Other Parts Discussed in Thread: TL431

Hi,

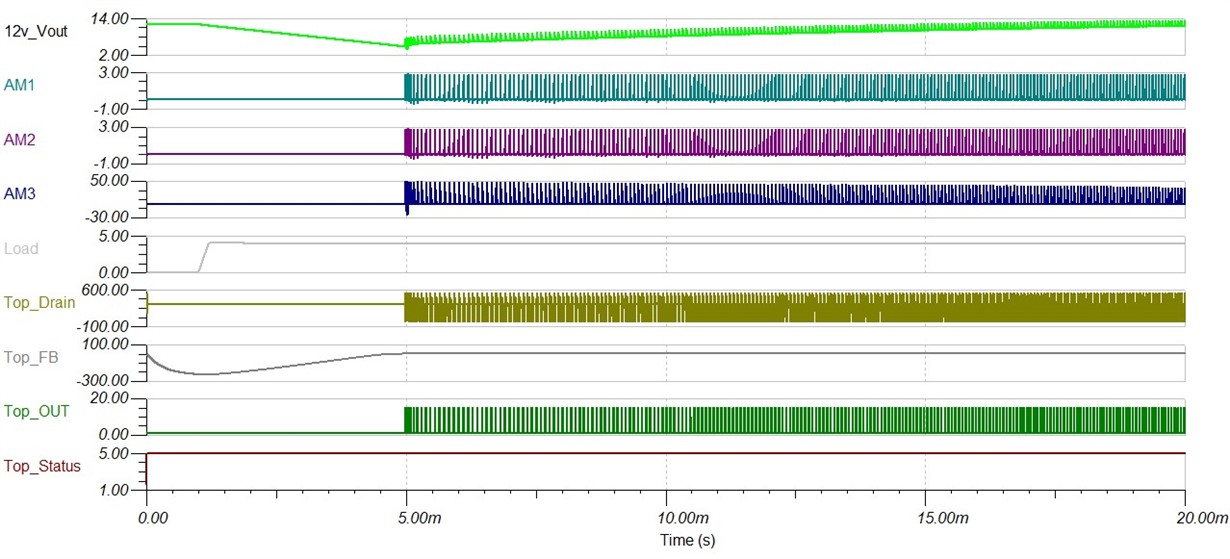

I would like to design a multi-ouput flyback converter based on UCC28600 controller IC. I would also like to simulate the circuit, therefore I was trying to change the transformer to a coupled inductor (because later I will need more than one output) in the given TINA example model to see if it is even possible to simulate the same system but with a coupled inductor with the same properties used with the transformer. Unfortunately, if I use a coupled inductor, the simulation result is completely different than before.

Is there any way to change the transformer to component with which I would be able to simulate successfully a multi-output flyback topology?

Thank you in advance!

Bálint