Other Parts Discussed in Thread: TPS63030, , TPS63060, TPS61030

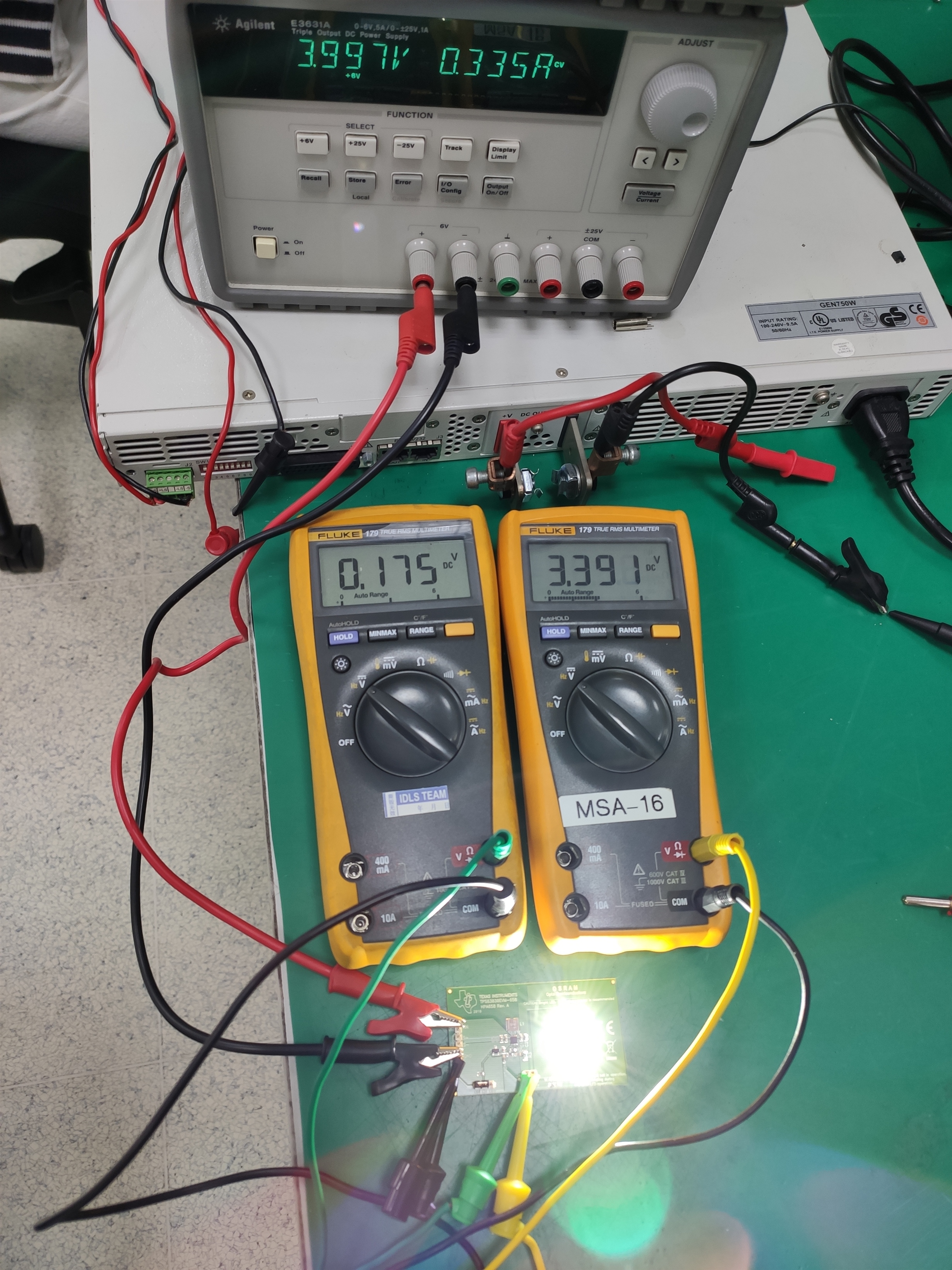

I am using the TPS63030EVM-658 as an evaluation method for an LED system (driving 4 white LEDs in parallel). I have noted in testing that the TPS63030 efficiency is really bad, on the order of 60% best case, when using the TPS63030EVM-658 board. This has been duplicated across multiple test runs. The only modification to the board was removal of R6 to allow current measurement.

Becasuse I was concerned that the part couldn't handle the current, having run into this on other TI parts, I spun my own board using the TPS63060 using a similar scheme, albeit with some efficiency improvements. The results are clear that the TPS63060 (or my design) is far superior to that on the EVM. Here are the discharge curves for a single Li-Ion 18650 cell.

Any thoughts on causes for this? I'm happy to try another board if TI will provide it.