Other Parts Discussed in Thread: TIDA-00947, TIDA-00949

Tool/software: WEBENCH® Design Tools

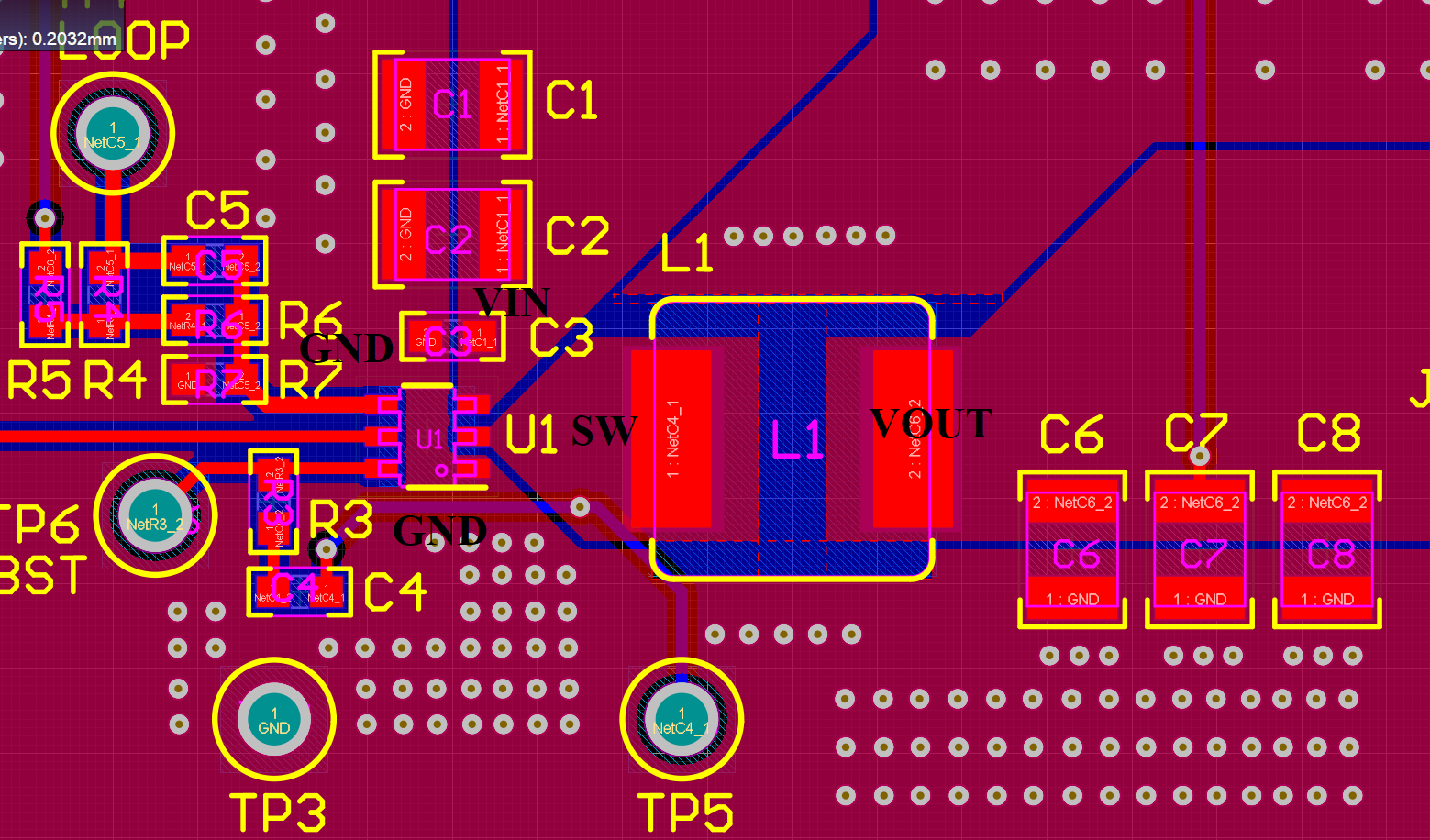

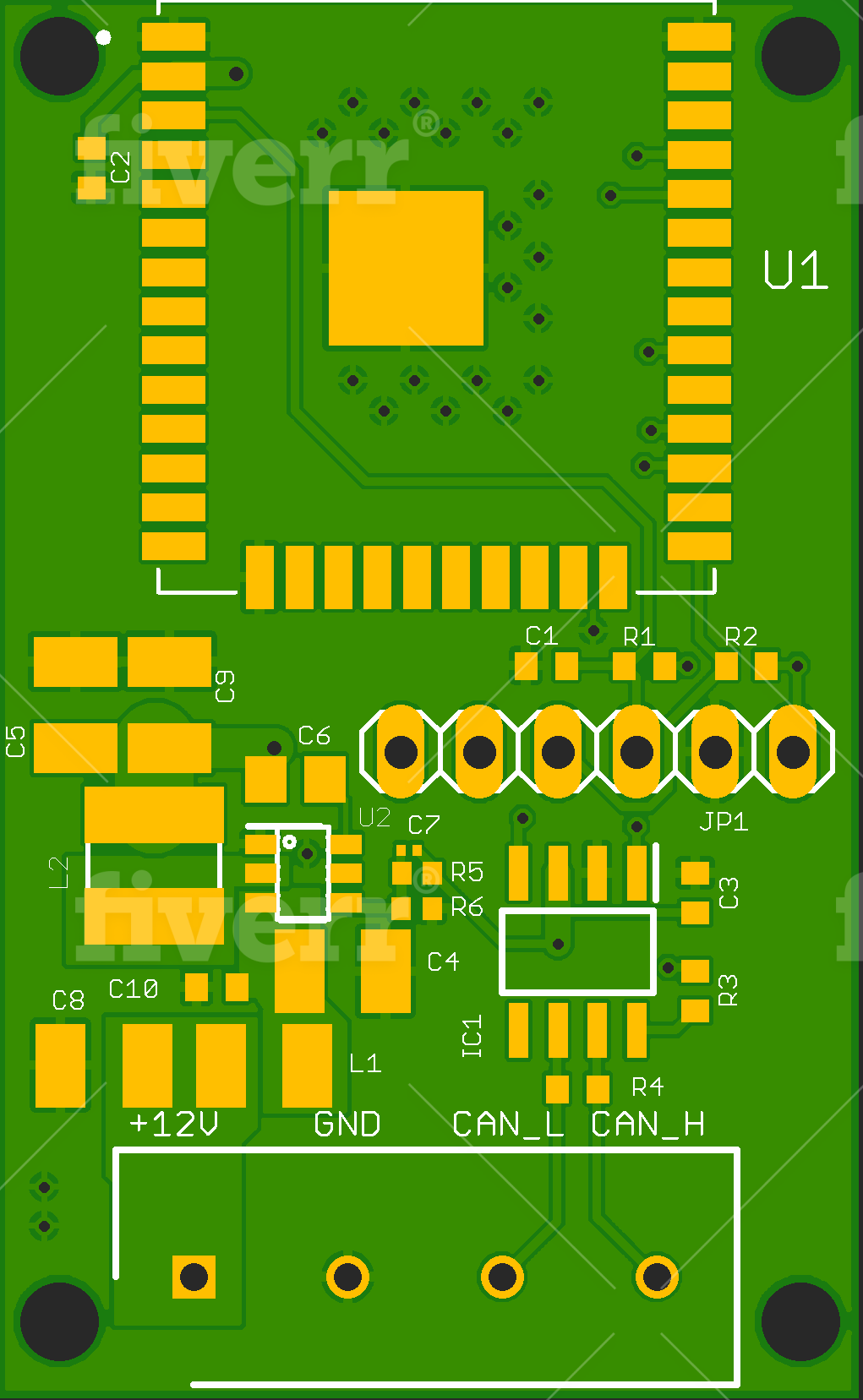

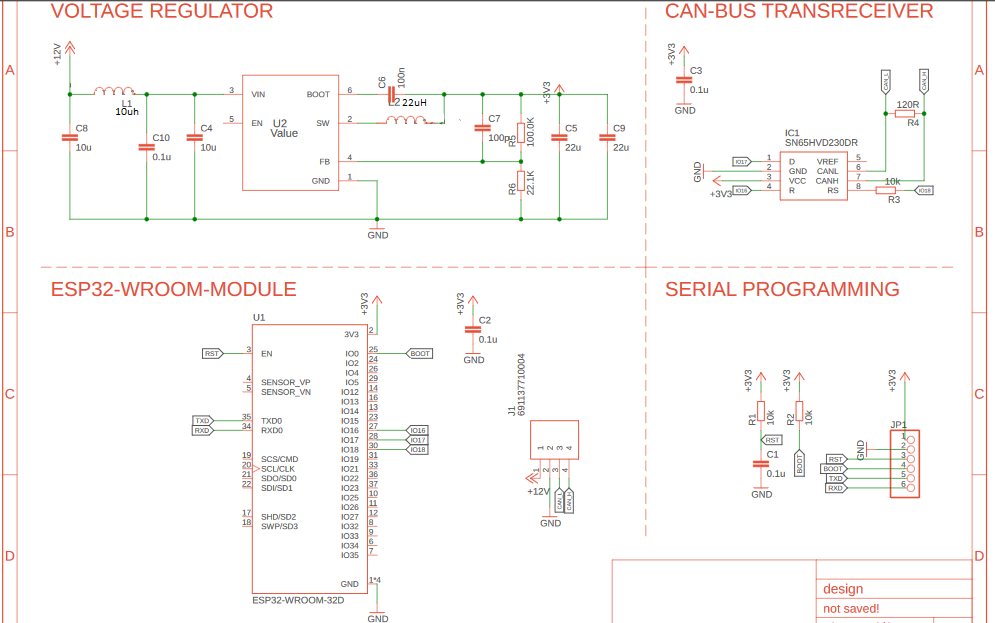

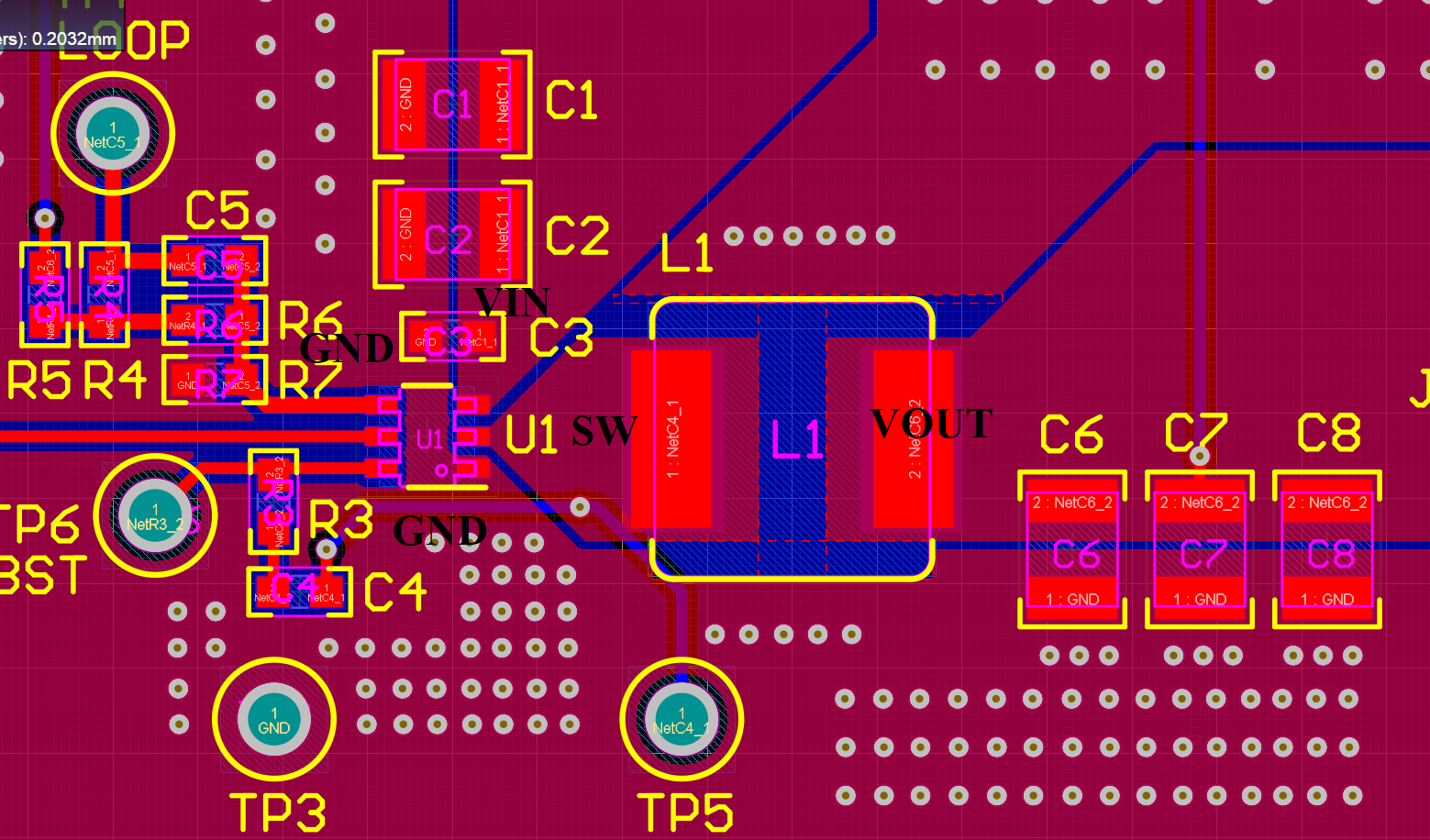

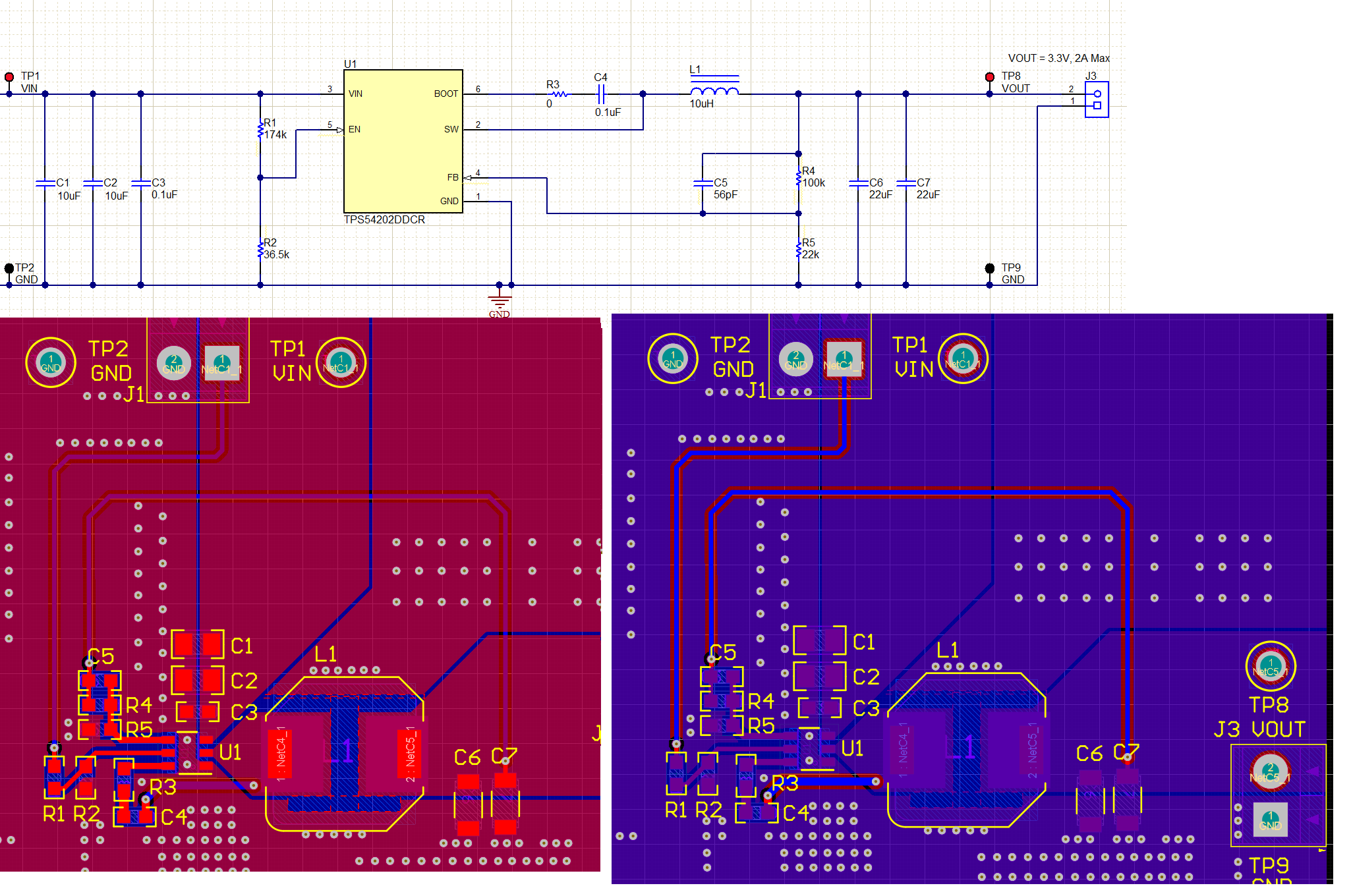

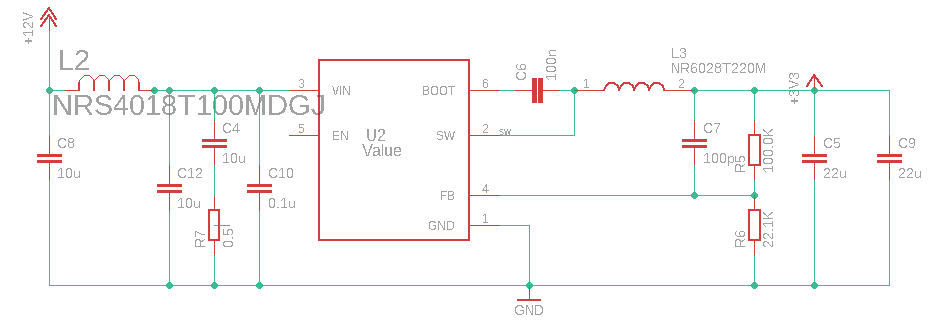

Hi Im begginer in switching power supplies. I need switching regulator which would pass FCC sDoC. In datasheet I find one advised layout of pcb, in webench design tool I get way different pcb layout. Now I found TIDA-00947 which uses TPS54202, it gives way different schematic than webench (different resistor values for fb pin + input filters to pass conducted emision tests). I got confused a lot. I was hoping someone could help me or direct to choose proper schematic + layout for passing FCC sDoC. My input voltage is 14V battery, output needed 3.3v, current 0.1-0.5A, Ill be powering esp32-wroom module and using bluetooth.