Other Parts Discussed in Thread: GPCCHEM, BQSTUDIO, BQ27742-G1

Hello ,

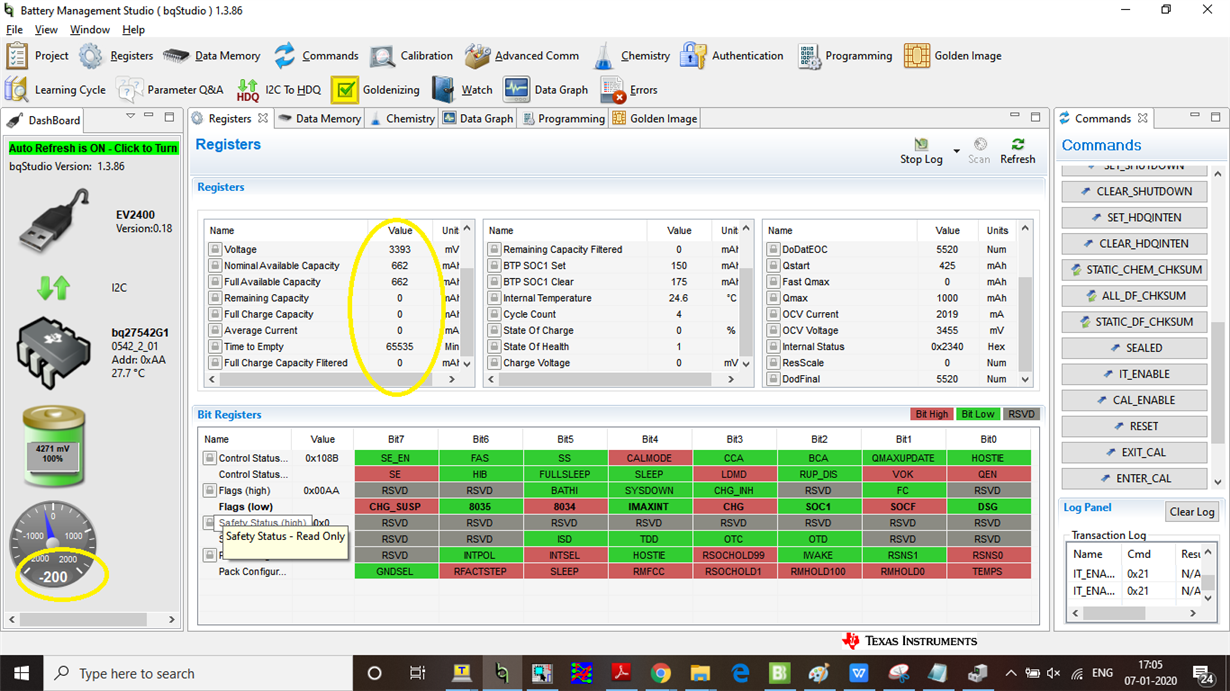

We are using above part in our system but this will not able to give proper reading.we connected above part in TI tool (Battery Management tool)

Used attached image for your reference.

We are discharging the battery but tool not able to detect that one .

We are using 12000MAh Battery .

Tool also not able to detect the battery capcity and other reading like charging.