HI,

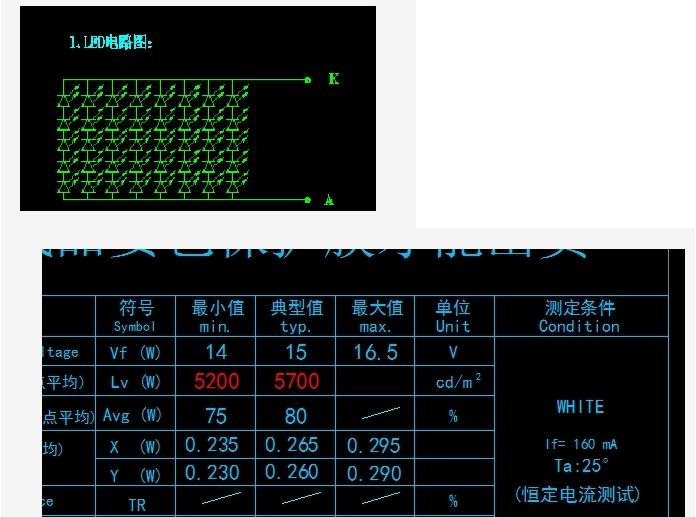

1,Backlight jitter at 200Hz, 6% duty cycle.

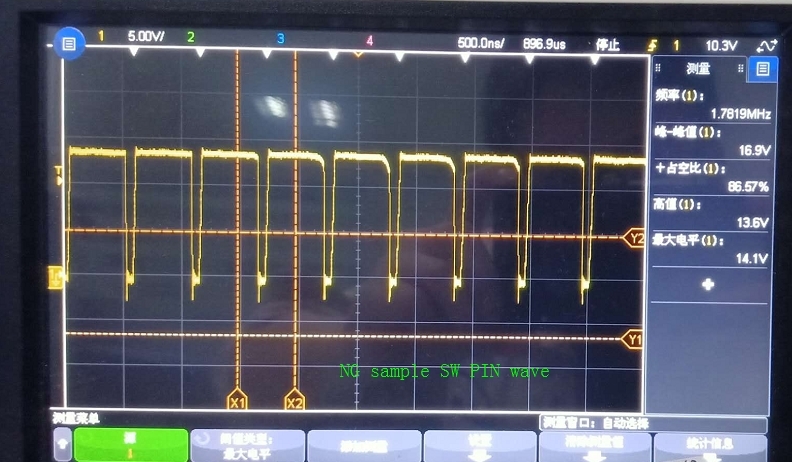

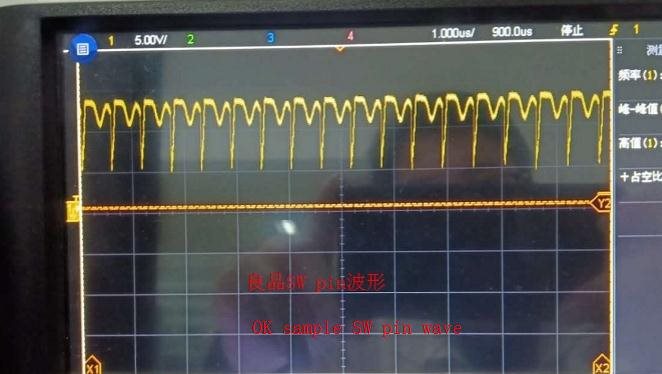

2,Raise the original input voltage from 12V to 14V. At this time, the wave form of the normal pin SW pin pin pin has become straight (because the backlight voltage has been reached), but the wave form of the defective product remains the same

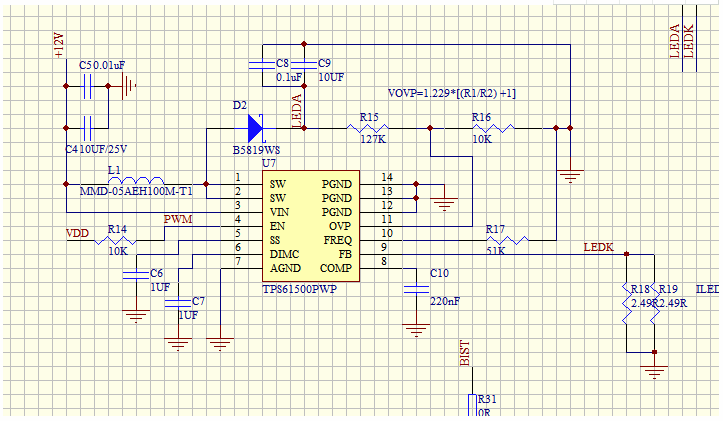

3,Change the resistance of setting the switch frequency from(R17) 51K ohm to 90K ohm. At this time, the defective products are normal and the waveform measurement is normal. However, the different frequency has a great impact on the customer, so it is difficult for the customer to verify again;Please confirm whether our schematic design is OK as shown below?