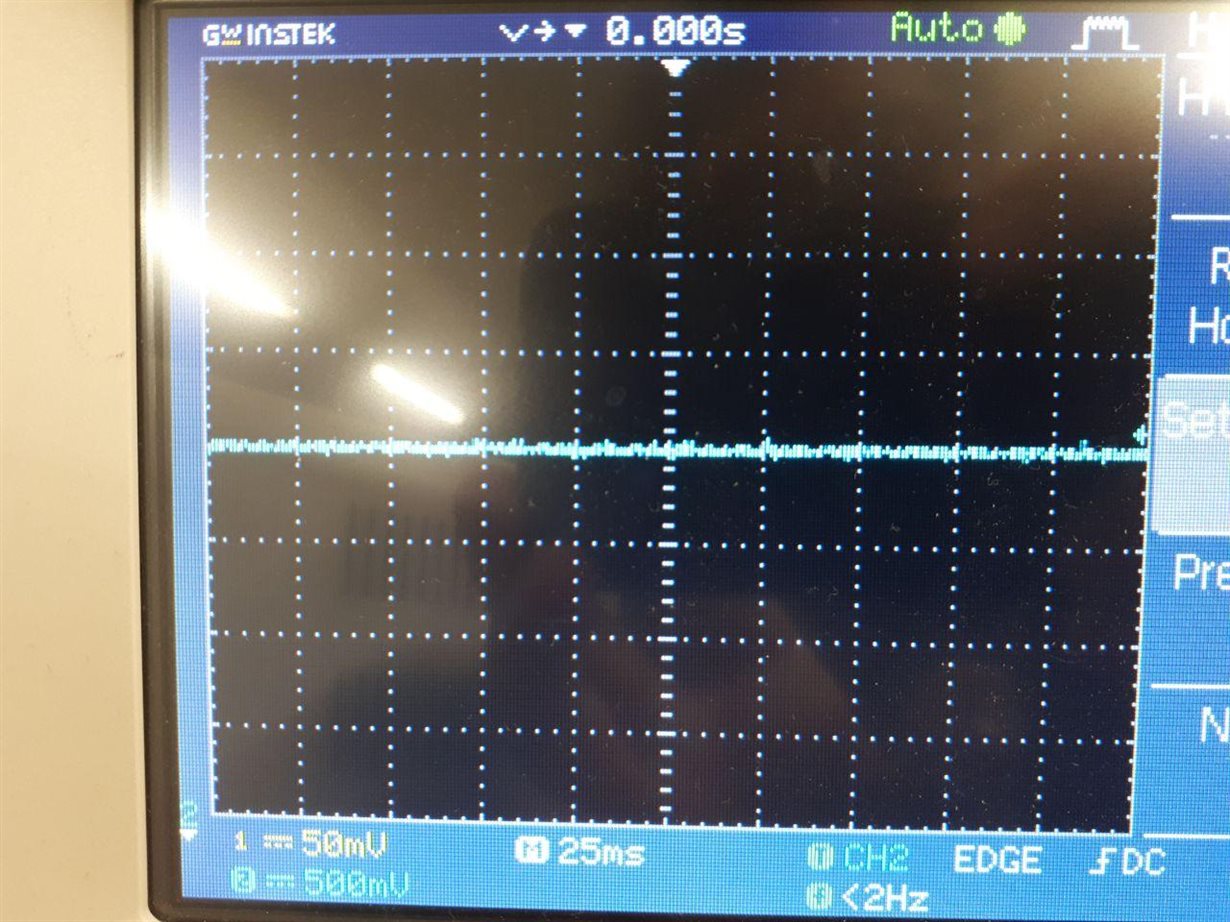

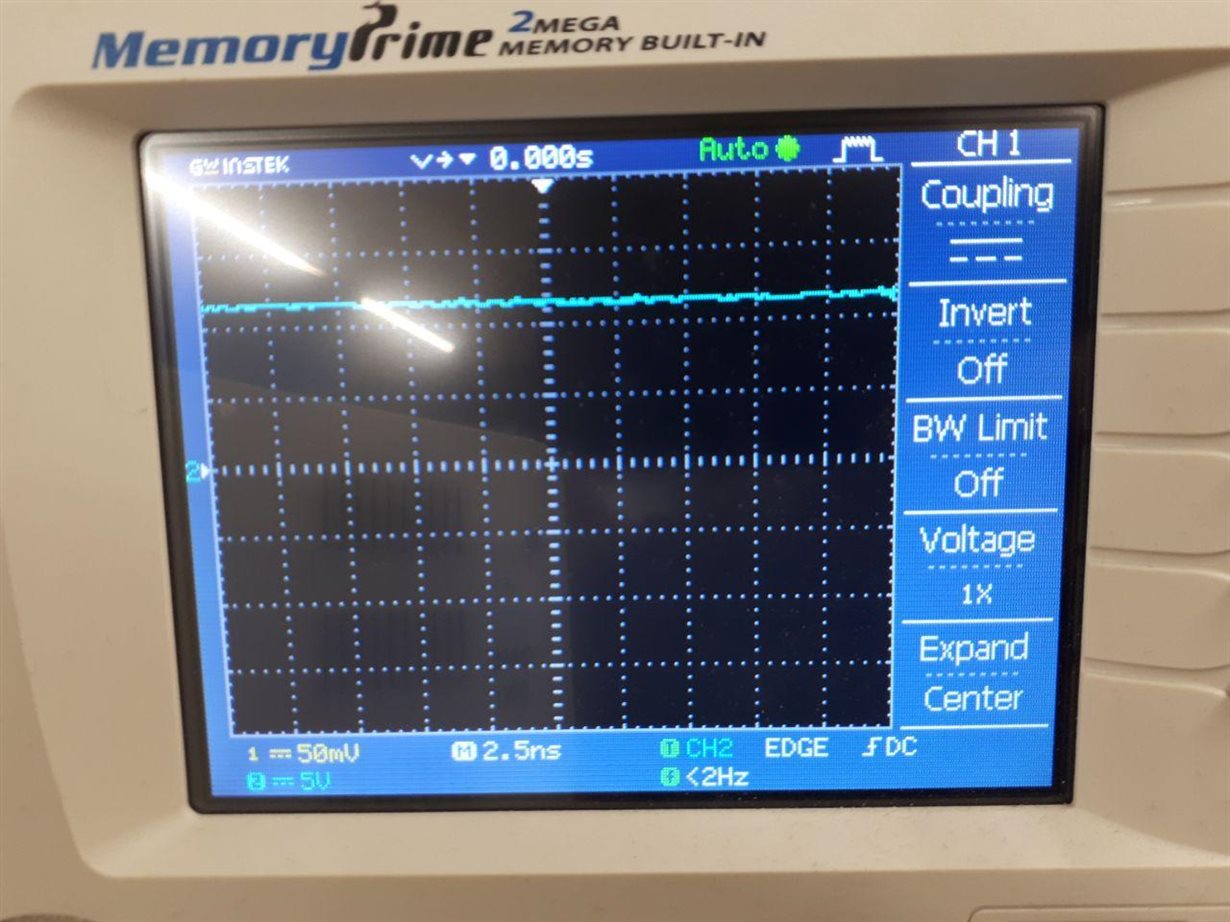

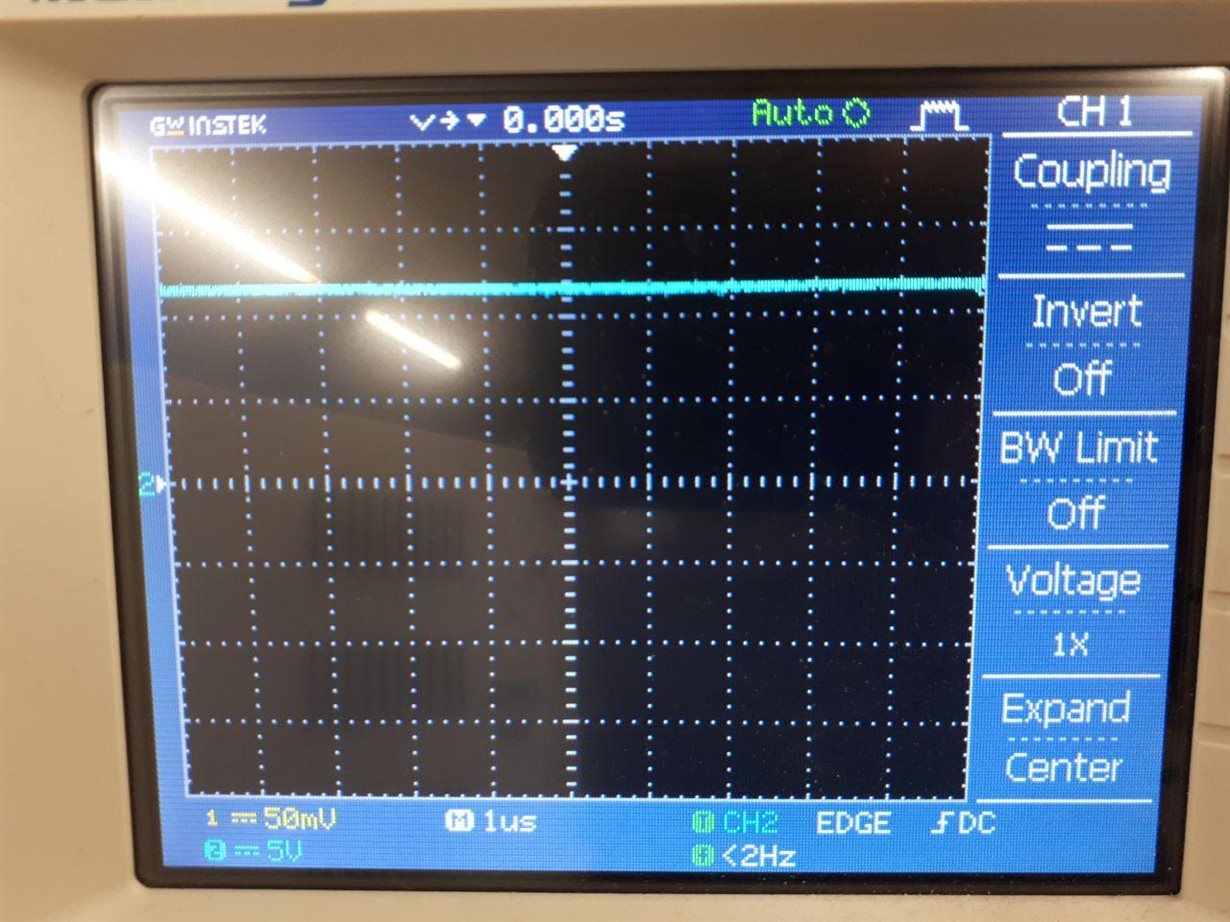

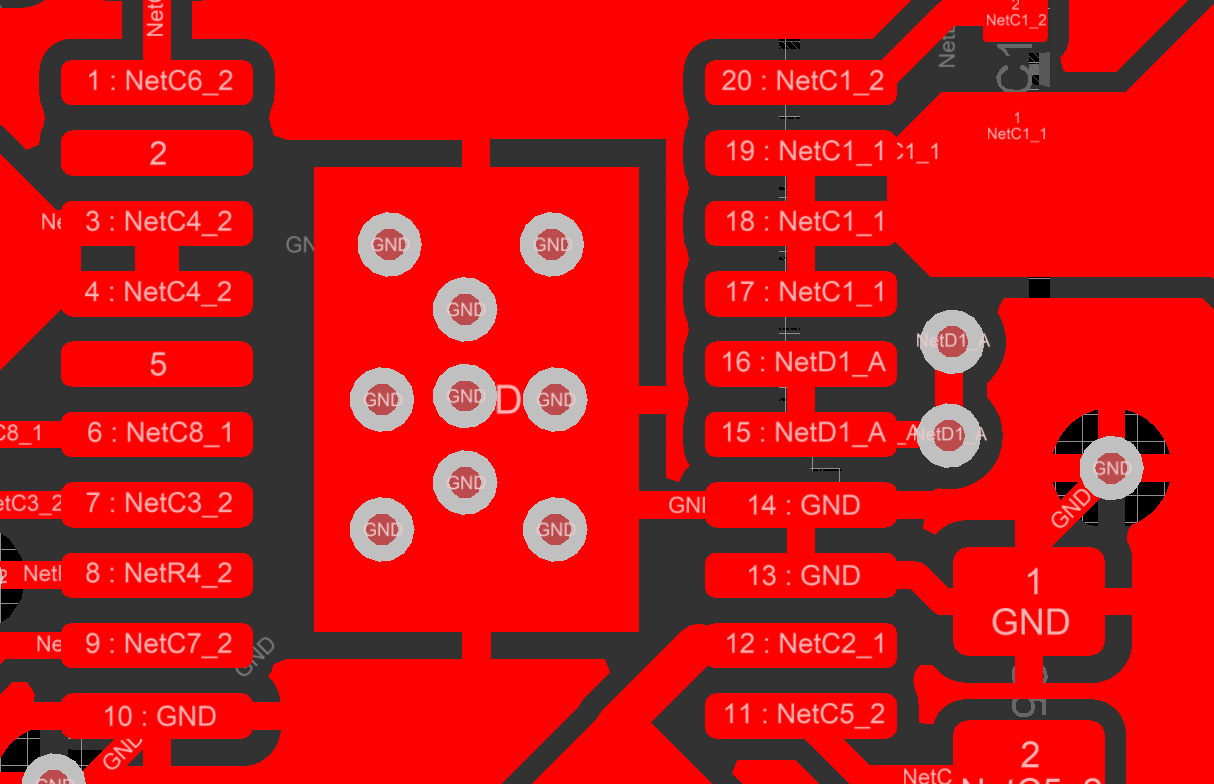

I have designed a DC/DC converter using LM5005 and based on TI Webench tool. My designing criteria is INPUT: 30-75V, OUTPUT: 12V,2Amps. After producing and testing sample PCB. The LM5005 burned at 300mAmps!!! I have few questions: 1- why it happened? 2- Is it possible to open a case and explore the problem? 3- what is the solution? is there any more reliable alternatives?

Regards,

Jafar