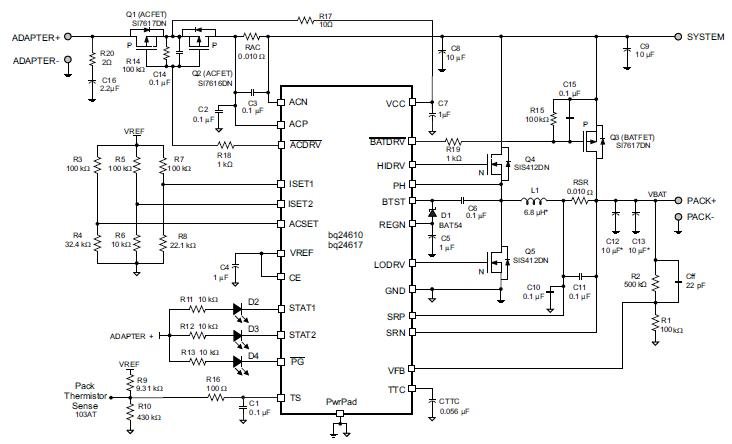

Dear experts, please refer to below figure. I set the fast-charging current to 50mA and set precharge current to 10mA. R7 is 100K ohm, R8 is 43.2K ohm, R5 is 100K ohm, R6 is 43.2K ohm and RSR is 1 ohm. L1 is 6.8uH. The ADAPTER+ is 16.8V and PACK+ is 11V(3 *Li iron battery). The real fast-charging current is about 12mA. The fast-charging current will depent on PACK+ voltage. When I increase the PACK+ voltage, the fast-charging current will reduce. When I reduce the PACK+ voltage, the fast-charging current will increase. Could you give me some suggestion how to achieve the 50mA fast-charging current and 10mA precharge current. Thanks.

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.