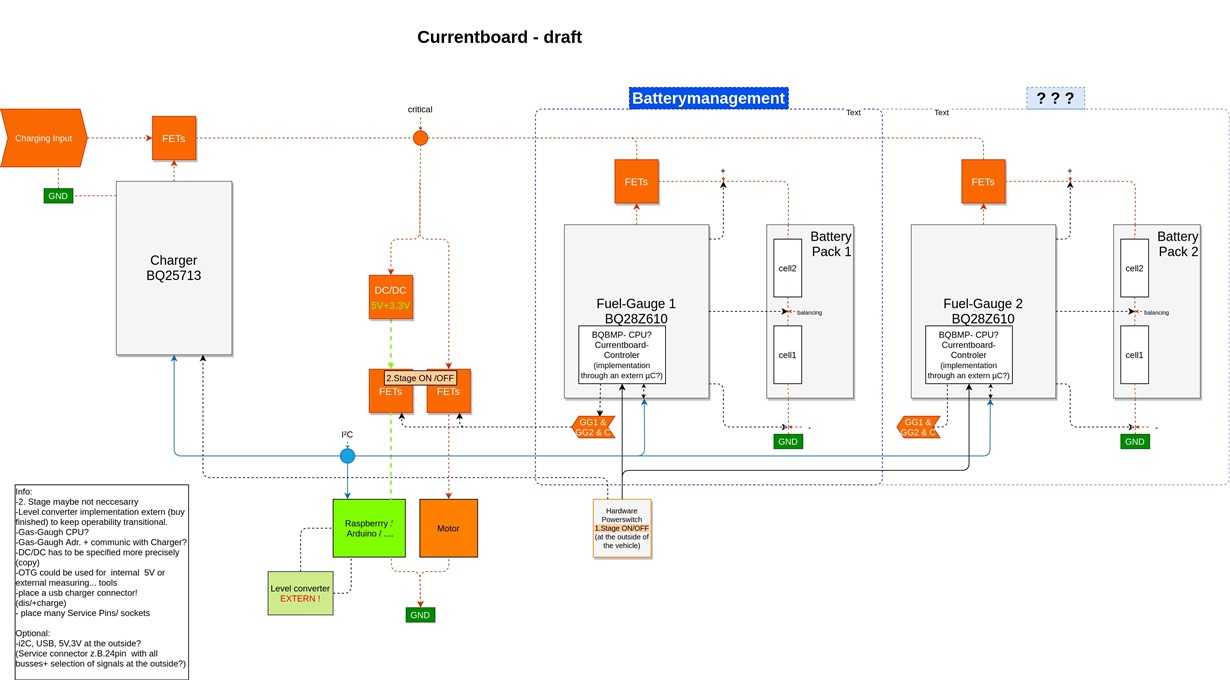

Other Parts Discussed in Thread: BQ25713, EV2400, BQSTUDIO, BQ28Z610

Hi, :)

I am a student at Hochschule München (Applied Sciences) and involved in a project on the Car2X topic.

For this we have three 1:10 scale model vehicles in operation.

The next step for our team is the integration of a battery management and charging system for LiPo batteries.

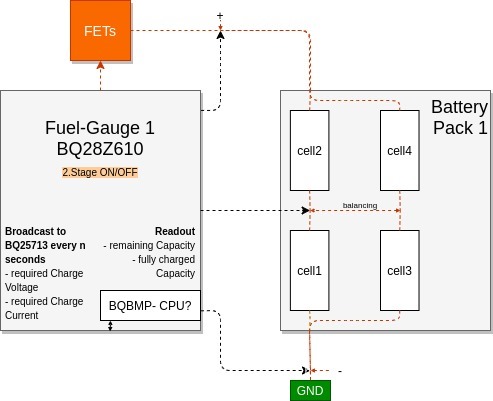

The target battery configuration is 2S 2P. (4 cells of 3.7V 25C 4200mAh / only 2s is also an option but less suitable.)

We want to do this as efficiently as possible.

After a lot of research we came to the conclusion that a combination of the BQ28Z610-R1 and BQ25713 could be a nice and powerful combination for us.

(We know that we will need bqstudio + EV2400)

(The motor is controlled over a h-bridge)

further Conditions:

- Each cell should be balanced

- The capacity/charge status + voltages should be monitored and readable over I2C.

- Overcharge / current protection

- Deep charge protection

- Low self-consumption when switched off

- little space requirement (high integration density)

- (motor needs ~14A , 5V+3,3V ~5A load)

nice to haves/ questions: - It would be nice, if we could use a integrated processing unit to control two additional FET's, for switching the motor and the µC(Raspberry+Arduino..) Supply, without adding a µC for this purpose.

- Is the BQBMP processor capable to do that for us? (or a charger?)

- is it possible to program some additional lines of code to switch off the motor at a battery level <=10% an the other loads(µC) at a battery level <=5%

- +sending a warning according to these two capacity-levels (over I2C)

- Is it possible to use two BQ28Z610-R1 gas gauges together?

- to change their addresses(if needed)

- that they can communicate the correct current and voltage... values to the charger

- can they add up the values?

- or is the charger capable to do so?

- how would it be possible to balance and protect all cells and measure their capacity, when it comes to parallelization?

- Is the point in the draft, which is marked as "critical" the position where the load should be placed?

- Is their an other solution we should prefer?

Its a pity, that it seams like we're just getting a good 2s configuration this way.

I would be happy if you could give us some answers or advice's here.

Sincerely yours

Daniel Kerz