So I am thinking maybe I need to go to a higher power part, but just want to check if there is anything I can do otherwise. I have a design that takes in 20V from a battery and drops it down to 12V to a 3.5A blower fan.

So the part is getting very hot and I was thinking I wasn't that close to the 5A max, but maybe because of the voltages I am using it dissipates too much power. I also only have a 2 layer board and didn't realize they were assuming you use 4 layers.

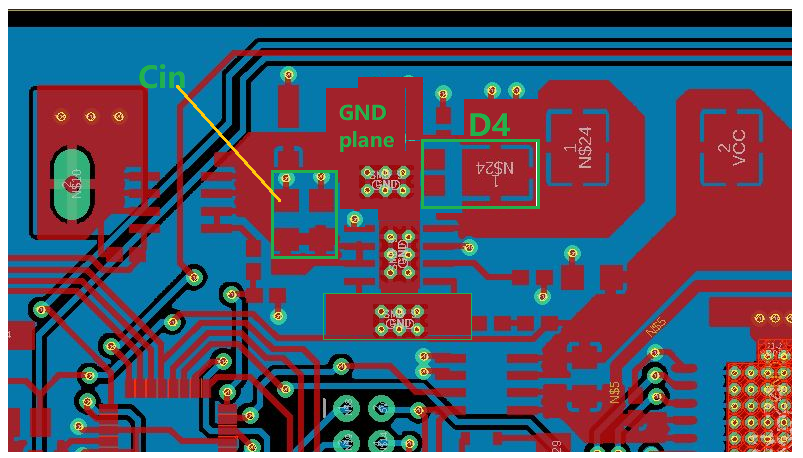

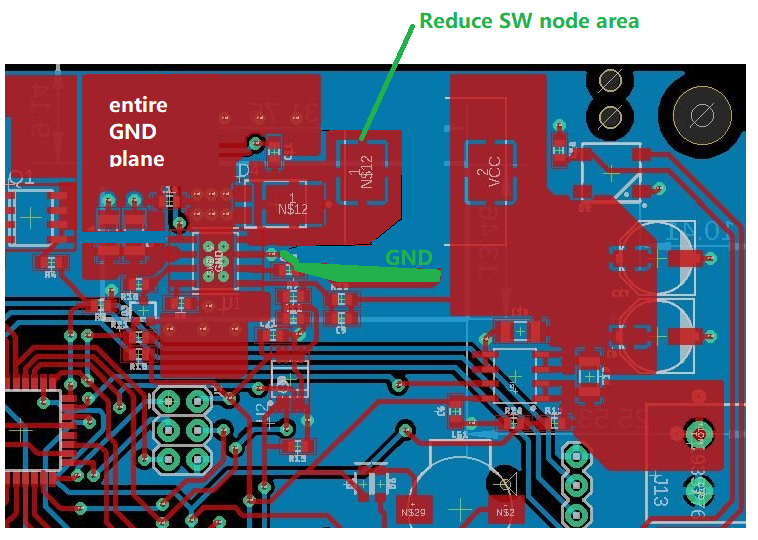

Layout.