Other Parts Discussed in Thread: BQ78350-R1, BQ76PL536A

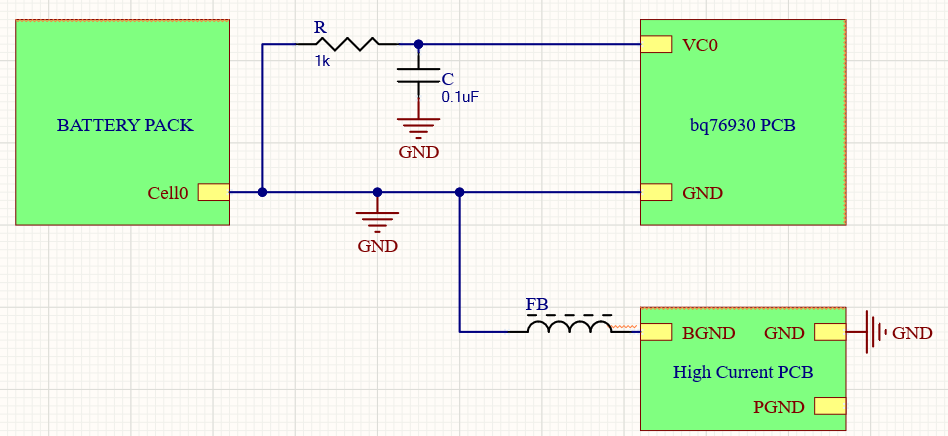

We are currently designing a BMS/Controller board for a low voltage battery pack. The board includes TI's bq76930 and bq78350-R1 for monitoring and fuel gauging purposes.

The battery will be charged via alternator and the operating environment will be noisy. We have some worries about EMI/EMC and transient/surge susceptibility of the board.

As different from the typical application we added;

- Strong TVS array on the PACK side of the board for transient and surges in order to protect the FETs and to keep the transients away from the cells, so the board

- 600R (@100MHz) ferrite beads to the cell inputs

- I've seen that TI adds some low capacitance capacitors (~3300pF) to the cell inputs as an EMI filter (bq76PL536A). Would that be required for bq76930?

- Considering that the board have transient/surge filter on the PACK side do we still need a precaution on the cell inputs?

- Does bq76930 require a zener diode on the cell inputs in order to clamp the voltage to the ICs limits for hot plug-in etc. conditions?

- Does the reference filter from the datasheet for current sensing inputs (SRP,SRN) enough the filter the noise in this environment?

- Should we make some changes on the I2C and SMBus lines (which are <12cm/5")? Like stong pull up?

- Would you have another suggestions on the optimization of the bq76930-bq78350-R1 circuitry?

Thank you,