Hi there,

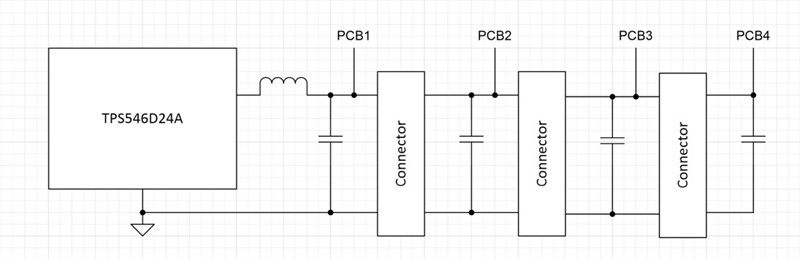

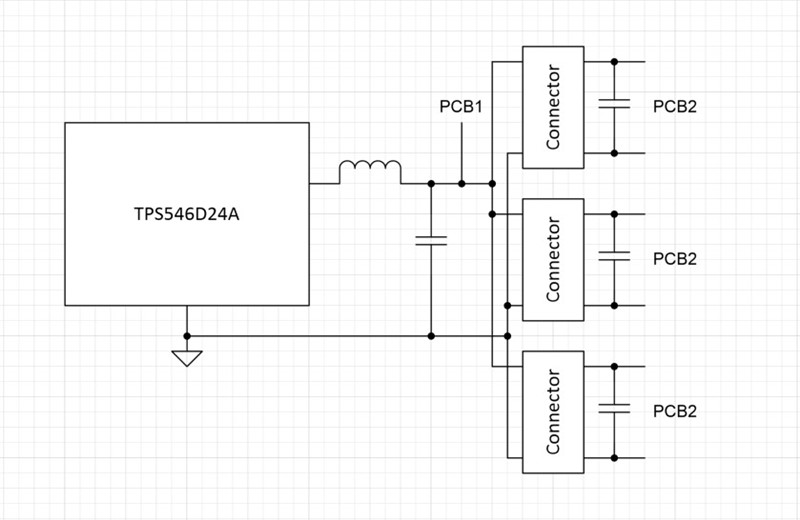

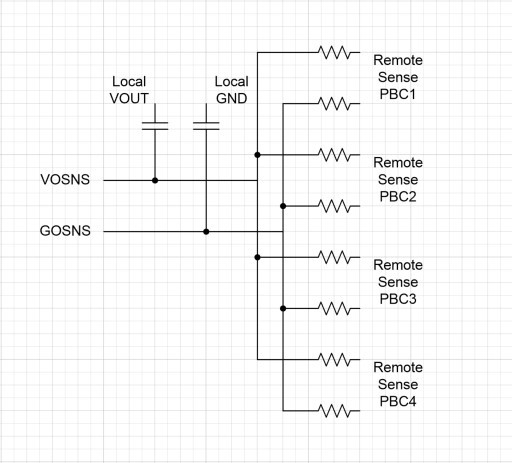

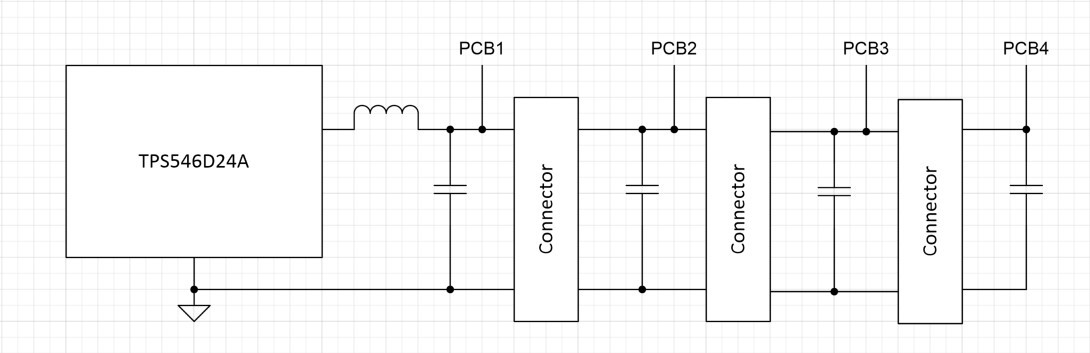

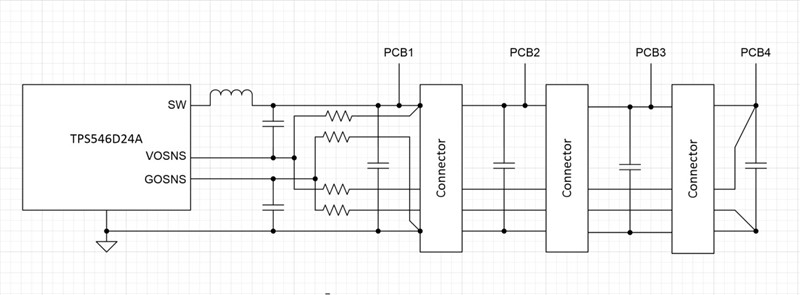

In my application. The output voltage will cross 4 PCB boards and 3 connectors. The distance is about 50cm. So I want to know, is it OK to connect senseN and senseP to the terminal device. Does the internal conmensation components could make the loop stable. If not. Can I add Op Amp to feedback the senseN and senseP to improve the stability?

The Output voltage range is: 1.2V to 4V

The max current is : 30A

The max output voltage ripple is: +-100mV

If you have any reference or similar case please let me know.

Best Regards,

Ricardo