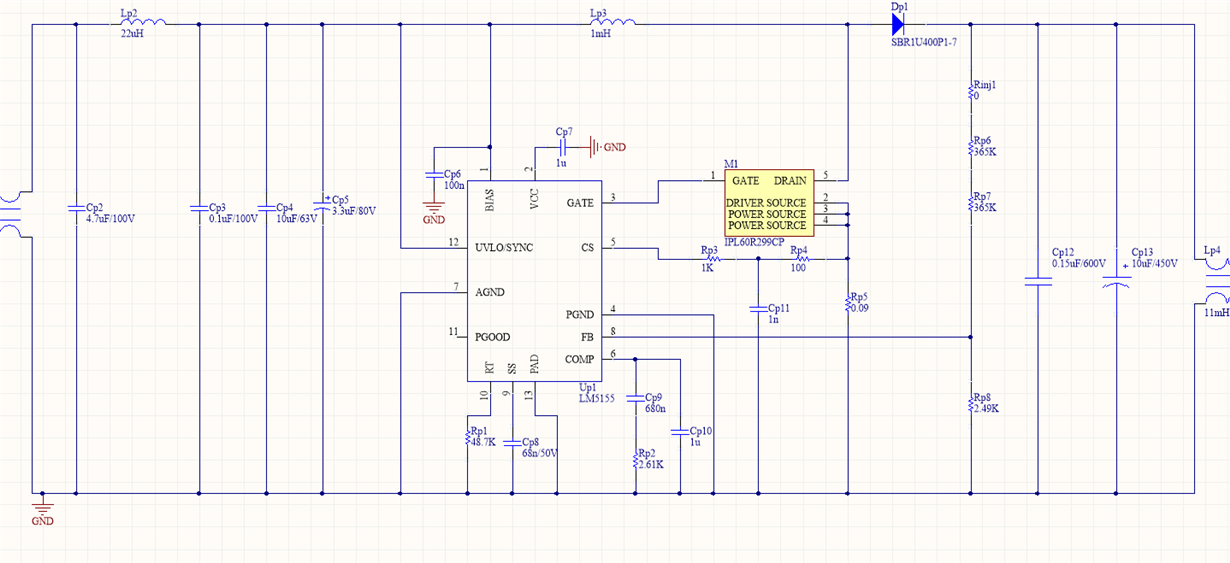

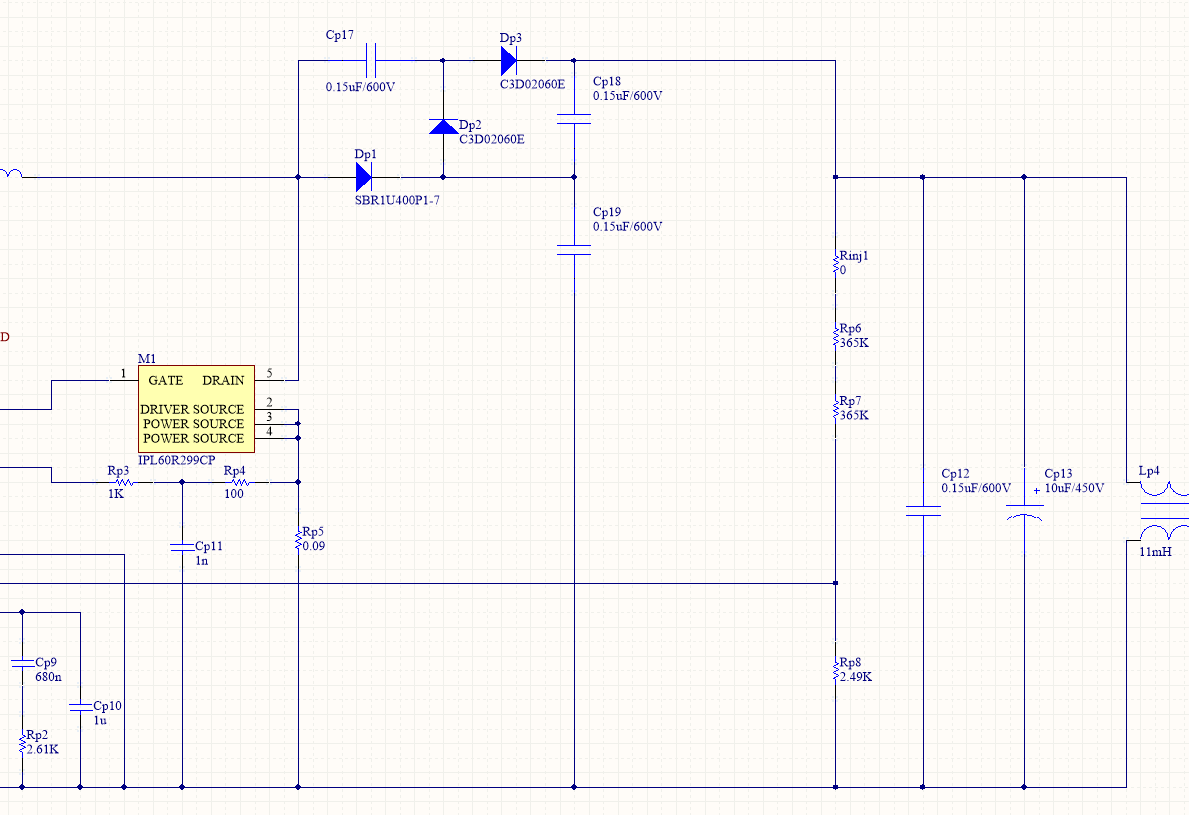

I'm having an issue with the following boost design. This is basically straight out of the Webench software with minor adjustments. Input voltage is 35-45V, Output voltage is 300V, output current is 20-30mA.

On power-up the LM5155 is destroyed with a spark. Dp1 fails short-circtui as well. I'm not sure what happens first. Dp1 is 400V rated, so it should be within it's operating margins. I've tested this circuit with Rp6 shorted and it worked fine. Output was around 145V.

Any ideas as to why this circuit fails at 300V output?