Other Parts Discussed in Thread: BQ34Z950

Hello!

We made two pieces (Charger 1, Charger 2) of a dual-channel charger based on BQ 24105. The input voltage of each charger is the same on both channels and is approximately 16 V. (circuit of single channel in application).

I use 3S Li-ion cells 18650 and BQ34Z950. ( ).

).

We have four identical batteries (№№4,5,6,7).

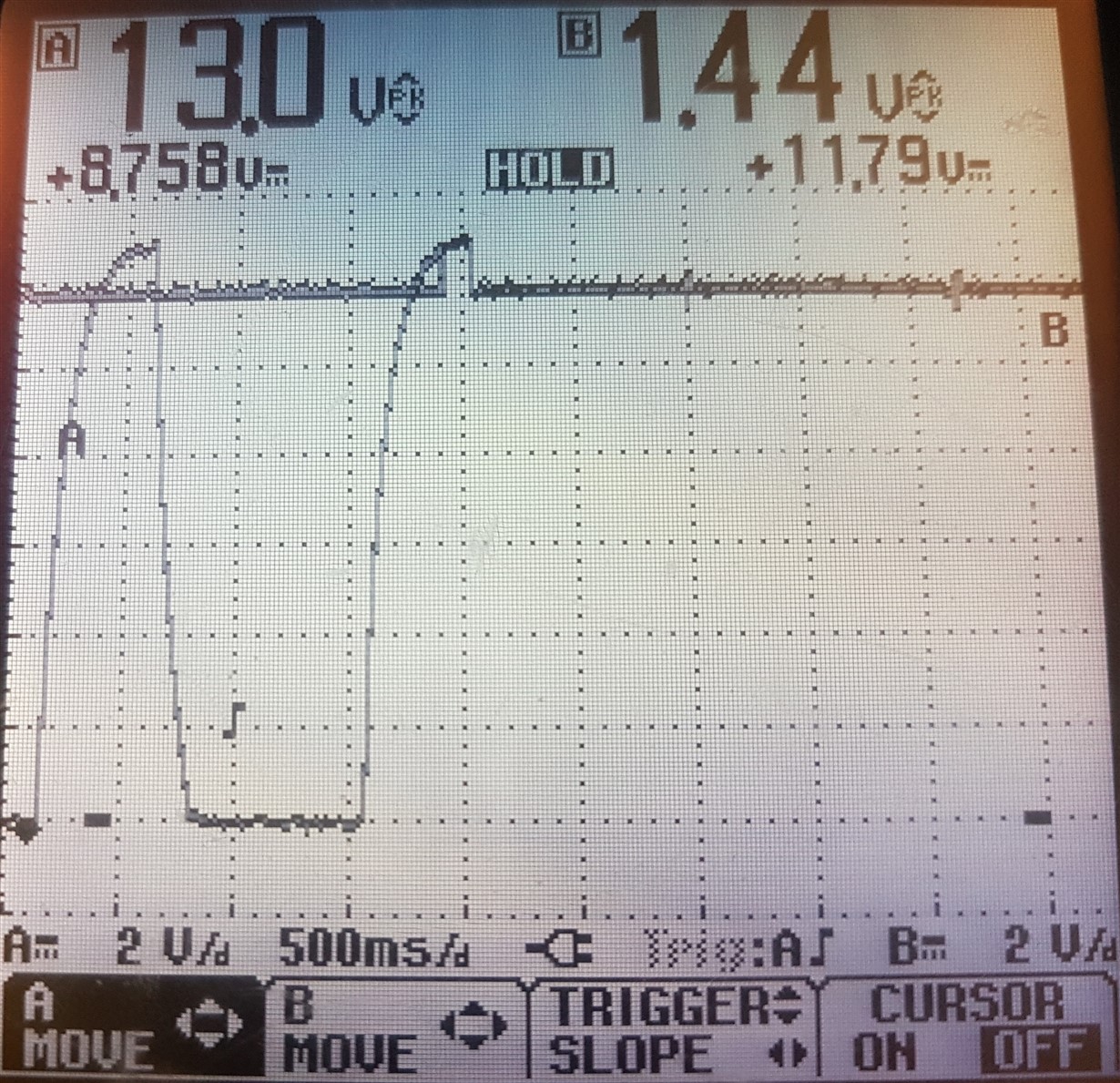

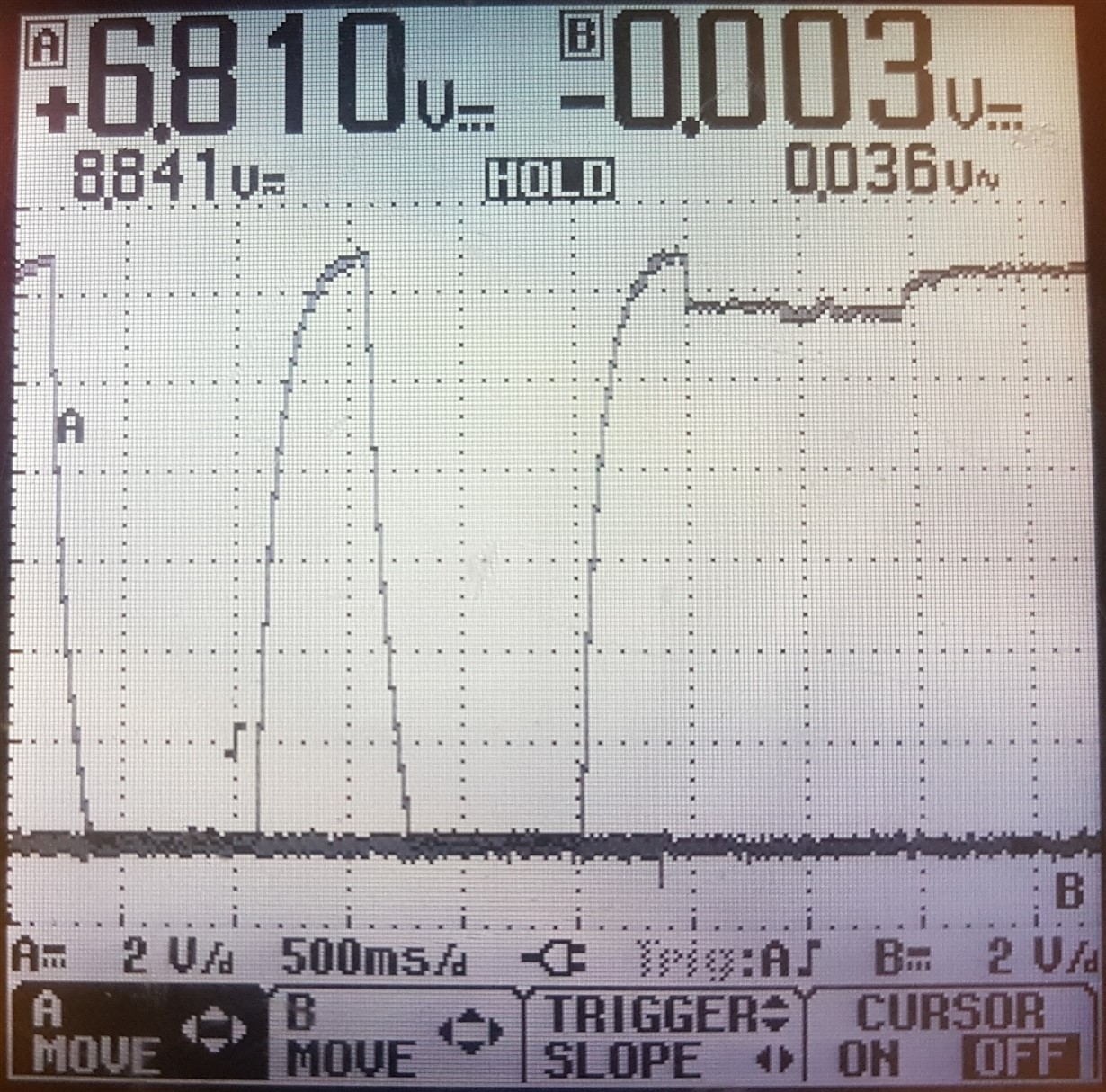

Quite often, the charging process does not occur properly - when the battery is connected, stat1 constantly blinks (battery detection process).

Before creating this post, I tried to connect each battery to each slot of both chargers. Connected three times with a wait of 5-10 seconds. Designed the results in a table.

At other times, the results may vary slightly. If charging still starts (stat1 is on), it does not always end successfully (at the end, instead of lighting of stat 2, blinking of stat1 starts).

The wires are quite long - about 40 cm per bat + and 40 cm per bat- (from the board with bq34z950 to the board with bq24105). wires 22 AWG.