Other Parts Discussed in Thread: LM3410

Hi team,

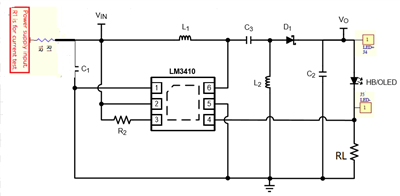

My customer is evaluating LM3410 in SEPIC configuration to power an LED at Vf=3.1V and Vin between 3V to 4.2V. They see an efficiency of only 73%/74%. Can do you have suggestions on why this could be the case and how to increase it?

Thank you,

Franz