I am using a LMZM23601V5SILT for a MCU aplication, but when i power up the DC/DC convert overheats and the Vout=Vin

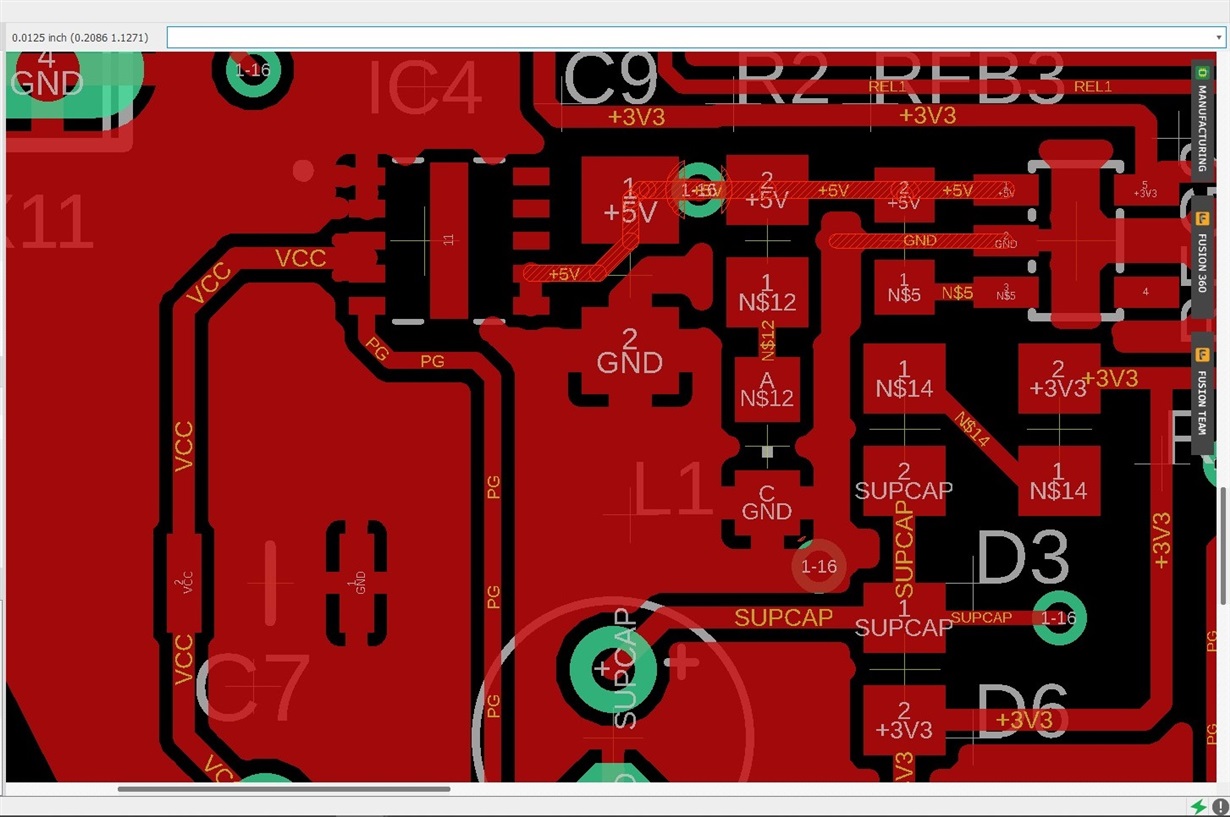

this si my pcb design

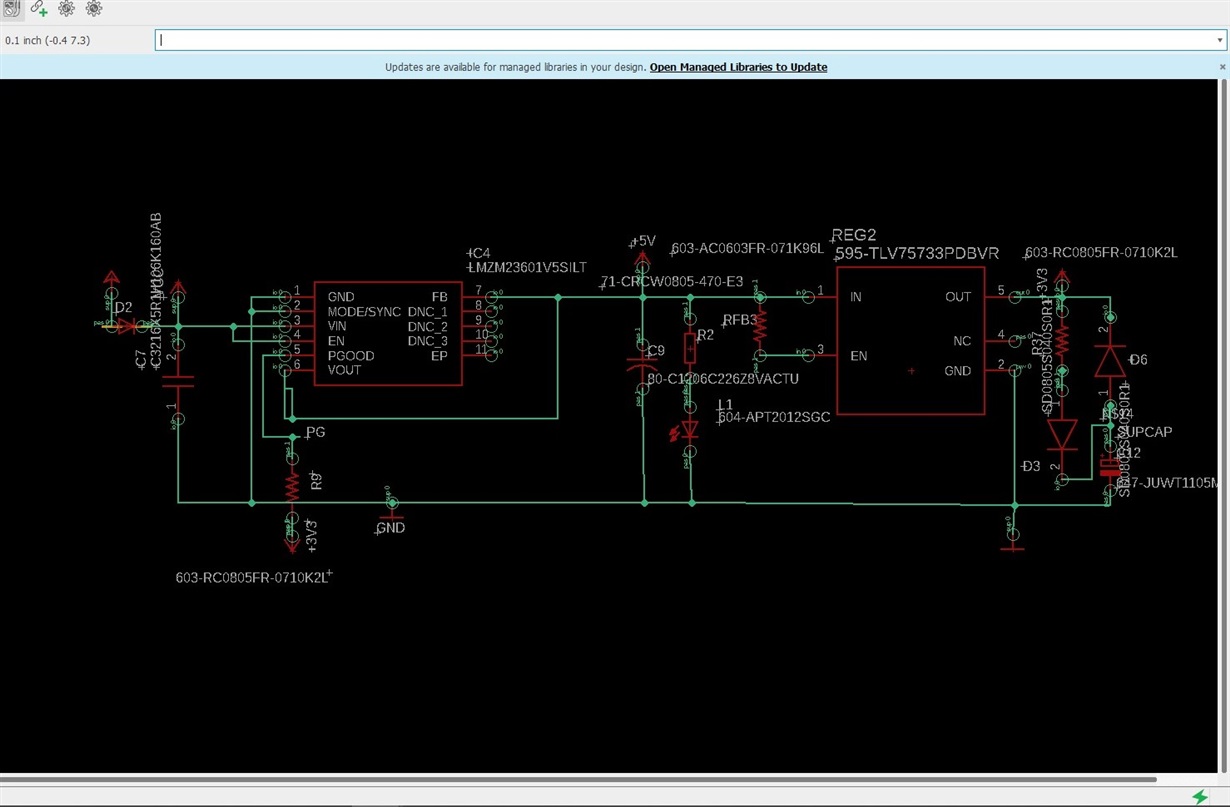

And this it the schematic

So my question

Where wrong i am?

Coul be that thermal pad is'nt are connected to gnd

Regards