Other Parts Discussed in Thread: TPS797

TPS7A03, as well as several similar devices, has active discharge. It is not a feature we see we need or benefit from in our setup, but TPS7A03 appears to be a suitable device in general. Reading about the active discharge in the datasheet we have two questions:

1. It is stated that active discharge is limited to the P-version. We cannot see that there is any other version listed, such as TPS7A0333DQN. Is there?

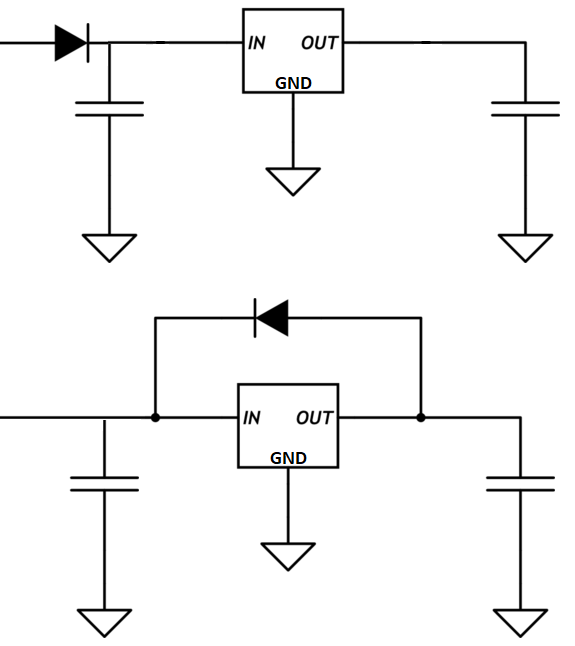

2. We get a bit worried reading 'This reverse current flow can cause damage to the device. Limit reverse current to no more than 5% of the device rated current for a short period of time.'

a) What is the suggested way to achieve this current limiting? We are limited in board space and would gain from the small package of TPS7A03, but would like to avoid having to add supporting components for current limiting.

b) It is stated that 'reverse current can possibly flow'. How should one estimate the actual reverse current (to then judge if it is >10mA or not)? Simulation?

c) What would be an example of 'a short period of time'?

Thanks!