Other Parts Discussed in Thread: LM36010, TPS630242, TPS63802

Hi Team,

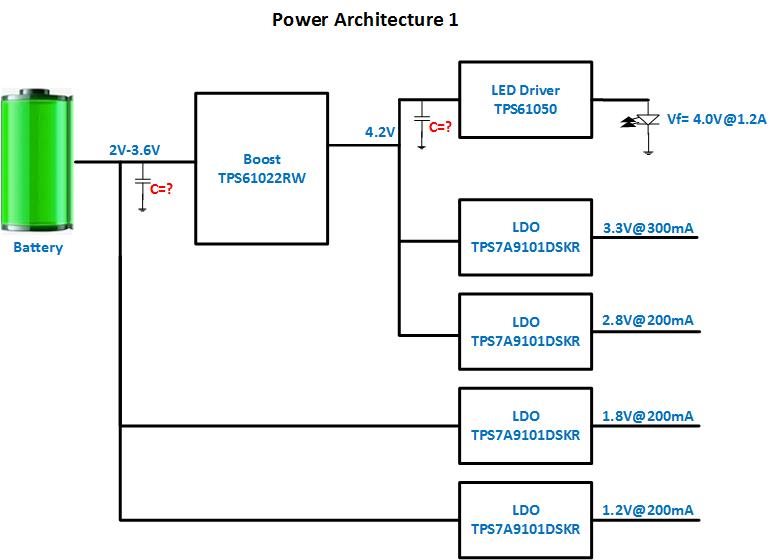

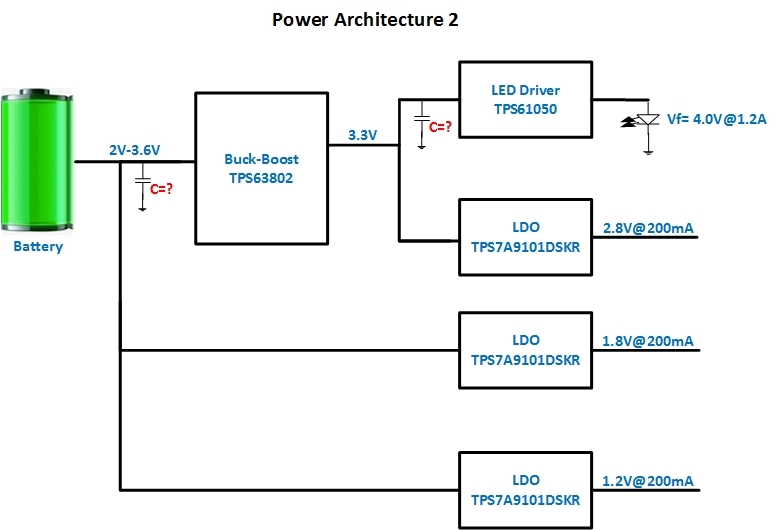

We are designing a camera. In the same we are using flash LED also, and the operating temperature of DUT is -40°C to +85°C. We have worked on two different types of power architecture which are shown below-

We have following doubts-

1) Which Architecture will be more suitable for our design?

2) Flash LED will be turned on for the max time of 250ms. When Flash LED will be turned on it will demand a high inrush current. To provide the same we are planning to provide a bulk capacitor. Please let us know how to calculate the same.

3) In Power Architecture 1 do we need to use inductor at Flash LED driver (TPS61050) since the max forward voltage of LED is 4.0V and the input voltage is 4.2V? So, there is no need to boost the output voltage.

4) What will be the best position of the bulk capacitor to mitigate the effect of inrush at the time of turning on the flash LED ( Near Flash driver IC or near Boost/Buck-boos)?

5) Please suggest if you have a better part (boost, buck-boost and LDO) which is more suitable for our design.