Dear Sir/Madam,

Subject: Issues with TPS63031DSKR/design, Battery gets dry out soon.

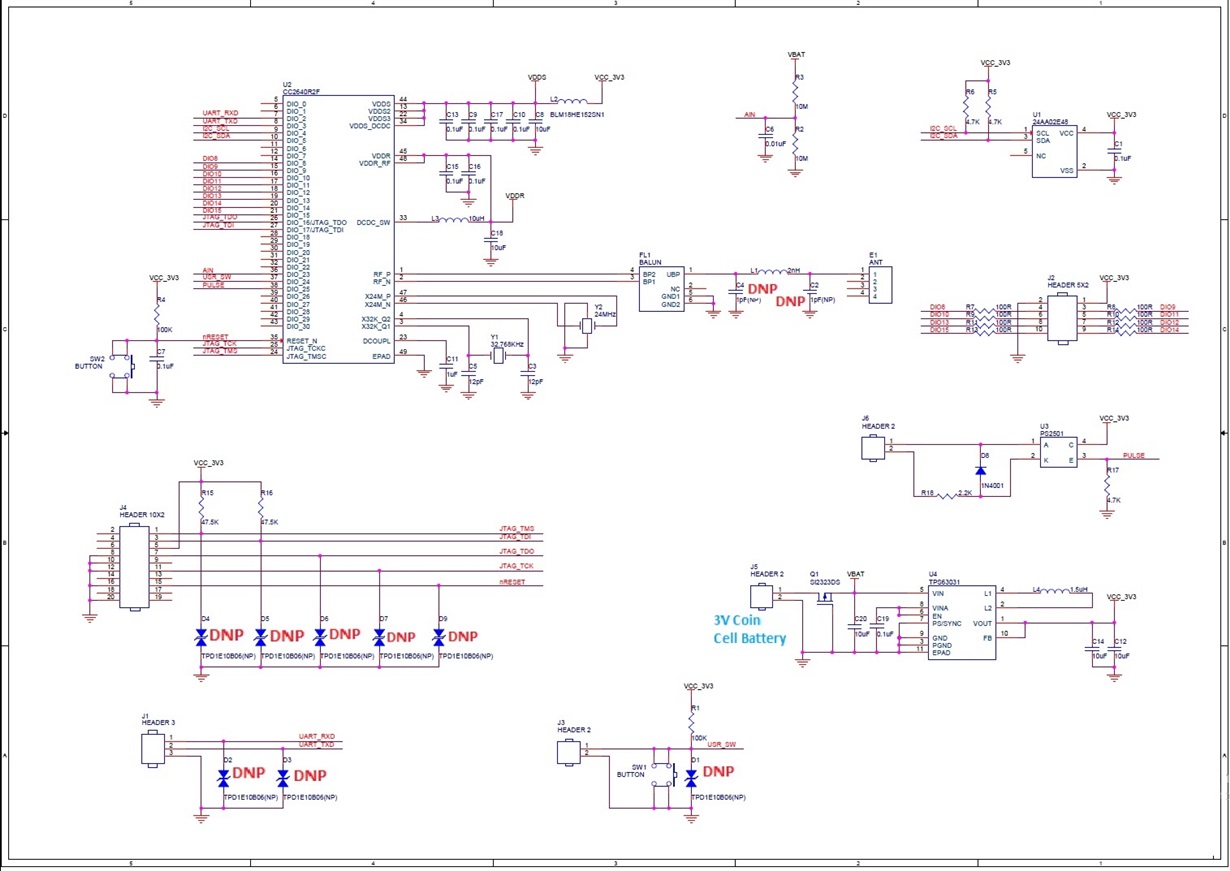

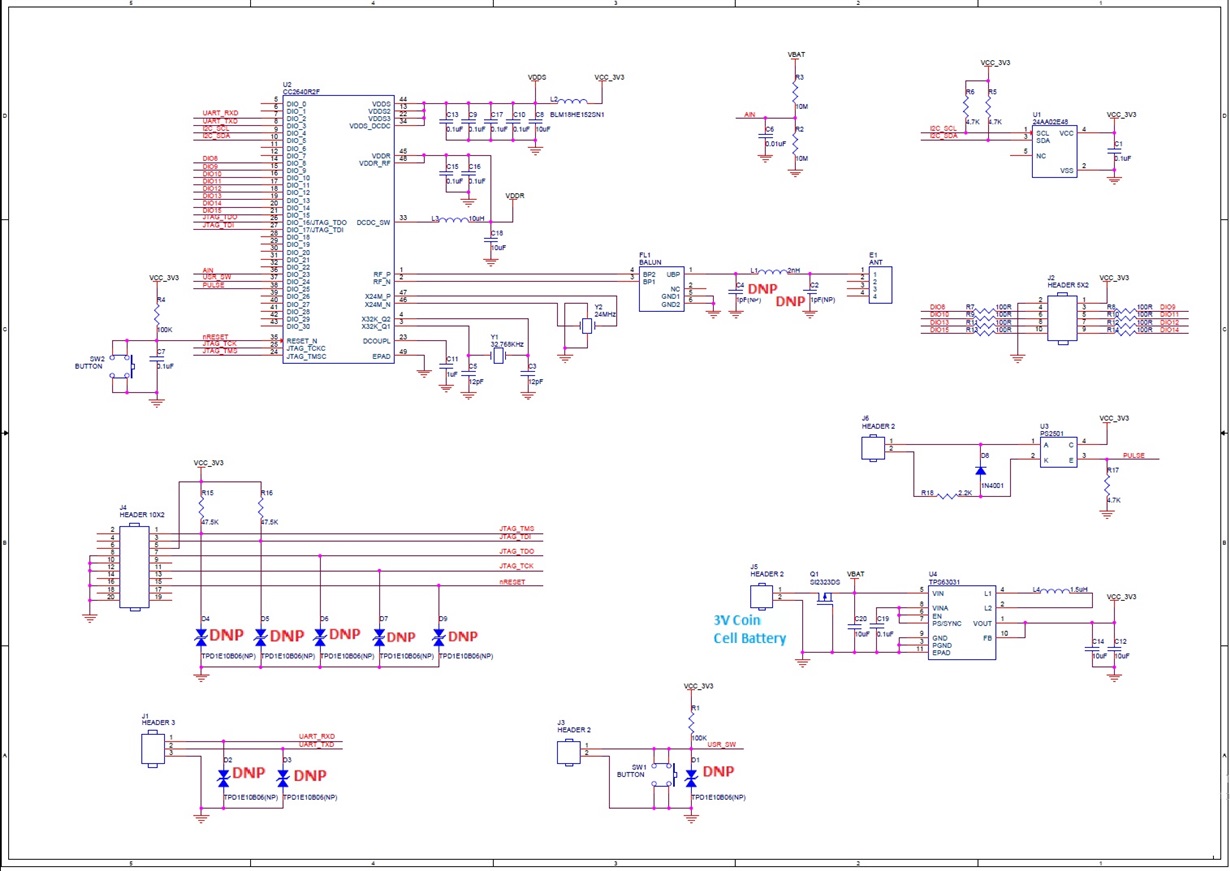

We are using TPS63031DSKR Regulator(U4) for powering CC2640R2FRGZR(U2) as shown in the attached schematic. We are using 3V Coin Cell battery for powering the board.

We are having 3 different Test Cases with the same board and modified schematic for same application (Industrial Machine Automation):

1. Without Regulator- Schematic 1: We have removed the Regulator (U4 as DNP), Directly given Battery Voltage to CC2640R2FRGZR.

RESULT: Battery Backup was Minimum 2days.

2. With Regulator-without Power Saving Mode-Schematic 1:

RESULT: Battery Backup was 1days.

3. With Regulator-with Power Saving Mode- Schematic 2:

3. With Regulator-with Power Saving Mode- Schematic 2:

RESULT: Battery Backup was Minimum 2days.

In Case 3 With Regulator-with Power Saving Mode, We put 2 boards for testing, both boards working fine for 7 days. After 7 Days, only one board is working fine with 2 Days battery backup and its still working.

Another board battery will get dry out within one or two hour, but giving Vout is 3.3V. I have removed the MOSFET (Q1) shorted Drain-Source and tested, but issues not solved. I have compared input Impedance and Output impedance with fine board, Output impedance (Vout w.r.t GND) was same for both the boards but input impedance (Vin w.r.t GND) for the fault board was 200 Ohm and in fine board it’s a infinity or >4Mohm.

Kindly help us to find the problem where it exactly and need to solve these issues.

- In which part there is a issue? Fault was In the Regulator?

- What is the Reason for the issues?

- How to overcome this issue in future? Can we really trust the regulator?

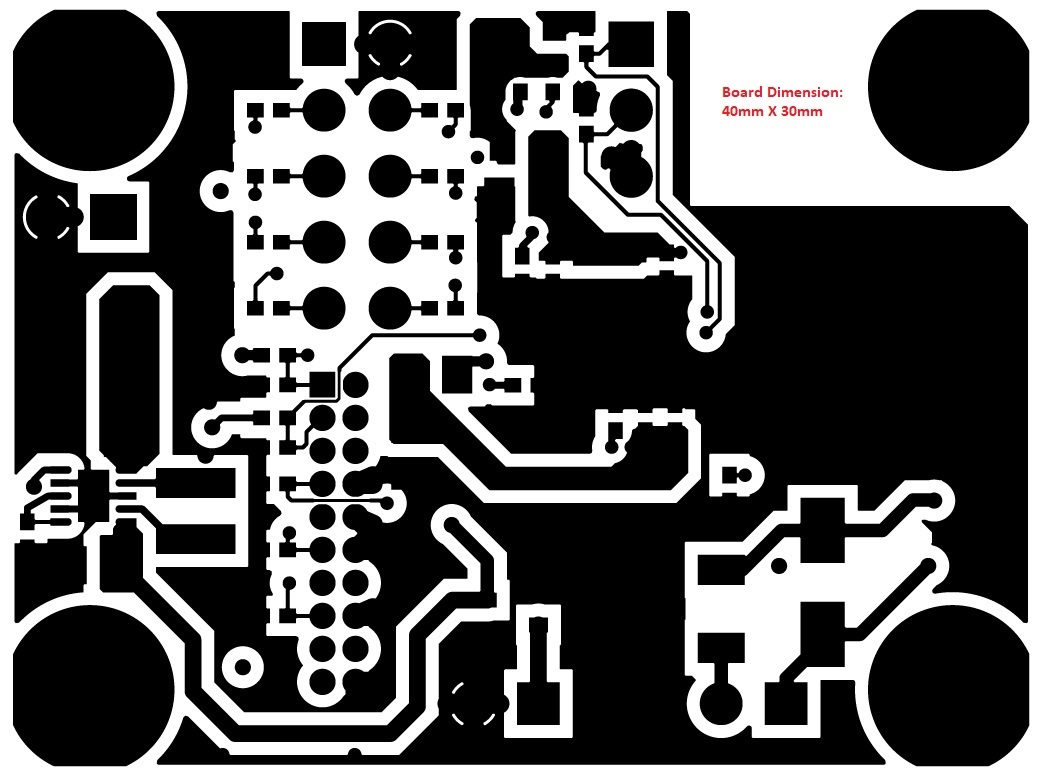

- We are planning to go for bulk production due to the requirement, until the issues solved we cant proceed for the production. PFA the Gerber Image, Schematics and kindly confirm is there any issues with the design?

- Your advises will be more appreciable for improving product efficiency/design. (4 Layer Board: Inner Layer1 is Ground and Layer2 is 3.3V)

We are Looking Forward to Hearing from You Soon.

Regards,

Naveen K